Preparation of charcoal-based material and application thereof in removing typical organic chloride pesticide in water environment

A base material, biochar technology, applied in the direction of water pollutants, other chemical processes, water/sewage treatment, etc., can solve the problems of high economic cost, low efficiency, limited use, etc., to achieve large specific surface area, loose texture, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of biochar-based material in this embodiment is as follows:

[0047] 1. Pretreatment: After obtaining the wetland plant canna from the wild, wash the root soil with deionized water, cut the plant into pieces (less than 5cm), place it in a ventilated place for two days, and then dry it at a temperature of 354K to constant weight;

[0048] 2. Removal of long fibers: crush the pretreated wetland plants to 100-300 mesh through a plant crusher, mix them evenly and pass through a 200-mesh sieve to obtain biomass materials;

[0049] 3. Preparation of biochar-based materials by oxygen-limited heating method: put the biomass material obtained in step 2 into a corundum container, put it into a tube furnace, and pass in nitrogen, the flow rate is controlled at 300mL / min, and it is obtained by oxygen-limited heating method Biochar-based material CANB550 (canna biochar). The obtained biochar-based material was lowered to room temperature and placed in a brown jar, s...

Embodiment 2

[0053] The preparation of biochar-based material in this embodiment is as follows:

[0054] 1. Pretreatment: After obtaining the wetland plant calamus from the wild, wash the root soil with deionized water, cut the plant into pieces (less than 5cm), place it in a ventilated place for two days, and then dry it at a temperature of 354K to constant weight;

[0055] 2. Removal of long fibers: crush the pretreated wetland plants to 100-300 mesh through a plant crusher, mix them evenly and pass through a 200-mesh sieve to obtain biomass materials;

[0056] 3. Preparation of biochar-based materials by oxygen-limited heating method: put the biomass material obtained in step 2 into a corundum container, put it into a tube furnace, and pass in nitrogen, the flow rate is controlled at 300mL / min, and it is obtained by oxygen-limited heating method Biochar-based material CALB550 (calamus biochar). The obtained biochar-based material was lowered to room temperature and placed in a brown ja...

