Preparation method and application of nano MFe2O4 supported hollow fiber composite ceramic membrane with catalytic separation function

A fiber composite and ceramic membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, water/sludge/sewage treatment, etc., can solve problems such as high energy consumption, single separation function, etc., to improve effluent water quality and reduce membrane Pollution, good anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

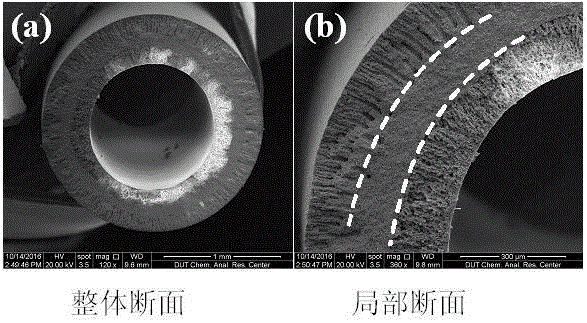

[0039] Example 1: Preparation of composite membrane carrier hollow fiber alumina ceramic membrane

[0040] Load CoFe 2 O 4 The carrier membrane used in the hollow fiber composite ceramic membrane is alumina hollow fiber ceramic membrane. The specific preparation steps are as follows:

[0041] The first step: casting film slurry configuration

[0042] According to the composition of the casting film slurry is α-Al 2 O 3 :PESf: NMP: PVP=50:9.8:39.2:3 (wt%) Weigh the raw materials, the total weight is 200g, and weigh 1.25 times the powder mass of different particle size zirconia pellets, add it to the organic matter, 380 Ball mill uniform organic matter at revolutions / min for 6 hours, then add the ceramic powder in 2-3 batches to the uniformly mixed organic solvent and ball mill for 48 hours to obtain a uniform casting film slurry.

[0043] The second step: treatment of casting film slurry

[0044] Pour the uniformly ball-milled casting film slurry on a 200 mesh gauze to separate the zirc...

Embodiment 2

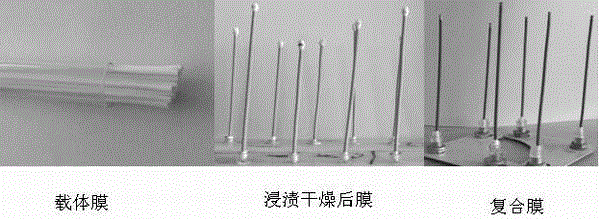

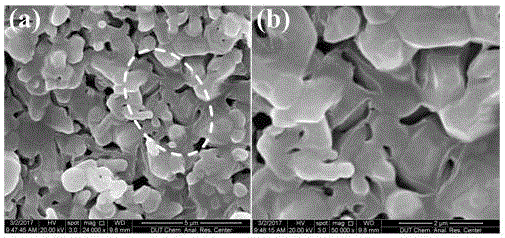

[0050] Example 2: Load CoFe 2 O 4 Of hollow fiber composite ceramic membrane

[0051] Load CoFe 2 O 4 The hollow fiber composite ceramic membrane of the hollow fiber composite ceramic membrane uses hollow fiber alumina as the carrier, and uses the citric acid-stabilized metal nitrate salt solution as the impregnating mother liquor, and is calcined in a low-temperature muffle furnace to phase the catalyst and strengthen the bonding strength with the carrier membrane. The specific steps are as follows:

[0052] Step 1: Preparation of citric acid stabilized metal nitrate catalyst mother liquor

[0053] According to the molar ratio of 1:2:3, weigh 10mmol, 20mmol and 30mmol of cobalt nitrate, ferric nitrate and citric acid, and add the metal salt to a beaker containing 50ml of pure water. Add the citric acid to the same volume of pure water. Place the beaker containing the citric acid solution in the water bath and heat to 60 o C. Add the metal mixed salt solution dropwise to the citric a...

Embodiment 3

[0059] Example 3: Load CoFe under gravity drive 2 O 4 Hollow fiber composite ceramic membrane coupled with SR-AOPS to remove low-concentration methyl blue dye wastewater application

[0060] The steps for removing methyl blue from the composite membrane under gravity drive are as follows:

[0061] The first step: Weigh methyl blue and configure it into an aqueous solution with a concentration of 25mg / L as simulated dye wastewater;

[0062] Step 2: Load the membrane into the gravity-driven membrane module, and let the methyl blue solution act on gravity for 10 minutes to achieve adsorption and desorption equilibrium;

[0063] The third step: Weigh potassium hydrogen persulfate and add it to the methyl blue solution to make the concentration 1.0g / L, the pH of the solution is not adjusted, and replace the composite membrane contact solution with the target concentration of methyl blue and persulfuric acid Hydrogen potassium mixed solution, carry out experiments at different water levels;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com