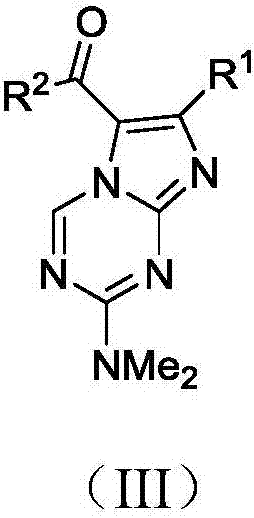

Imidazole-triazine type compound and preparation method and application thereof

A technology of s-triazine and imidazolium, applied to imidazo-s-triazine compounds and the fields of preparation and application thereof, can solve the problems of difficult control of reaction conditions, high toxicity, poor yield and the like, and achieves wide industrial application prospects , easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

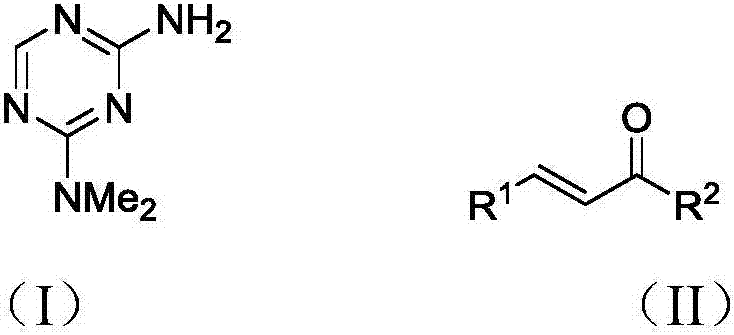

[0028] Example 1 Preparation of 2-amino-1,3,5-triazine compounds

[0029] Taking 2-amino-4-dimethylamino-1,3,5-triazine as an example, its preparation method is:

[0030] Mix metformin hydrochloride (1.6616g, 10.0323mmol), sodium methoxide (1.6200g, 29.9868mmol) in methanol (25mL), react at room temperature for 4h, add methyl formate (1.5011g , 24.9967mmol), continued the reaction at room temperature for 24h, evaporated the solvent under reduced pressure, added 10mL of water, filtered, and recrystallized the solid to obtain the target compound, 1.2826g, with a yield of 92%.

Embodiment 2

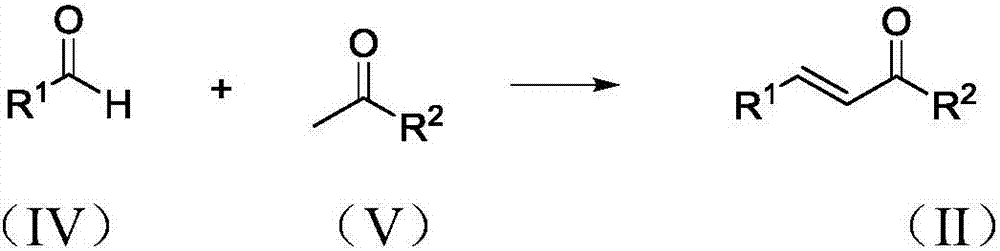

[0031] Example 2 Preparation of α, β-unsaturated ketones

[0032] Taking chalcone as an example, its preparation method is:

[0033] Benzaldehyde (1.1018g, 10.3822mmol) and acetophenone (1.2616g, 10.5001mmol) were dissolved in 30mL of ethanol, NaOH aqueous solution (0.8000g, 20.0016mmol dissolved in 30mL of water) was added dropwise at 0°C, and the addition was completed After that, it was stirred at room temperature for 3 hours, filtered, and the solid was recrystallized to obtain 1.7225 g of chalcone, with a yield of 82.7%.

[0034] The following Examples 3-17 were prepared according to the method described in Example 2, wherein different reaction substrates and their feeding amounts, different reaction products and their yields are listed in Table 1.

[0035] Reaction substrate and its charging amount in the embodiment 3~17 of table 1, reaction product and its productive rate

[0036]

[0037]

Embodiment 18

[0038] Embodiment 18: Preparation of compound III-1

[0039] 2-Amino-4-dimethylamino-1,3,5-triazine (0.1399g, 1.0053mmol), chalcone (0.1303g, 0.6257mmol) and chlorobenzene (2mL), iodine (0.3175g, 1.2509mmol) and copper chloride (0.0164g, 0.1220mmol) were added to the reactor, and reflux reaction (135°C) under oxygen conditions for 9h. Cool after the reaction, add 30 mL of 0.4M aqueous sodium thiosulfate solution to neutralize excess iodine, stir for 5 minutes, extract with ethyl acetate (20 mL × 3), combine the organic layers, concentrate, column chromatography (eluent is di Chloromethane:methanol=100:1, v:v), collect R f The eluate with a value of 0.1-0.55 (monitored by TLC, the developing solvent is the same as the eluent), the solvent was distilled off under reduced pressure, and dried to obtain 0.2023 g of the target compound (III-1), with a yield of 94%. 1 H NMR (500MHz, CDCl 3 ):δ=9.90(s,1H),7.47-7.46(m,2H),7.33-7.32(m,2H),7.29-7.25(m,1H),7.16-7.13(m,1H),7.11-7.08 (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com