A carbon-based lightweight thermal protection material and its preparation method and application

A thermal protection material and lightweight technology, which is applied in the field of carbon-based lightweight thermal protection materials and their preparation, can solve the problems of inability to effectively suppress the temperature rise of aircraft, insufficient anti-airflow erosion performance, and low surface emissivity, and achieve Excellent air erosion resistance, good heat insulation effect, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

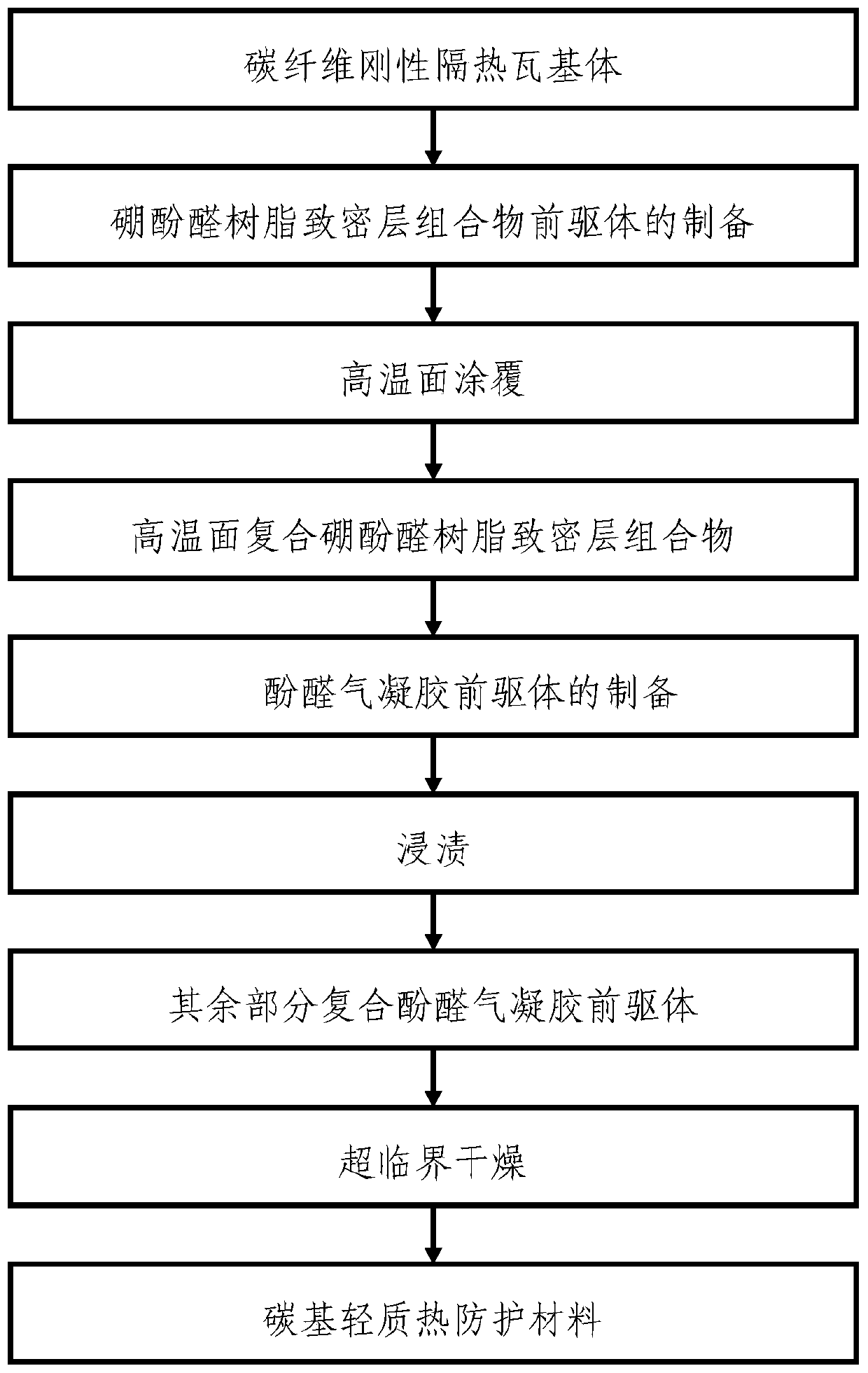

[0033] The process flow chart of the preparation method of the carbon-based lightweight thermal protection material provided by the present invention in the second aspect is as follows figure 1 Shown, specifically, described method comprises the following steps:

[0034] (1) Preparation of carbon fiber rigid insulation tile matrix:

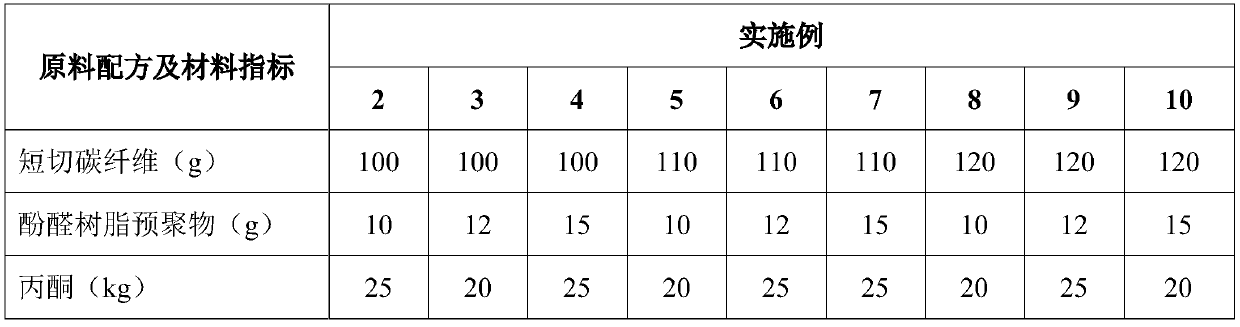

[0035] Mix chopped carbon fiber, phenolic resin prepolymer and acetone and stir evenly, filter, put the filter cake in a mold to form a green body, and the green body is sequentially subjected to gradient temperature rise, drying and curing, high temperature cracking and heat treatment to produce Obtain carbon fiber rigid insulation tile matrix. Specifically, chopped carbon fibers with a diameter of 14 to 16 microns (such as 14, 15 or 16 microns) and a length of 1 to 2 millimeters (such as 1, 1.5 or 2 millimeters), phenolic resin prepolymer and acetone according to (100 ~120): (10~15): (20000~25000) (for example, 100:10:20000, 100:10:22000, 100:...

Embodiment 1

[0042] First, add 100g of chopped carbon fiber with a diameter of 15 microns and a length of 1.5mm, 10g of phenolic resin prepolymer and 20kg of acetone into the mixing tank, stir for 1-2 hours to disperse evenly, filter, and place the filter cake in a mold for molding To obtain the green body, place the green body in a drying and curing machine, heat it at 120°C for 2 hours, at 140°C for 2 hours, at 160°C for 2 hours, and at 180°C for 2 hours to complete the gradient temperature rise drying and curing. Then heat up to 900°C in an argon-protected atmosphere furnace for cracking for 2 hours, heat up to 1800°C in an argon-protected atmosphere furnace and then heat-treat for 30 minutes to obtain a carbon fiber rigid heat-insulating tile. Then, get boron phenolic resin prepolymer 100g, borosilicate glass powder 5g, boron carbide 1g, silicon tetraboride 1g, molybdenum disilicide 2g and ethanol 200g mix uniformly, obtain boron phenolic resin compact layer composition precursor, boron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com