A kind of ferrierite molecular sieve and its preparation method and application

A kind of technology of ferrierite and molecular sieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

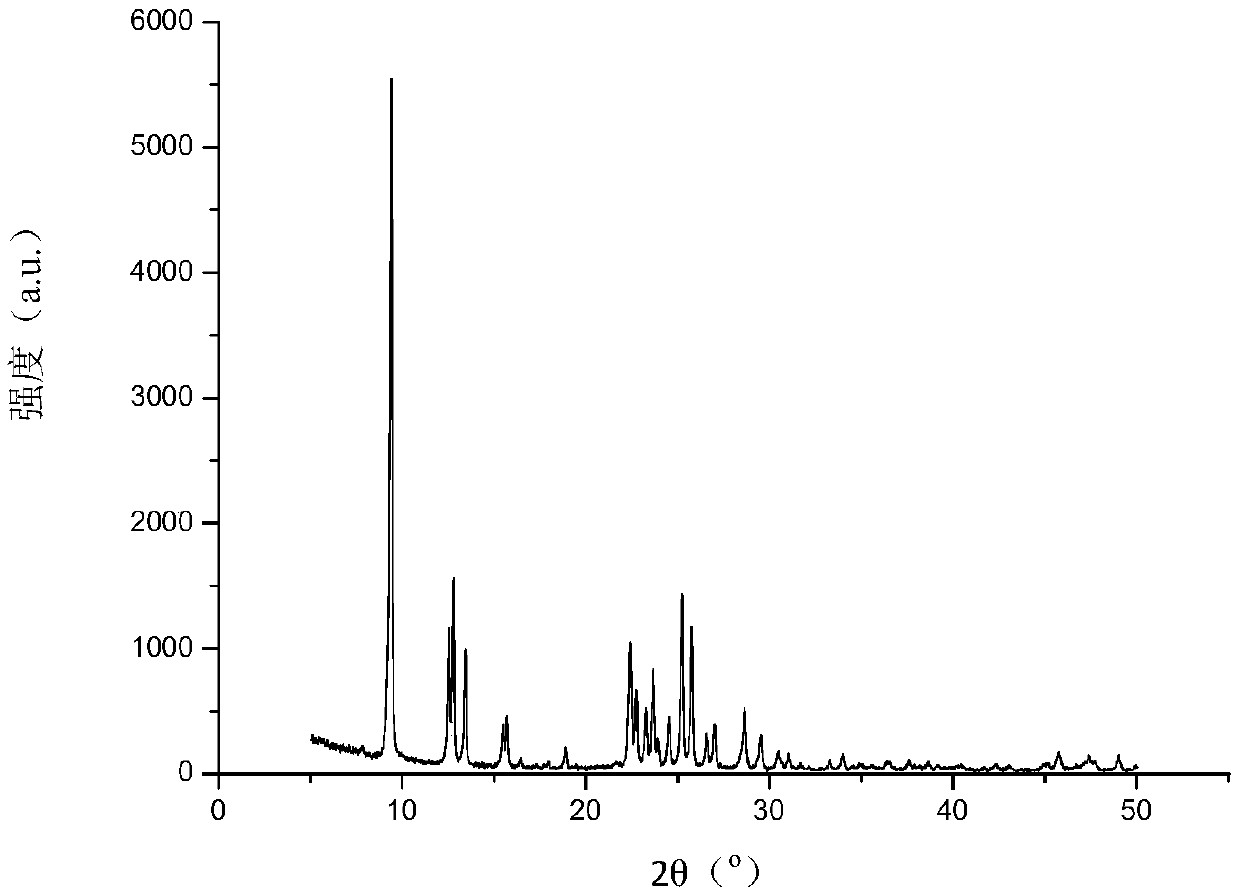

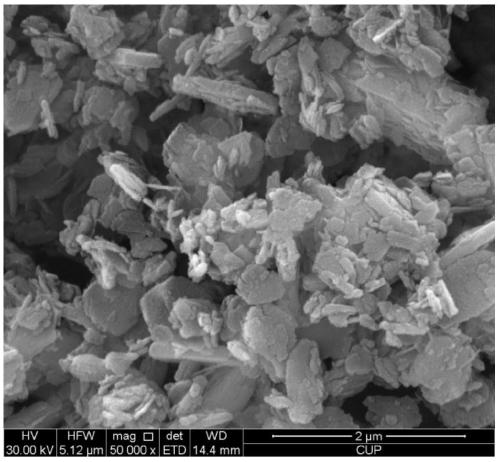

[0055] This embodiment provides a ferrierite molecular sieve and a preparation method thereof.

[0056] Dissolve 3.13 grams of hydrated aluminum sulfate in 120 grams of deionized water, add 15.6 grams of pyridine to the solution, and then add 26.91 grams of 98% sulfuric acid, stir for half an hour to fully mix the solution, and slowly add sodium silicate 80.1 g (SiO 2 and Na 2 O content is 22.4% and 21.8% respectively, and the rest is water), and the solution is stirred for half an hour to form a uniform sol. The molar composition of this sol is: 63.67SiO 2 :1.0Al 2 o 3 :3.18Na 2 O:1419H 2 O: 42.0R, R is pyridine in the formula, and this sol pH value is 13.3.

[0057] The sol was put into an autoclave, pre-crystallized at 110°C for 5 hours, and then heated to 170°C for hydrothermal reaction for 24 hours. Molecular sieves were recovered by the conventional method described in Comparative Example 1.

[0058] Take more than 10 grams of the prepared molecular sieve and ad...

