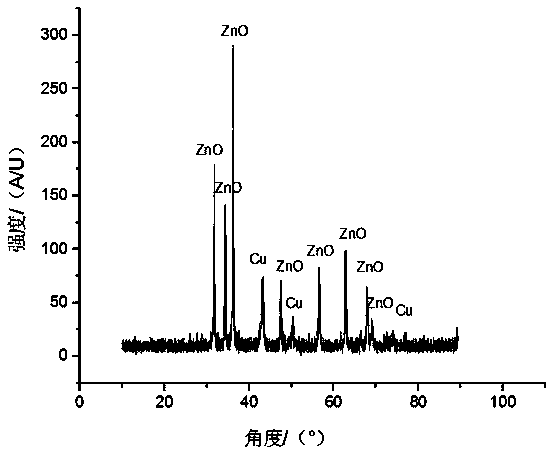

A kind of preparation method of cu/zno photocatalyst

A photocatalyst and mineralizer technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor dispersion, difficult recovery, weak visible light region, etc., and achieve photocatalysis The effect is good, the process is simple and general, and the reaction time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of a kind of Cu / ZnO photocatalyst of the present embodiment, concrete steps are as follows:

[0027] (1) First, mix zinc powder and copper powder with a mass ratio of 1:1 to obtain a copper-zinc mixture. The particle size of zinc powder and copper powder is 40 mesh, and the purity is above 99.9%. Pour the copper-zinc mixed raw material into a vacuum In the smelting furnace of the induction atomization powder making furnace, the temperature is 1100 °C, the diameter of the guide tube of the vacuum induction atomization powder making furnace is 2.5mm, and the atomization is carried out with argon gas at an atomization pressure of 3MPa to obtain spherical Zn -Cu alloy powder with a particle size of about 15 μm;

[0028] (2) According to step (1) the mass volume ratio of Zn-Cu alloy powder and mineralizer is 1: 20g / mL ratio, the Zn-Cu alloy powder obtained in step (1) is added to mineralizer Among them, the mineralizer is a tetramethylammonium bicarbo...

Embodiment 2

[0033] The preparation method of a kind of Cu / ZnO photocatalyst of the present embodiment, concrete steps are as follows:

[0034] (1) First, mix zinc powder and copper powder with a mass ratio of 8:5 to obtain a copper-zinc mixture. The particle size of the zinc powder and copper powder is 40 mesh, and the purity is above 99.9%. Pour the copper-zinc mixed raw material into a vacuum In the smelting furnace of the induction atomization powder making furnace, the temperature is 900 ° C, the diameter of the guide tube of the vacuum induction atomization powder making furnace is 2.5 mm, and the atomization is carried out with nitrogen at an atomization pressure of 3 MPa, and spherical Zn can be obtained. -Cu alloy powder, the particle size is about 14μm;

[0035] (2) According to step (1) the mass volume ratio of Zn-Cu alloy powder and mineralizer is 1: 30g / mL, the Zn-Cu alloy powder obtained in step (1) is added to the mineralizer Among them, the mineralizer is a solution of tet...

Embodiment 3

[0040] The preparation method of a kind of Cu / ZnO photocatalyst of the present embodiment, concrete steps are as follows:

[0041] (1) First, mix zinc powder and copper powder with a mass ratio of 21:4 to obtain a copper-zinc mixture. The particle size of zinc powder and copper powder is 40 mesh, and the purity is above 99.9%. Pour the copper-zinc mixed raw material into a vacuum In the smelting furnace of the induction atomization powder making furnace, the temperature is 900°C, the diameter of the guide tube of the vacuum induction atomization powder making furnace is 5mm, and nitrogen is used to atomize at an atomization pressure of 4.3MPa to obtain spherical Zn -Cu alloy powder, the particle size is about 14μm;

[0042] (2) According to step (1) the mass volume ratio of Zn-Cu alloy powder and mineralizer is 1: 25g / mL, the Zn-Cu alloy powder obtained in step (1) is added to the mineralizer Among them, the mineralizer is a tetramethylammonium bicarbonate solution with a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com