Copper sulfide ore flotation collector and preparation method and application thereof

A technology of copper sulfide ore and collector, applied in the field of metallurgy, can solve the problems of high pH and high reaction temperature, and achieve the effects of high yield, good selectivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

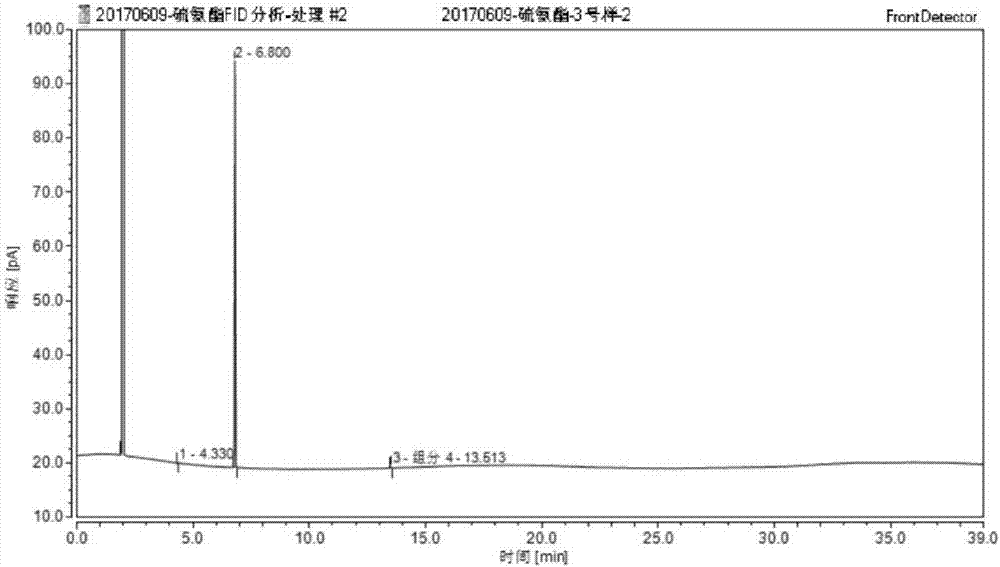

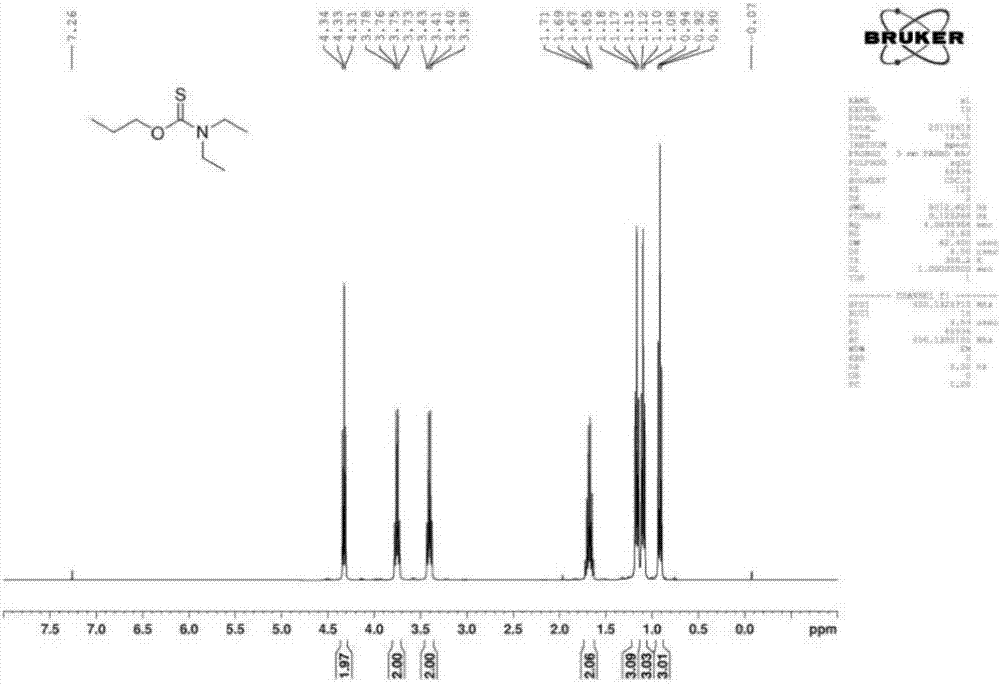

[0038] Example 1 Synthesis of O-propyl-N,N-diethylthiocarbamate

[0039]