Embodiment 3

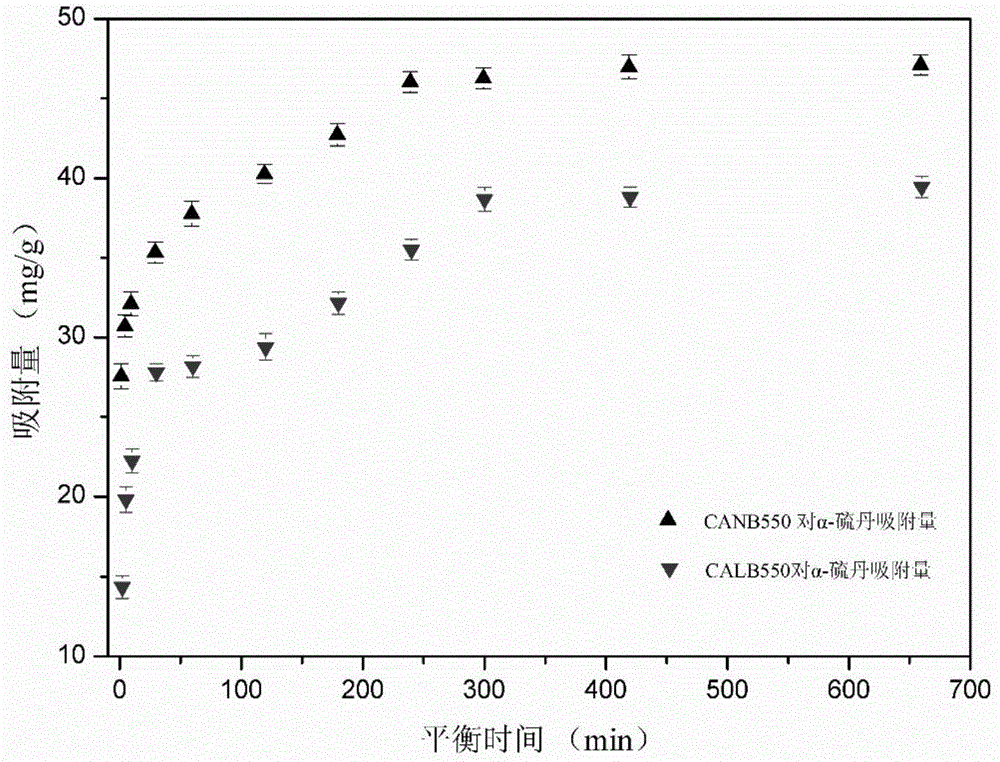

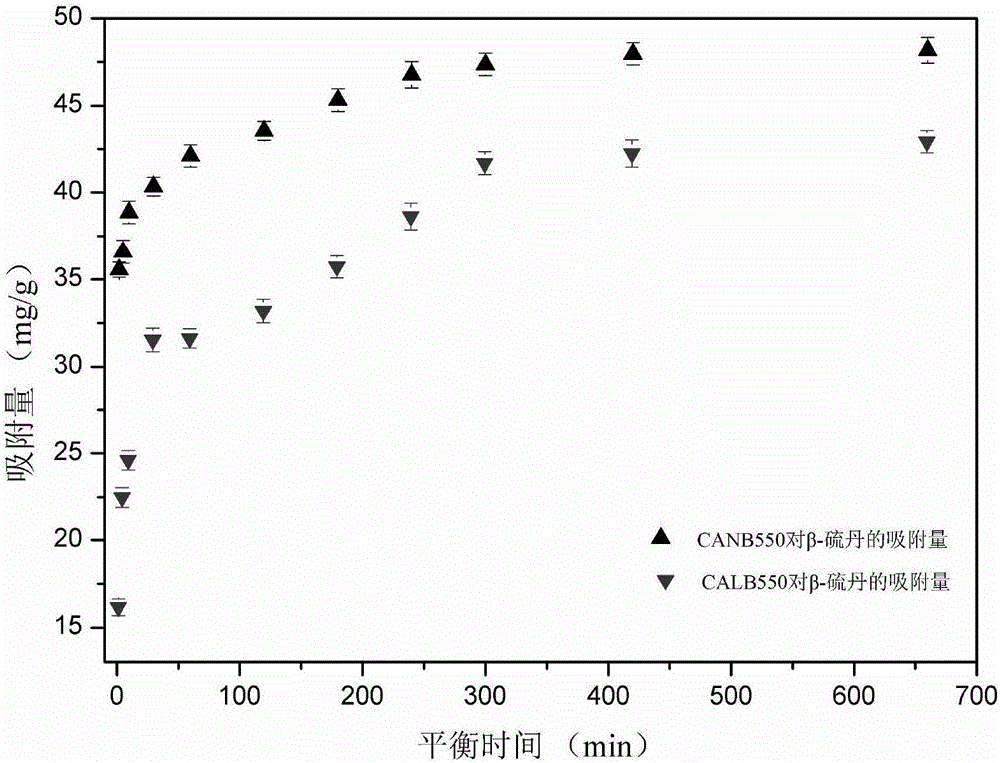

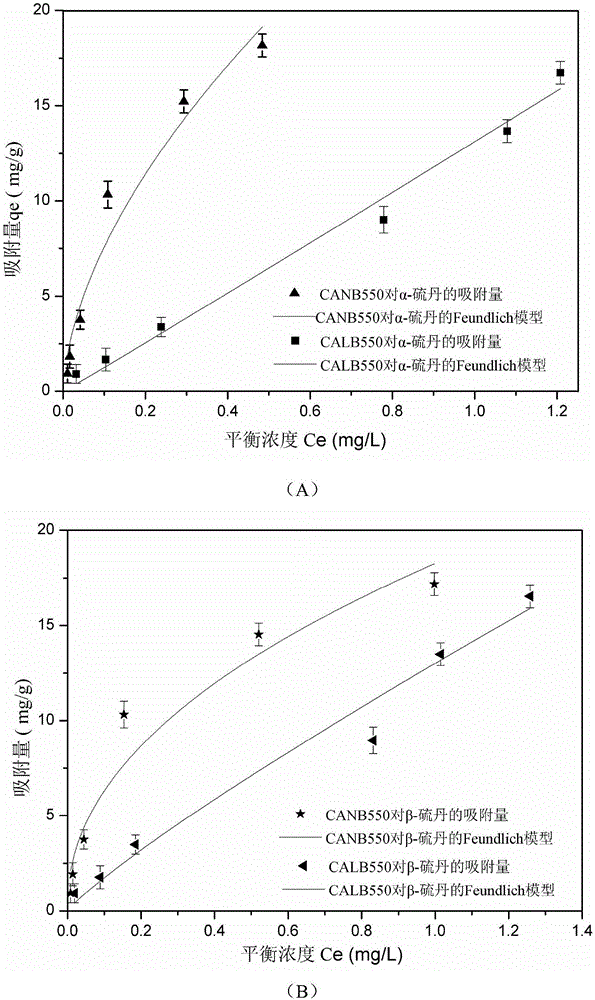

[0060] Take by weighing 50mg CANB550 and 50mg CALB550, add respectively in the Erlenmeyer flask with stopper that contains 100mL endosulfan mixed solution, the concentration of α-endosulfan and β-endosulfan in the endosulfan mixed solution is set as a series of concentration gradients, respectively 0.5, 1, 2, 5.36, 8, 10mg / L, the pH value is about 5.6 (the pH of deionized water), the Erlenmeyer flask is placed in a constant temperature shaker for 7h (room temperature, 150rpm), the results are as follows figure 2 with image 3 shown. The adsorption rates of CANB550 to 0.5mg / L α-endosulfan and β-endosulfan reached above 94.8% and 90.0% respectively, and the adsorption rates of CALB550 to α-endosulfan and β-endosulfan reached above 86.4% and 84.6% respectively. For CANB550 and CALB550, the adsorption rate of α-endosulfan is higher, compared with β-endosulfan, the logK of α-endosulfan ow (4.94) is higher, the hydrophobic effect is more significant, and the adsorption capacity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com