Organic-inorganic composite bentonite material and preparation method and application thereof

An inorganic composite and bentonite technology, applied in the direction of inorganic chemistry, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of large-scale popularization and application limitations, high cost of modification, environmental impact, etc., and achieve good adaptability and versatility , low reagent cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a kind of organic-inorganic composite bentonite material, the preparation process of this material is:

[0039] (1) Drop deionized water into 25wt% tetramethylammonium hydroxide solution at a stirring speed of 400rpm so that its concentration becomes 10wt%, and add the amount of orthosilicon etc. to it at a speed of 4mL / min. After the addition of ethyl acetate, stir at room temperature for 24 hours, then continue to stir in a water bath at 60°C for 10 hours, then concentrate it by rotary evaporation, place it in a refrigerator at 2°C for 12 hours, wash and filter the precipitated crystals with acetone , to obtain octapolytetramethylammonium cage silsesquioxane, namely POSS material;

[0040] (2) the bentonite of 10kg is added a certain amount of water to swell, and the bentonite suspension that is mixed with mass percentage concentration is 10wt%;

[0041] (3) Under the condition of stirring at 60° C., 3 wt % tetrabutylammonium bromide solution...

Embodiment 2

[0044] This embodiment provides a kind of organic-inorganic composite bentonite material, the preparation process of this material is:

[0045] (1) prepare POSS material by the step (1) of embodiment 1;

[0046] (2) prepare bentonite suspension by the step (2) of embodiment 1;

[0047] (3) Under the condition of stirring at 60° C., 1 wt % tetrabutylammonium bromide solution and 1 wt % POSS material solution were added dropwise thereto at a solid-to-liquid ratio of 1:10, and stirred for 2 hours. After filtering and drying, the organic-inorganic composite bentonite material sample (referred to as PTB-2) can be obtained.

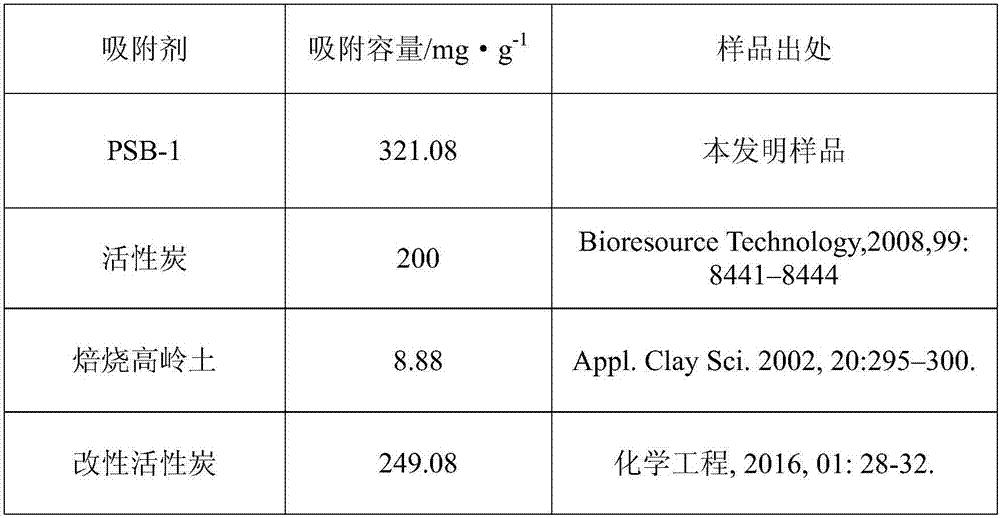

[0048] The interlayer distance was determined by XRD Use 10.0g sample to adsorb methylene blue in 1L 1000ppm methylene blue aqueous solution, and after centrifugation after adsorption for 1h, measure the concentration of methylene blue aqueous solution in water, the result shows that the adsorption rate is 93.6%. Under the same experimental conditions, the ...

Embodiment 3

[0050] This embodiment provides a kind of organic-inorganic composite bentonite material, the preparation process of this material is:

[0051] (1) prepare POSS material by the step (1) of embodiment 1;

[0052] (2) prepare bentonite suspension by the step (2) of embodiment 1;

[0053] (3) Under stirring condition at 90 DEG C, dropwise add 3wt% hexadecyldimethylbenzyl ammonium chloride solution and 5wt% POSS material solution in the ratio of 1:10 by solid-liquid ratio, stir 6 Hour. After filtering and drying, the organic-inorganic composite bentonite material sample (referred to as PHB-1) can be obtained.

[0054] The interlayer distance was determined by XRD According to the measurement results of nitrogen physical adsorption and desorption instrument, it can be seen that the specific surface area A=10.26m 2 / g, pore volume V=0.0703cm 3 / g. Analysis of its thermal stability found that compared with the original soil, the maximum endothermic peak of surface hydroxyl col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com