Fe-doped biochar loaded TiO2 composite material preparation method and application

A technology of composite materials and biochar, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as separation and recovery difficulties, and achieve rapid preparation, short production cycle, preparation process and Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

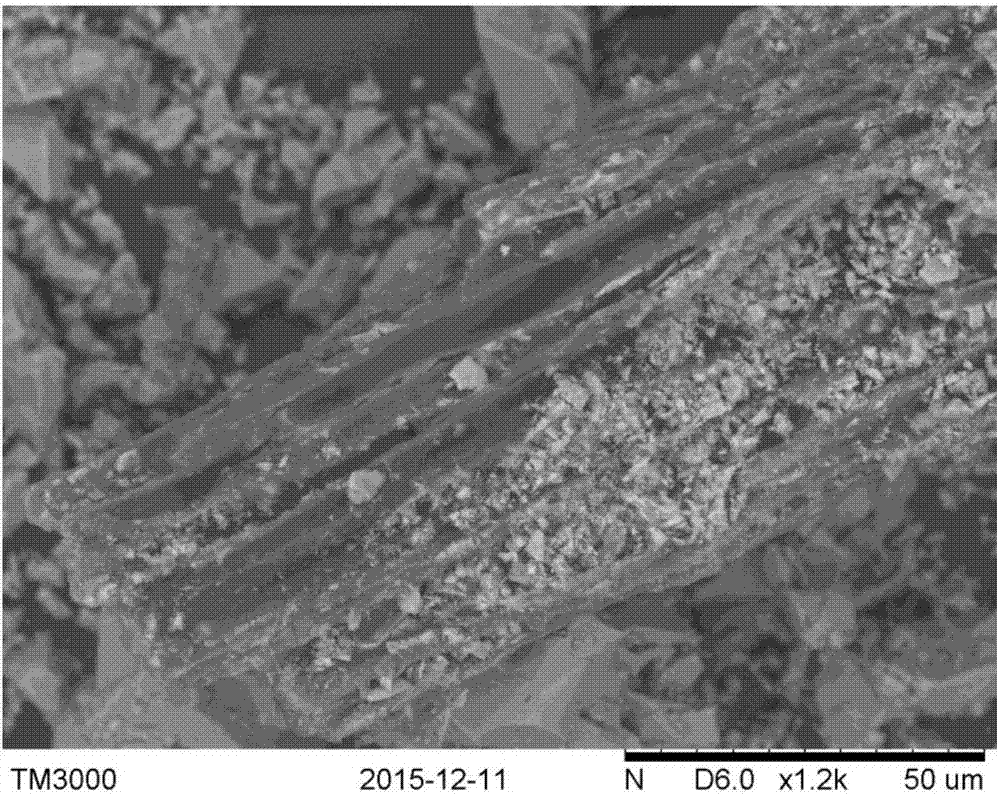

[0027] A kind of Fe-doped biochar loaded TiO according to the present invention 2 The preparation of the composite material, biochar raw material selects the ramie stalk that removes leaf and bark, and specific preparation method is as follows:

[0028] The biomass raw material was washed with deionized water, then dried at 80°C for 24 hours, the dried biomass was pulverized, and passed through a 2mm sieve to obtain biomass powder; 10mL of tetra-n-butyl titanate and 0.101g of Ferric nitrate was slowly added in 15ml of absolute ethanol, and the mixed solution was stirred on a constant temperature magnetic stirrer at a speed of 200 rpm for 20min to form a yellow clear solution; 1.5g of the biomass powder obtained in step (1) was added and stirred for 30min to obtain a suspension Liquid A. Mix 5ml of glacial acetic acid, 5mL of deionized water and 5mL of absolute ethanol, and stir the mixture on a constant temperature magnetic stirrer at a speed of 200 rpm for 10 minutes to obta...

Embodiment 2

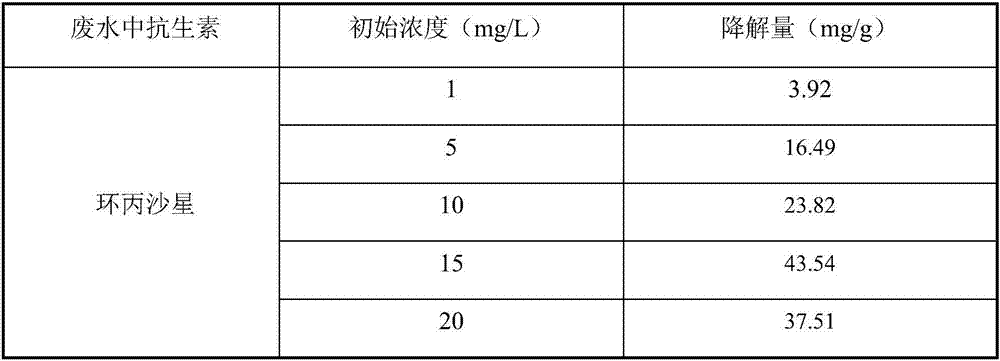

[0031] Fe-doped biochar loaded TiO of the present invention 2 The composite material treatment of ciprofloxacin in waste water comprises the following steps:

[0032] Get 50mL initial concentration and be the ciprofloxacin solution of 1~20mg / L, add the Fe-doped biochar loading TiO that embodiment 1 makes 2 The composite material, the amount of the adsorbent is 0.01g, and the photocatalytic reaction is carried out in a constant temperature incubator at 27 °C. After 2 hours, the photocatalyst is separated from the wastewater by centrifugation, and the photocatalyst in the wastewater is measured at 530nm by a spectrophotometer. The content of degraded ciprofloxacin, the calculated degradation results are shown in table 1:

[0033] Table 1: Photocatalyst degradation rate data under different initial concentrations of ciprofloxacin

[0034]

[0035]As can be seen from Table 1, the catalyst agent has a degradation capacity of 43.54 mg / g under the condition of 15 mg / L at the ini...

Embodiment 3

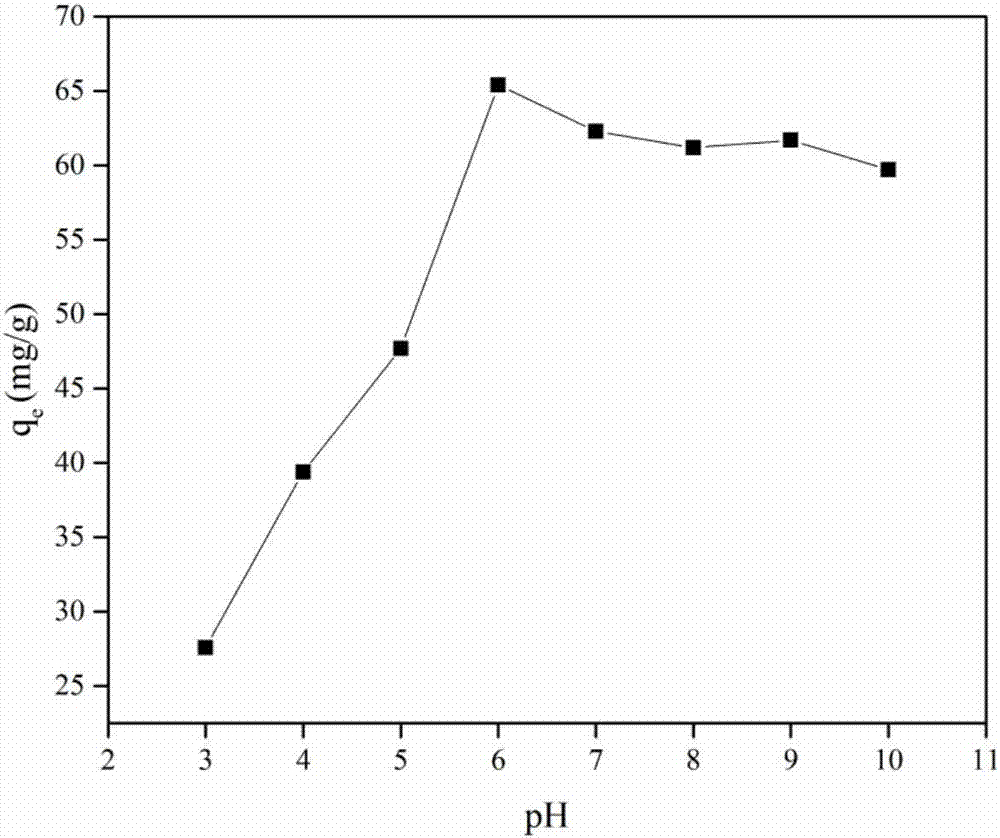

[0037] Fe-doped biochar loaded TiO of the present invention 2 The composite material treatment of ciprofloxacin in waste water comprises the following steps:

[0038] Get 50mL initial concentration and be the ciprofloxacin solution of 500mg / L, add the Fe-doped biochar loaded TiO that embodiment 1 makes Composite material, the consumption of this catalyst is 0.005g, 0.01g, 0.015g, at 27 ℃ constant temperature The photocatalytic reaction was carried out in the incubator, and after 2 hours, the photocatalyst was separated from the wastewater by centrifugation, and the content of undegraded ciprofloxacin in the wastewater was measured with a spectrophotometer at 530nm. The calculated degradation results are shown in Table 2 Shown:

[0039] Table 2: Degradation data of ciprofloxacin under different catalyst amounts

[0040] Catalyst dosage (g) 0.005 0.01 0.015 Degradation amount (mg / g) 28.53 43.54 19.63

[0041] It can be seen from Table 2 that the degra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com