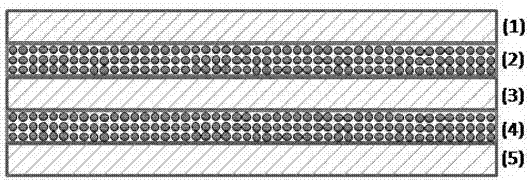

Preparation method of porous catalytic carbon membrane adopting laminated structure

A technology of laminated structure and carbon film, which is applied in the direction of carbon monoxide reaction preparation, chemical instruments and methods, catalysts, etc., can solve the problems of reduced mechanical strength of catalytic carbon film and difficult control of the preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a porous catalytic carbon membrane with a laminated structure, characterized in that: the method comprises the following steps;

[0024] (1) Raw material pretreatment steps:

[0025] Raw material pretreatment of the catalyst layer: Grinding the powdered catalyst, or mixing the powdered catalyst with a binder to form a paste, or grinding the powdered catalyst and mixing it with water to form a paste;

[0026] Raw material pretreatment of the carbon film precursor layer: after mixing the powdery carbon-containing precursor, or powdery carbon-containing precursor and additives, one or more of crushing, grinding, stirring, and then mixing with water to form a slurry Paste;

[0027] (2) Catalyst layer and carbon film precursor layer stacking and compounding step: put the pretreated catalyst layer raw material or the pretreated slime-like carbon film precursor layer raw material into the mold of the tablet machine, press and shape, and make A green tire...

specific Embodiment approach 1

[0036] First, the powdered catalyst is ground, or the powdered catalyst is ground and mixed with a binder to form a paste, or the powdered catalyst is ground and mixed with water to form a paste; in addition, the powdered carbon-containing precursor, or powder After the carbon-containing precursor is mixed with additives, one or more of crushing, grinding, and stirring are performed, and then mixed with water to form a paste. Among them, the raw material of the carbon film precursor layer is one or two of phenolic resin, petroleum coke, coal powder, carbon powder, graphite powder, and biomass powder, and the additives are carboxymethyl cellulose, sodium carboxymethyl cellulose, One or both of zinc chloride, sodium hydroxide, and hexamethylenetetramine; the raw material of the catalyst layer is one or more of nickel, platinum, silver, copper oxide, aluminum oxide, zinc oxide, or chromium oxide. The binder is one of epoxy resin, polyurethane, cellulose, acetal resin, melamine an...

specific Embodiment approach 2

[0037] First, the powdered catalyst is ground, or the powdered catalyst is ground and mixed with a binder to form a paste, or the powdered catalyst is ground and mixed with water to form a paste; in addition, the powdered carbon-containing precursor, or powder After the carbon-containing precursor is mixed with additives, one or more of crushing, grinding, and stirring are performed, and then mixed with water to form a paste. Among them, the raw material of the carbon film precursor layer is one or two of phenolic resin, petroleum coke, coal powder, carbon powder, graphite powder, and biomass powder, and the additives are carboxymethyl cellulose, sodium carboxymethyl cellulose, One or both of zinc chloride, sodium hydroxide, and hexamethylenetetramine; the raw material of the catalyst layer is one or more of nickel, platinum, silver, copper oxide, aluminum oxide, zinc oxide, or chromium oxide. The binder is one of epoxy resin, polyurethane, cellulose, acetal resin, melamine an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com