Graphene and preparation method thereof

A graphene and substrate technology, applied in the field of graphene preparation, can solve the problems of high cost and large gas consumption, and achieve the effects of smooth surface, low preparation cost and low gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

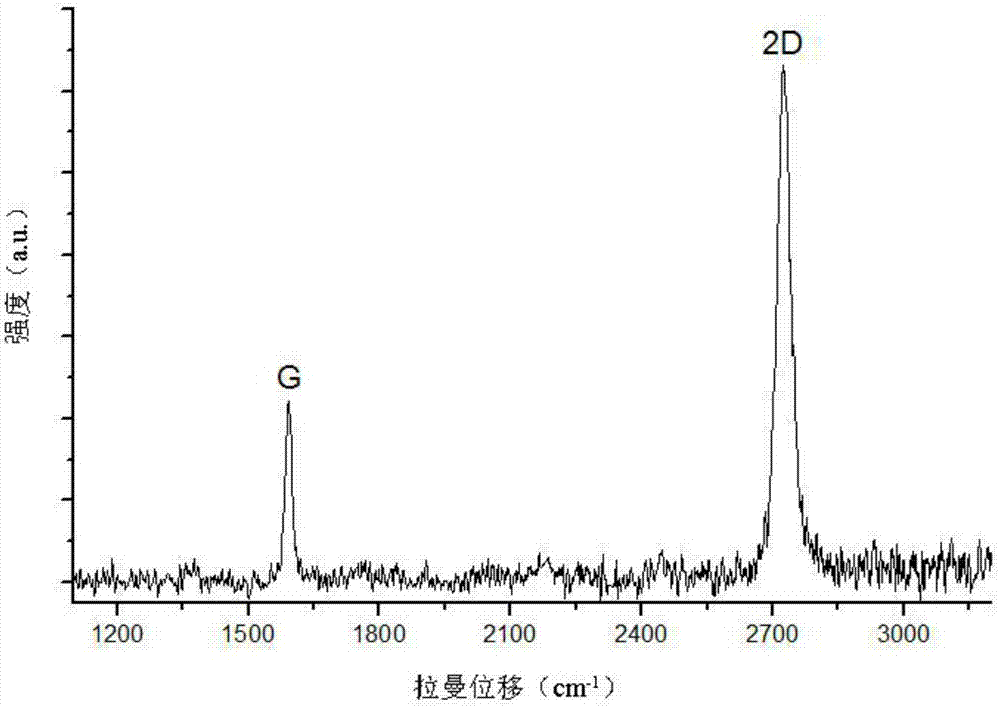

[0060] The 25 μm thick double-sided polished rolled copper foil pretreated by 2mol / L ammonium persulfate solution was rinsed with deionized water, anhydrous isopropanol, and anhydrous ethanol in sequence, dried with nitrogen, and then placed in a CVD furnace for growth. First use methane and hydrogen 50sccm to purge the furnace chamber respectively, then close the gas, vacuum the furnace chamber to below 1Pa, feed 50sccm hydrogen gas, and maintain the pressure at 36Pa; within 25 minutes, the surface temperature of the copper foil is raised to 700°C, and the temperature was raised to 1000°C over 40 minutes. Turn off the hydrogen, anneal at a high temperature and constant temperature for 30 minutes, and then pass in methane and hydrogen at the same time. The feed flow rate of methane was adjusted to be 7 sccm, and the hydrogen gas was 50 sccm for 30 minutes, and the pressure in the quartz tube was kept at 100 Pa. Then turn on the external fan and water cooling, and when the fur...