[0040] Add 15.80g (0.10mol) sodium n-propyl xanthate and 11.60g (0.10mol) sodium chloroacetate to a 250ml three-necked round bottom flask containing 100.0mL distilled water, and add 4mol / L NaOH solution dropwise to adjust the reaction solution pH=8.0, stirring at 30°C for 2 hours. While stirring, 7.30 g (0.10 mol) of diethylamine was slowly added dropwise, and the mixture was reacted at 30° C. for 3 hours. After the reaction is finished, the turbid liquid is left to stand for stratification, and the oily liquid of the upper layer is the target product, and 8.7g of product is obtained by separation, and the yield is 49.71%. Figure 1a shown. from Figure 1b It can be seen that the NMR data are as follows: 1 HNMRδ: 0.91(t, 3H, CH 2 CH 3 ),1.10(t,3H,CH 2 CH 3 ),1.15(d,3H,CHCH 3 ),1.7(d,2H,CH 2 CH 3 ),3.40(q,2H,NCH 2 CH 3 ),3.75(q,2H,NCH 2 CH 3 ),4.35(m,2H,OCH 2 CH 3 )ppm.

Embodiment 2

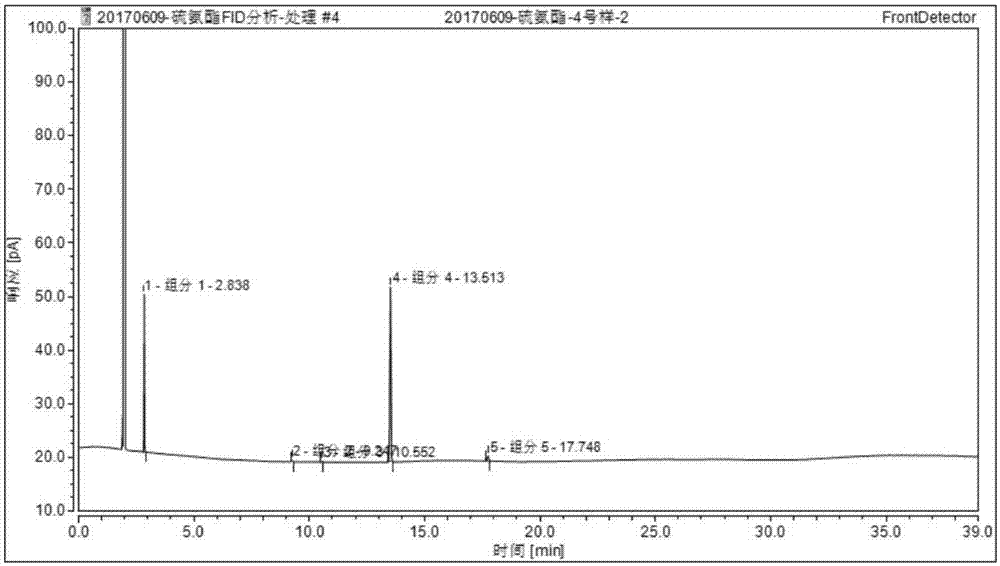

[0041] Example 2 Synthesis of O-propyl-N,N-dibutylthiocarbamate

[0042]

[0043] Add 15.80g (0.10mol) sodium n-propyl xanthate and 11.60g (0.10mol) sodium chloroacetate to a 250ml three-necked round bottom flask containing 100.0mL distilled water, and add 4mol / L NaOH solution dropwise to adjust the reaction solution pH=8.0, stirring at 30°C for 2 hours. While stirring, 12.50 g (0.10 mol) of di-n-butylamine was slowly added dropwise, and the reaction was carried out at 30° C. for 3 hours. After the reaction, the turbid liquid was left to stand for stratification, and the oily liquid of the upper layer was the target product, and 20.10 g of product were obtained by separation, and the yield was 87.00%. The content of the product was 69.67% by gas chromatography (GC), specifically as Figure 2a shown. from Figure 2b It can be seen that the NMR data are as follows: 1 H NMRδ: 0.93 (9H, CH 2 CH 3 ),1.30(4H,CH 2CH 3 ),1.65(2H,CH 2 CH 3 ),1.71(4H,CH 2 CH 3 ),3.40(q,2H...

Embodiment 3

[0044] Example 3 Study on flotation performance of thiourethane collector

[0045] The specific flotation process is as follows: image 3 As shown, under the condition of natural pH, after stirring for 2min, add a regulator (such as sodium hydroxide) for 1min, add a collector and stir for 2min, flotation for 2min, the concentration of the collector is 5-10mg / L, and flotation obtains a foam product.

[0046] When the concentration of two collectors of compounds Ia and Ib is 10 mg / L and pH=9, the flotation recovery rate of Ia collector to chalcopyrite is 75.53%, and the flotation recovery rate to pyrite is 15.09%, The copper-sulfur flotation separation effect is better. The flotation recovery rate of Ib collector to chalcopyrite was 66.83%, and the flotation recovery rate to pyrite was 36.72%.

[0047] The collectors shown in Examples 1 to 2 of the present invention have better flotation activity for chalcopyrite and pyrite, and the collecting capacity for chalcopyrite is bett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com