A kind of preparation method of alginic acid-dopamine/nano hydroxyapatite composite scaffold

A nano-hydroxyapatite and hydroxyapatite technology, which is applied in the fields of polymer materials and biological materials, can solve the problems that the compatibility of human body is not very ideal, achieve suitable porosity, promote tissue regeneration, and achieve good dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

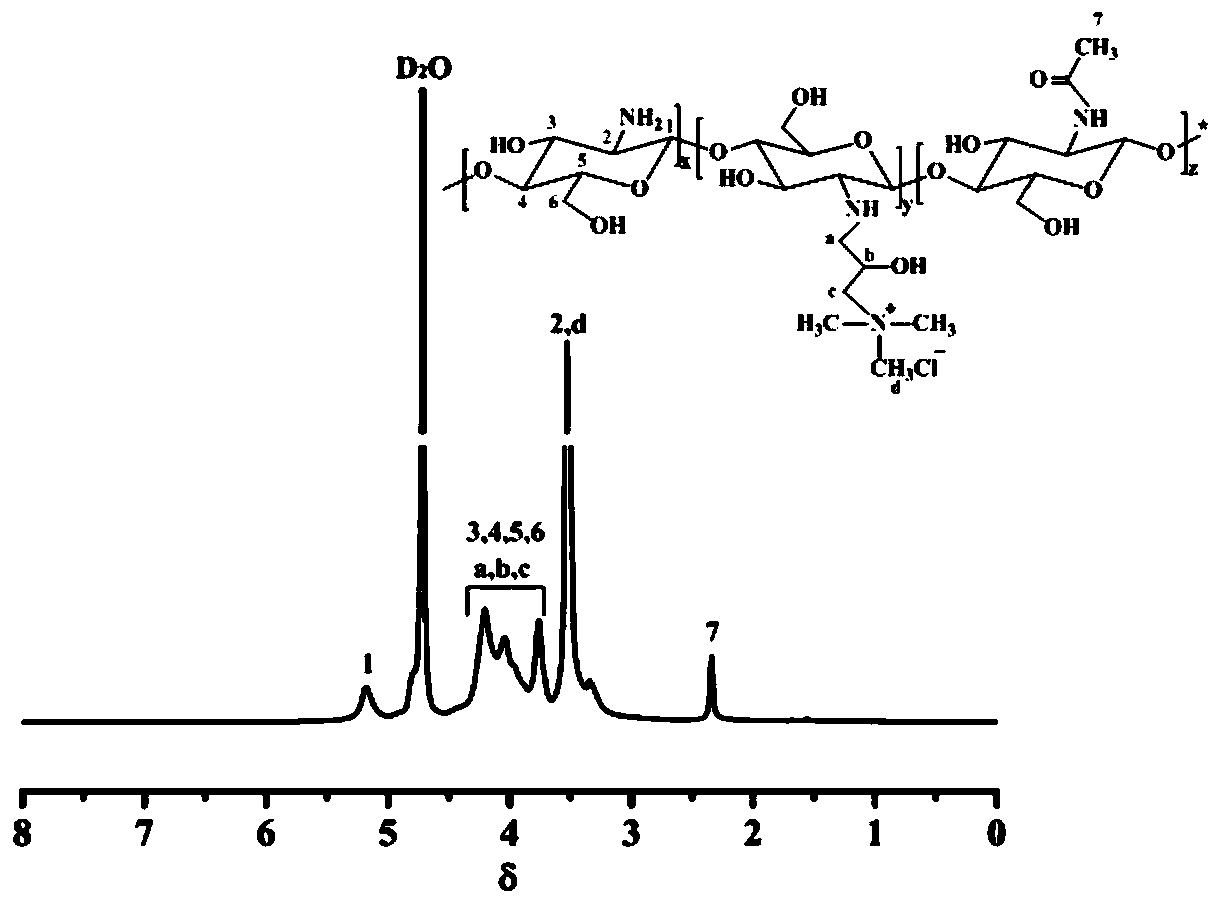

[0015] Example 1. Synthesis of quaternized chitosan (QCS)

[0016] 4g of chitosan (CS) was dispersed in 100mL of KOH-LiOH.H2O-urea-H2O mixed solution with a mass ratio of 7:8:8:77 to obtain the CS dispersion, which was placed in a refrigerator at -20°C overnight. Then thaw at 5°C and stir until a transparent CS solution is obtained. Then 62.3 mL of (3-chloro-2-hydroxypropyl) trimethylammonium chloride solution (CHPTAC) was added dropwise to the CS solution, and the reaction was stirred at 30° C. for 24 h. After the reaction, the solution was neutralized with hydrochloric acid, and lyophilized after being dialyzed in deionized water for a week. The white flocculent sample obtained was quaternized chitosan (QCS) with a quaternization degree of 96.8%.

[0017] It should be noted that by changing the addition amount of CHPTAC in Example 1 to 7.78, 15.6, and 31.1 mL, quaternized chitosan (QCS) with quaternization degrees of 17.7, 23.3, and 47.2% can be obtained, respectively.

