A system and method for ammonia-based flue gas desulfurization

A desulfurization system and flue gas technology, applied in the field of ammonia flue gas desulfurization system, can solve the problems of preventing crystal growth and continuous growth, easily blocking filters, polluting crystal surfaces, etc., and achieves the effect of improving product quality and production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

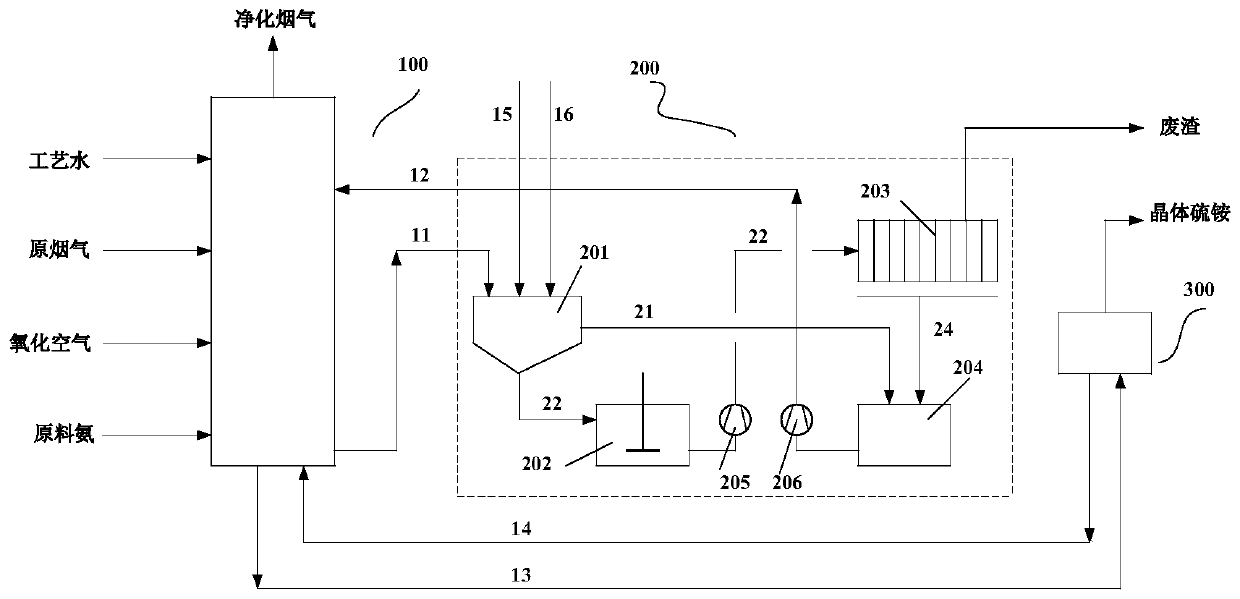

[0027] There are two 260T / hr steam boilers in a certain factory, and the total flue gas emission is 660,000 Nm 3 / hr, SO 2 The content is 2000mg / Nm 3 , the dust content is 50mg / Nm 3 , temperature 140°C, applications such as figure 1 The ammonia-based flue gas desulfurization system shown includes a desulfurization device 100, a slurry dust removal device 200 and an ammonium sulfate extraction device 300. The desulfurization device 100 and the slurry dust removal device 200 form a dust removal circuit through a dusty slurry delivery pipeline 11 and a clear liquid return pipeline 12. The desulfurization device 100 and the ammonium sulfate extraction device 300 form an ammonium sulfate extraction loop through the ammonium sulfate slurry delivery pipeline 13 and the mother liquor return pipeline 14 . Wherein, the slurry dedusting device 200 comprises a settling tank 201, a filter 203 and a clear liquid tank 204, and the desulfurization device 100 is connected to the inlet of th...

Embodiment 2

[0037] The conditions of the flue gas are the same as those in the examples, and the flue gas is treated by using an ammonia-based flue gas desulfurization system and method provided by the present invention. The difference from Embodiment 1 is that in this example, the ammonia replenishment pipeline 15 and the water replenishment pipeline 16 are both connected to the dusty slurry delivery pipeline 11 in order to facilitate pipeline layout and equipment processing.

Embodiment 3

[0039] A power plant has a 600MW coal-fired unit with a flue gas flow rate of 2 million Nm 3 / hr, flue gas SO 2 The content is 12000mg / Nm 3 , the dust content is 30mg / Nm 3 , temperature 125°C, applications such as figure 1 An ammonia-based flue gas desulfurization system is shown to treat flue gas. Different from embodiment 1, take the following steps:

[0040] (1) Flue gas desulfurization: the raw flue gas is sent to the desulfurization device 100, successively passes through the concentration spray layer and the absorption spray layer, reacts with the added raw material ammonia and process water to obtain sulfite ammonium, and oxidizes with the added oxidizing air The ammonium sulfate aqueous solution is reacted in the pool, and the ammonium sulfate aqueous solution enters the concentrated crystallization section, and the ammonium sulfate slurry containing ammonium sulfate crystals is obtained in the ammonium sulfate crystallization pool. At the same time, impurities in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com