Micron-sized porous tungsten and preparation method thereof

A porous tungsten, micron-scale technology, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as low production efficiency, high sintering temperature, low porosity, etc., and achieve high automation level, simple process equipment, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

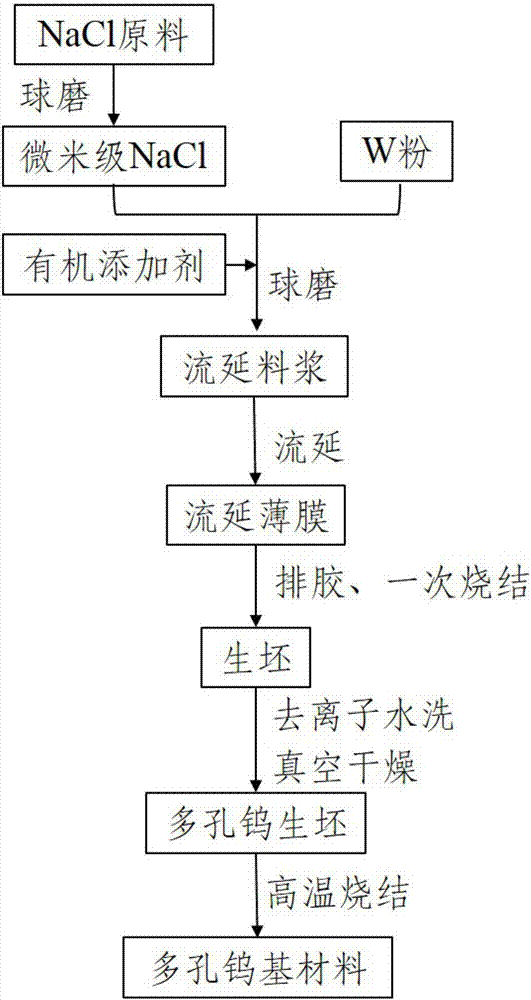

[0034] A method for preparing micron-scale porous tungsten, comprising the following steps:

[0035] 1) The raw materials NaCl, ethanol and ball milling medium are ball milled, and then vacuum dried at 60° C. for 12 hours to obtain NaCl powder;

[0036] 2) Raw material preparation: 50-60% of tungsten powder, 0%-8.5% of NaCl powder, 32.6-38.4% of organic solvent and 5.3-7.4% of organic additives are prepared according to the mass percentage, wherein organic additives include 2.5%-3.5% % of polyvinyl butyral, 0.8%-1.2% of Hypermer KD-1 and 2.0%-2.7% of glycerin;

[0037] 3) Preparation of casting slurry: adding NaCl powder, tungsten powder and organic additives into an organic solvent for ball milling to obtain casting slurry;

[0038] 4) Processing of the cast ribbon: cast the cast slurry obtained in step 3) in the cast machine to dry and set the shape to obtain the cast ribbon, cut the cast ribbon into a specific shape, and cut the cast ribbon into a specific shape, and cut t...

Embodiment 1

[0041] This embodiment provides a method for preparing micron-scale porous tungsten, including the following steps:

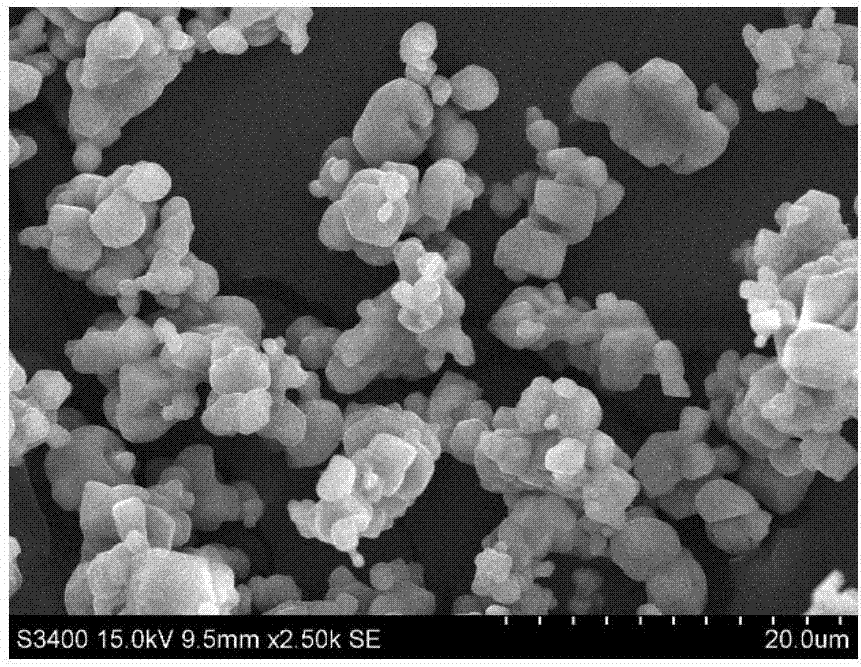

[0042]A. Preparation of casting slurry: 100g NaCl and 50g ethanol were added into a nylon tank, and ball milled in a planetary ball mill for 36 hours, wherein the NaCl raw material had a purity of 99.9%, passed through a 60-mesh sieve, and the ball milling speed was 250rpm. Pour the obtained suspension into a beaker, let it stand at room temperature in a vacuum drying oven for 1 hour, pour out the upper liquid, and vacuum-dry the remaining material in the beaker at 60°C for 12 hours in a vacuum oven, and take 2.4g of NaCl powder and 56g of particle size 5μm W powder, 0.9g of Hypermer KD-1 (analytical pure), add 18.3g of absolute ethanol (analytical pure) and 18.3g of methyl ethyl ketone (analytical pure) solvent, ball mill in a high energy mixer for 3h , the ball milling medium is a stainless steel ball, and the mass of the steel ball is 100g. Then 2.6 g of po...

Embodiment 2

[0047] This embodiment provides a method for preparing micron-scale porous tungsten, including the following steps:

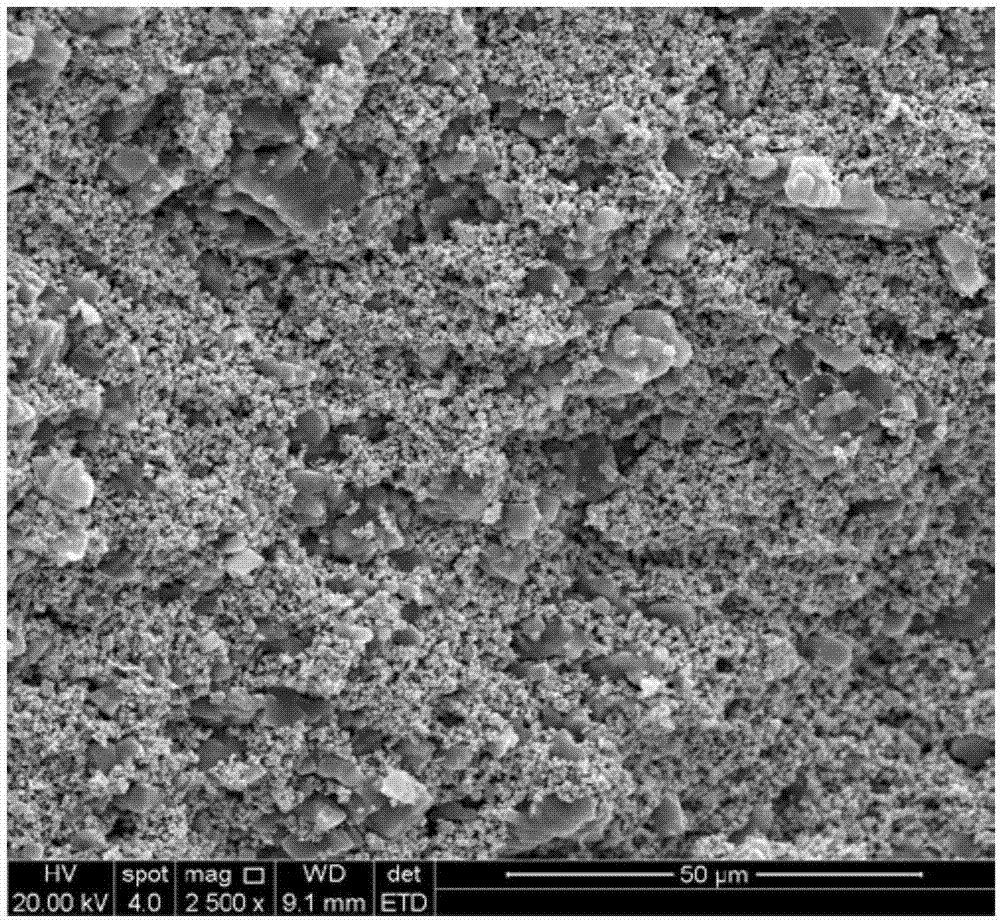

[0048] A. The preparation of casting slurry: get 60g particle diameter and be the W powder of 0.5 μm, the Hypermer KD-1 (analytical pure) of 1.2g, add the dehydrated alcohol (analytical pure) of 16.3g and the butanone of 16.3g ( Analytical pure) solvent, ball milled in a high-energy mixer for 3 hours, then added 3.5 g of polyvinyl butyral (analytical pure), 2.7 g of glycerin (analytical pure), and ball milled for 3 hours to obtain casting slurry.

[0049] B. The processing of casting ribbon: the casting slurry obtained in step A is cast and dried in a casting machine to obtain a casting ribbon, and the casting ribbon is cut into a disc with a diameter of 20mm. 100-layer die stack. The vacuum degree of the laminated strip is better than 9.9×10 -3 In the environment of Pa, heat treatment at 780°C for 2h for debinding; followed by a sintering to obtain a green b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com