Embodiment 2

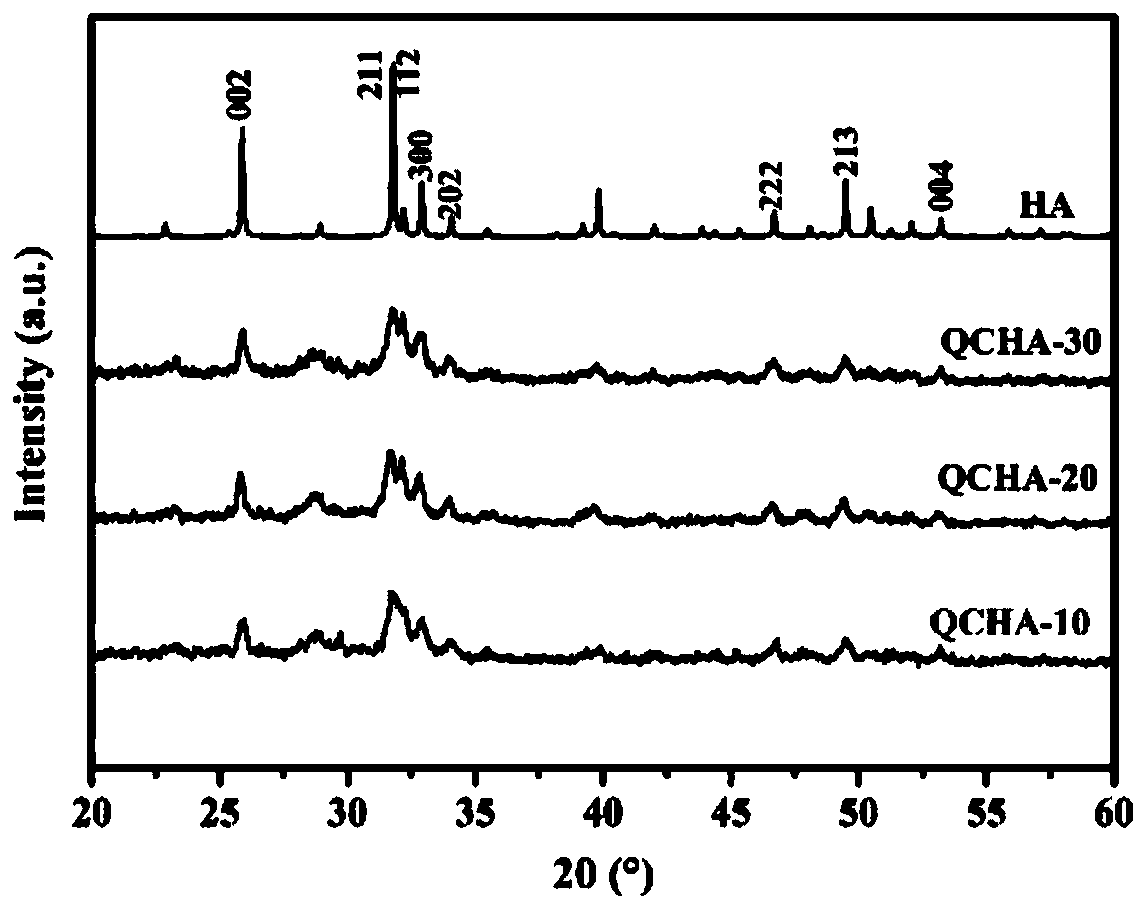

[0018] Example 2: Synthesis of quaternized chitosan / hydroxyapatite (QCHA)

[0019] Dissolve a certain amount of QCS in 0.3M Na 2 HPO 4 In the solution, stir at room temperature for 1h; then heat to 90℃, under the condition of mechanical stirring, add a certain amount of 0.5M CaCl with the atomic ratio of Ca / P of 1.67 2 The solution was added to the above QCS solution at 2 mL / min. In this process, 1M NaOH was used to adjust the pH of the reaction solution to about 10. After 2 hours of reaction, a white precipitate was obtained by centrifugation, and the precipitate was washed with deionized water until the pH value was close to neutral, and then lyophilized to obtain QCHA. The theoretical ratio of quaternized chitosan to hydroxyapatite is 3:7, and the corresponding QCHA label is QCHA-30.

[0020] It should be noted that by changing the theoretical ratio of quaternized chitosan to hydroxyapatite in Example 2 to 1:9 and 2:8, QCHA-10 and QCHA-20 can be obtained respectively.

Embodiment 3

[0021] Example 3. Preparation of alginic acid-dopamine

[0022] Weigh 1g of alginic acid (Alg), put it into a three-necked flask, add 100mL PBS buffer (50mM, pH=5.5.), stir to dissolve at room temperature, when it is completely dissolved, add 1.94g 1-ethyl-(3- Dimethylaminopropyl) carbodiimide hydrochloride (EDC) and 2.32g N-hydroxysuccinimide (NHS), n(COOH) / n(EDC) / n(NHS)=1 / 2 / 4, after activation at room temperature for 30 minutes, add 4.79g of dopamine hydrochloride (DA), repeatedly vacuum and pass nitrogen three times to remove air and prevent DA oxidation, react at room temperature under a nitrogen atmosphere for 24 hours, stop the reaction and dialyze in deionized water After removing EDC, NHS and unreacted monomers, until there is no dopamine ultraviolet absorption peak in the dialysate, freeze-drying to obtain a white cotton-like bio-modified macromolecule Alg-DA with a DA substitution degree of 52.6%.

[0023] It should be noted that by changing the amount of DA added in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com