Embodiment 2

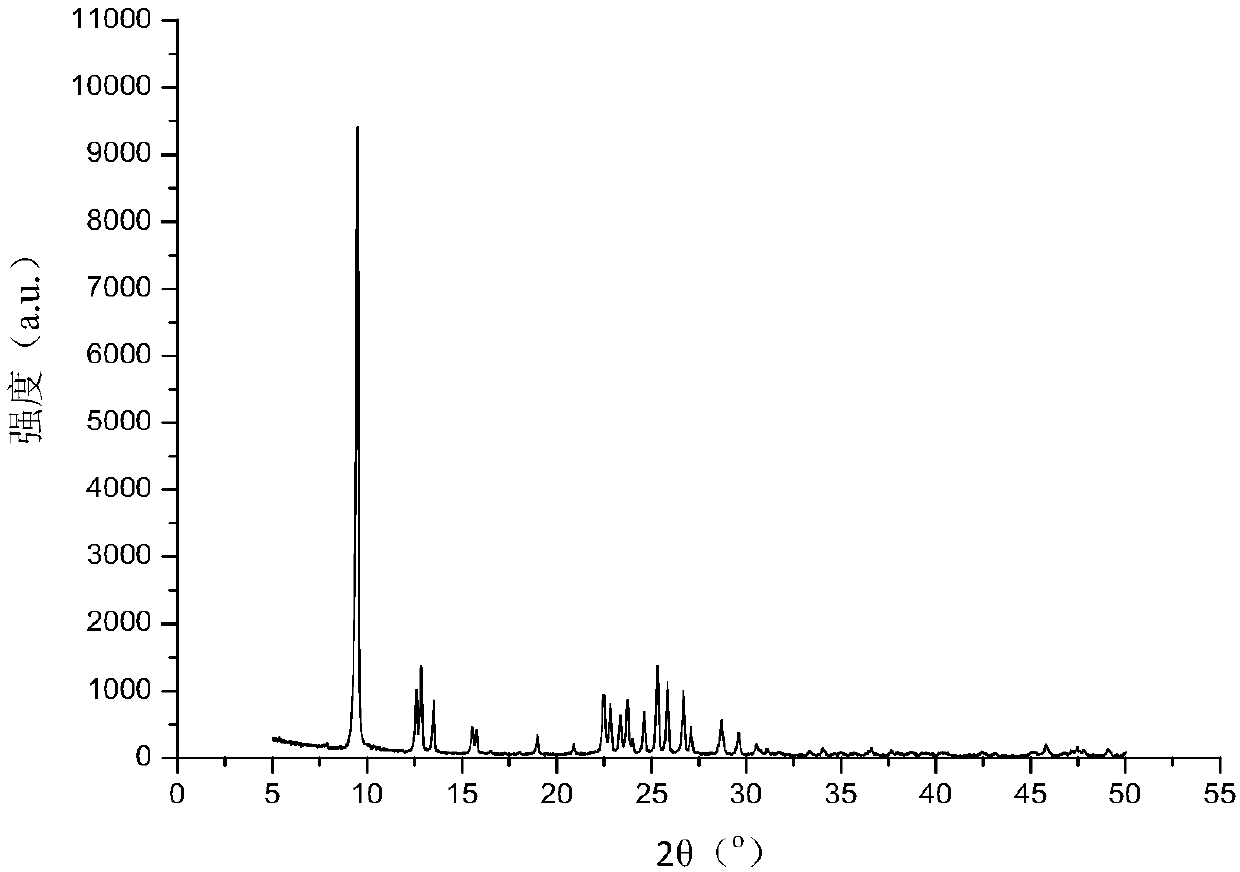

[0060] This embodiment provides a ferrierite molecular sieve and a preparation method thereof.

[0061] Dissolve 5.13 grams of sodium hydroxide in 300 grams of deionized water, add 5.5 grams of aluminum sulfate hydrate to the solution, then add 22.7 grams of pyridine, slowly add 93.3 grams of silica sol (SiO 2 The content is 40%, the rest is water), and the solution is stirred for half an hour to form a uniform sol. The molar composition of the sol is: 75.4SiO 2 :1.0Al 2 o 3 :3.77Na 2 O:2260H 2 O:37.1R, R is pyridine in the formula, and the pH value of this sol is 12.9.

[0062] The sol was put into an autoclave for pre-crystallization at 120°C for 2 hours, then heated to 180°C for hydrothermal reaction for 36 hours. Molecular sieves were recovered by the conventional method described in Comparative Example 1.

[0063] Take 10 grams of the molecular sieve prepared above and add it to 120ml of nitric acid solution with a mass fraction of 1.5wt.%. After stirring at 90°C f...

Embodiment 3

[0065] This embodiment provides a ferrierite molecular sieve and a preparation method thereof.

[0066] Dissolve 11.35 grams of sodium hydroxide in 270 grams of deionized water, add 2.0 grams of aluminum trichloride to the solution, then add 48.41 grams of n-butylamine, slowly add 100.3 grams of silica sol (SiO 2 The content is 36.32%, the rest is water), and the solution is stirred for half an hour to form a uniform sol. The molar composition of the sol is: 40.5SiO 2 :1.0Al 2 o 3 :18.9Na 2 O:300H 2 O:44.2R, R is n-butylamine in the formula, and this sol pH value is 13.8.

[0067] The sol was put into an autoclave for pre-crystallization at 140°C for 1 hour, then heated to 170°C for hydrothermal reaction for 54 hours. Molecular sieves were recovered by the conventional method described in Comparative Example 1.

[0068]Take 10 grams of the molecular sieve prepared above and add it to 80ml of acetic acid solution with a mass fraction of 2.5wt.%. After stirring at 70°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com