Perovskite solar cell light absorption layer

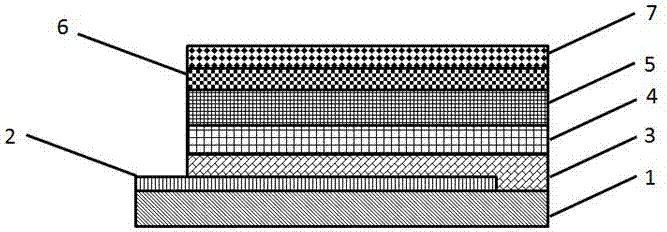

A technology for solar cells and light-absorbing layers, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of insufficient crystallinity of light-absorbing layers of perovskite solar cells, changes in electrical and optical properties of light-absorbing layers, and difficult material preparation processes Control and other issues, to achieve the effect of high photoelectric conversion efficiency, simple preparation method, and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

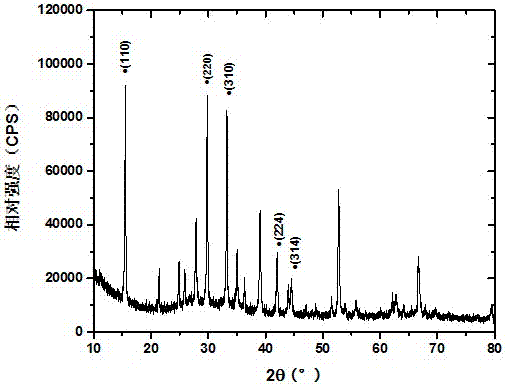

[0029] Terephthalic acid-containing (H 2 Light-absorbing layer of BDC) precursor solution

[0030] a) Clean the FTO glass substrate: ultrasonically clean with acetone, alcohol, and deionized water for 15 minutes respectively, and then blow dry with pure nitrogen;

[0031] b) Immerse the treated substrate in the prepared 0.2M TiCl 4 solution, airtightly placed in a drying oven at 70 °C and heated for 1 h, the substrate was washed with deionized water and ethanol, and then annealed at 100 °C for 1 h to obtain a dense layer;

[0032] c) P25 TiO acidified with acetic acid 2 Powder, ethanol solution containing 10% mass ratio of ethyl cellulose and terpineol are uniformly mixed and dispersed according to the mass ratio of 0.06:3:2; finally, three times the mass of ethanol is added to dilute to prepare a porous layer slurry;

[0033] d) Spin-coating a porous layer of TiO on a transparent conductive substrate prepared with a dense layer by spin-coating method 2 slurry and sintered t...

Embodiment 2

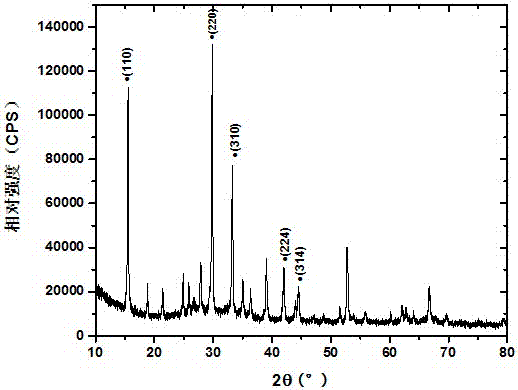

[0039] Preparation of Light Absorbing Layer Containing 2,6-Naphthalene Dicarboxylic Acid (2,6-NDC) Precursor Solution Based on Dense Titanium Dioxide

[0040] a) is the same as step a) of Example 1;

[0041] b) is the same as step b) of Example 1;

[0042] c) Add 0.159 g CH 3 NH 3 I, 0.461 g PbI 2 , 700 μL butyrolactone, 300 μL dimethyl sulfoxide and 10 mg 2,6-naphthalene dicarboxylic acid (2,6-NDC) were mixed to obtain a mixed solution, and the mixed solution was heated and stirred at 70°C for 12 hours, and configured as Perovskite material precursor solution;

[0043] d) On the dense layer obtained in step b), the perovskite material precursor solution of step c) is spin-coated at 4000r / min, and dried at 120°C for 6 minutes to obtain 2,6-naphthalene dicarboxylic acid (2,6- NDC) light-absorbing layer of the precursor solution.

Embodiment 3

[0045] Preparation of light-absorbing layer containing 4,4'-biphenyldicarboxylic acid (BPDC) precursor solution based on transparent conductive film FTO

[0046] a) is the same as step a) of Example 1;

[0047] b) 0.159 g CH 3 NH 3 I, 0.461 g PbI 2 , 700 μL butyrolactone, 300 μL dimethyl sulfoxide, and 5 mg 4,4′-biphenyldicarboxylic acid (BPDC) were mixed to obtain a mixed solution, which was heated and stirred at 70°C for 12 hours to form perovskite Mineral material precursor solution;

[0048] c) On the FTO layer of the transparent conductive film obtained in step a), spin-coat the perovskite material precursor solution in step b) at 4000r / min, and dry it at 120°C for 6 minutes to obtain 4,4′-biphenyl dicarboxylic acid (BPDC) light-absorbing layer of the precursor solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com