Embodiment 2

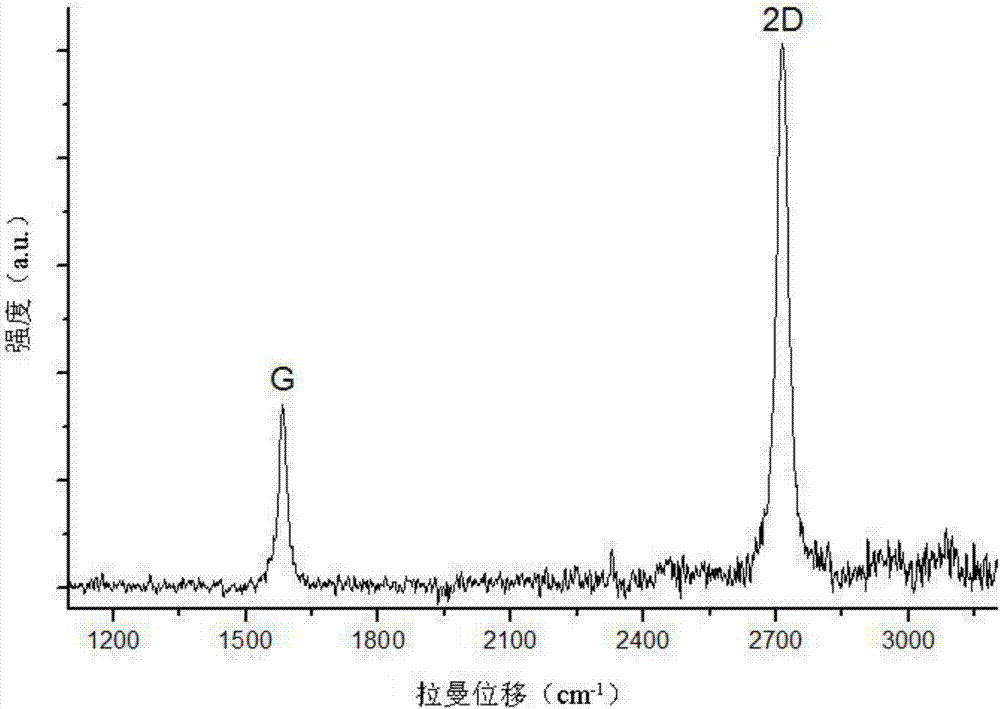

[0063] The 25 μm thick double-sided polished rolled copper foil pretreated by 1mol / L ferric chloride solution was rinsed with deionized water, anhydrous isopropanol, and anhydrous ethanol in sequence, dried with nitrogen, and then placed in a CVD furnace for growth. First use methane and hydrogen 50sccm to purge the furnace cavity respectively, then close the gas, vacuumize the furnace cavity to below 1Pa, feed 40sccm hydrogen, and maintain the pressure at 32Pa; within 65 minutes, the surface temperature of the copper foil is raised to 1000°C. Turn off the hydrogen, anneal at a high temperature and constant temperature for 15 minutes, and then pass in methane and hydrogen at the same time. The flow rate of methane was adjusted to be 7 sccm, and the hydrogen gas was 20 sccm for 20 minutes, and the pressure in the quartz tube was kept at 60 Pa. Then turn off the methane and hydrogen, turn on the external fan and water cooling, and cool the substrate to room temperature at a coo...

Embodiment 3

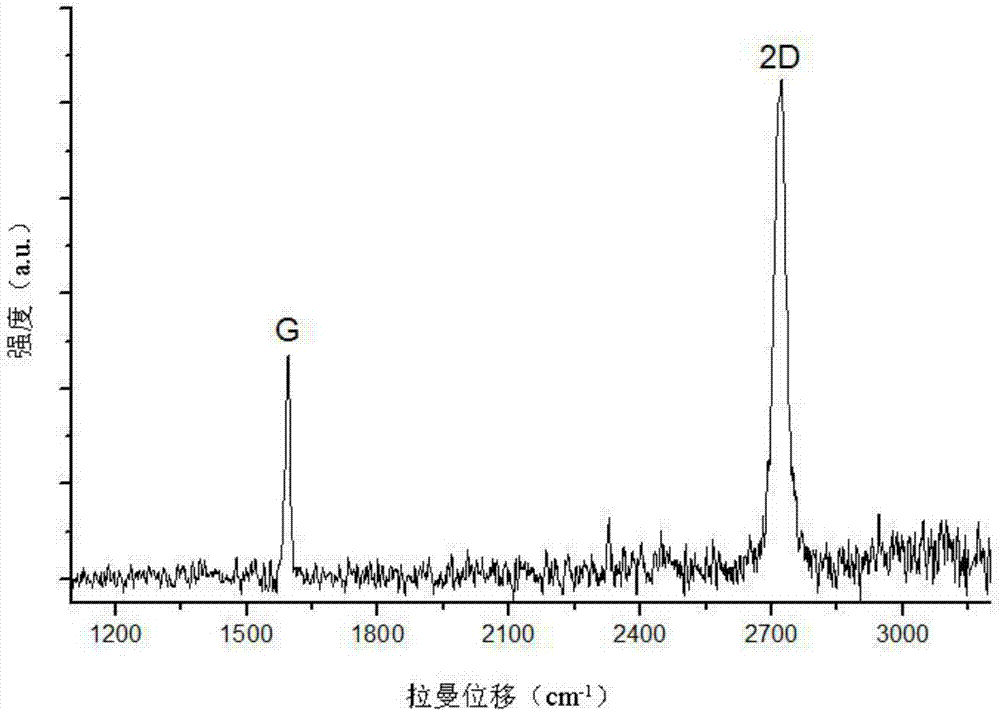

[0066] The 25 μm thick double-sided polished rolled copper foil pretreated with 1mol / L acetone was rinsed with deionized water, anhydrous isopropanol, and anhydrous ethanol in sequence, dried with nitrogen, and placed in a CVD furnace for growth. First use methane and hydrogen 50sccm to purge the furnace chamber respectively, then close the gas, vacuum the furnace chamber to below 1Pa, feed 60sccm hydrogen gas, and maintain the pressure at 40Pa; within 30 minutes, the surface temperature of the copper foil is raised to 800°C, and the temperature was raised to 1000°C over 40 minutes. Turn off the hydrogen, anneal at a high temperature and constant temperature for 20 minutes, and then pass in methane and hydrogen at the same time. The feed flow rate of methane was adjusted to be 5 sccm, and the hydrogen gas was 50 sccm for 40 minutes, and the pressure inside the quartz tube was kept at 120 Pa. Then turn off the methane and hydrogen, turn on the external fan and water cooling, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com