Oxygen-resistant molybdenum phosphide catalyst

A molybdenum phosphide catalyst, catalyst technology, applied in the direction of carbon compound catalyst, catalyst, physical/chemical process catalyst, etc., can solve the problem of difficult passivation layer thickness, and achieve the effect of excellent oxygen resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

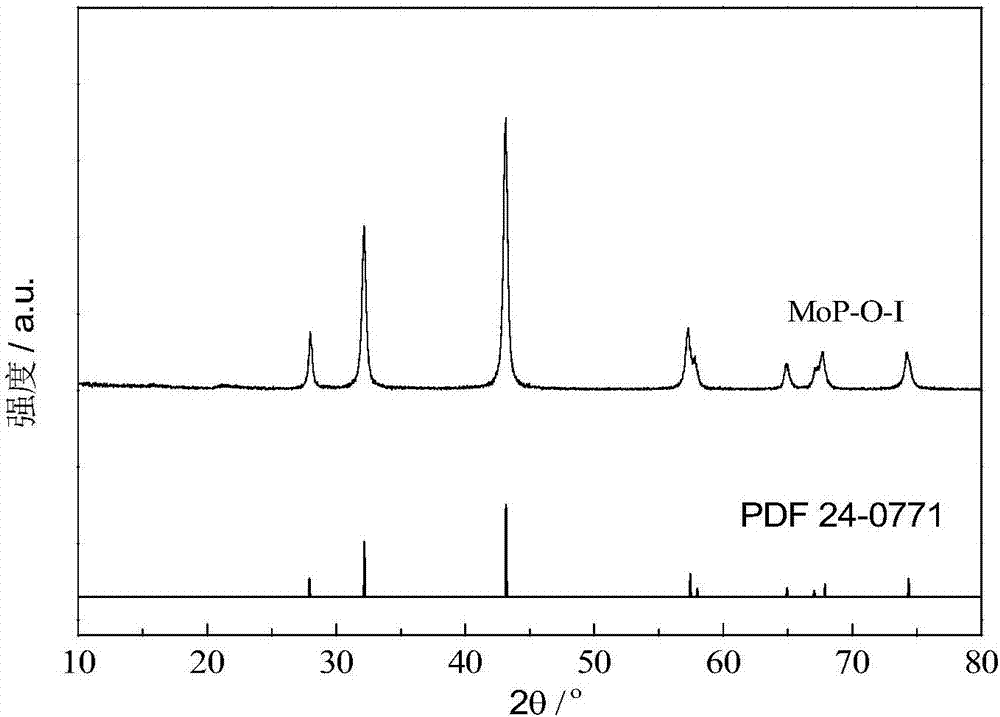

[0033] MoP was prepared by temperature-programmed reduction of phosphate precursors.

[0034] At room temperature, 2.57 grams of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 3.56 grams of diammonium phosphate ((NH 4 ) 2 HPO 4 ) was added to 20mL deionized aqueous solution, dissolved to obtain a clear and transparent solution, the solution was placed in an oven at 120°C for 12 hours to dry the moisture, and the obtained solid was roasted at 500°C for 6 hours to obtain the oxide precursor of MoP, wherein Mo The / P molar ratio was 1.

[0035] The phosphide catalyst was prepared by in-situ temperature-programmed reduction method. The temperature programming step mainly includes two steps: (1) in H 2 Under the atmosphere (flow rate 150mL / min), the temperature was raised from room temperature to 120°C at 5°C / min, and kept at 120°C for 1 hour to remove the water adsorbed by the catalyst; (2) from 120°C to 5°C / min. to 400°C, then the temperature was raised from 4...

Embodiment 2

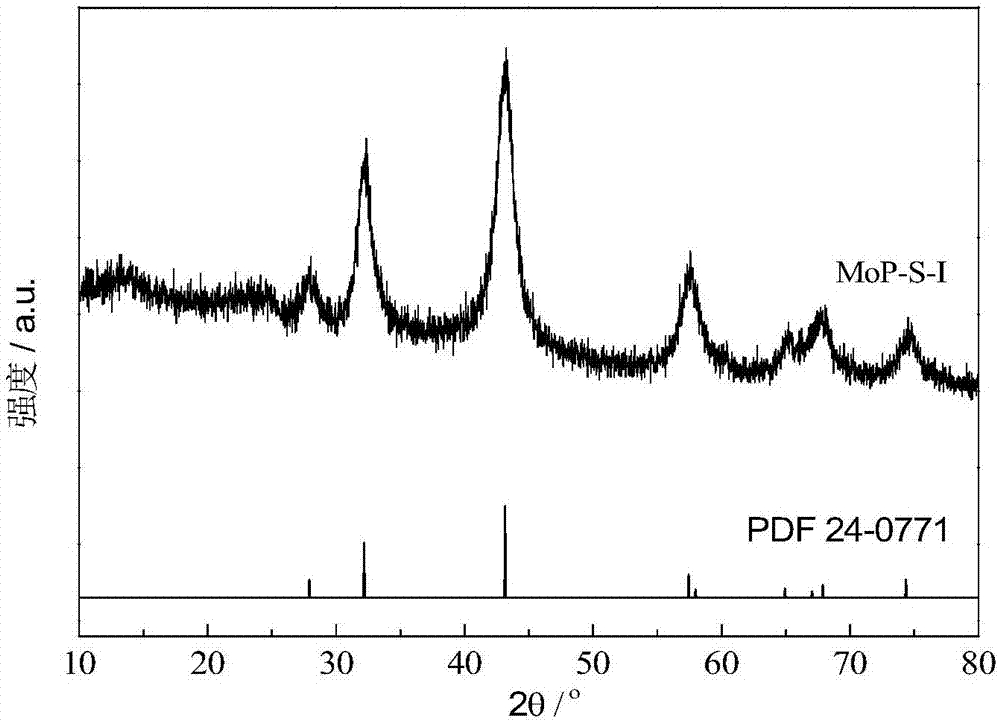

[0037] MoP prepared by temperature-programmed reduction of sulfur-containing precursors.

[0038] 3.8 grams of ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) be dissolved in 10ml ammonia water for subsequent use. 22 grams of ammonium sulfide ((NH 4 ) 2 S) Dissolve in 50mL of deionized water, then place in an ice bath, and slowly add 6.6mL of phosphorus trichloride (PCl 3 ) solution (95.5% in water). After the dropwise addition was completed, the ice bath was removed, and the ammonia solution of ammonium molybdate obtained before was slowly added dropwise to it. After reacting at room temperature for 1 hour, the three-necked flask was placed in the refrigerator until the crystals were completely formed. Suction filtration, the upper filter cake is washed with ethanol / water and then dried to obtain the catalyst precursor.

[0039] The phosphide catalyst was prepared by in-situ temperature-programmed reduction method. The temperature programming step mainly includ...

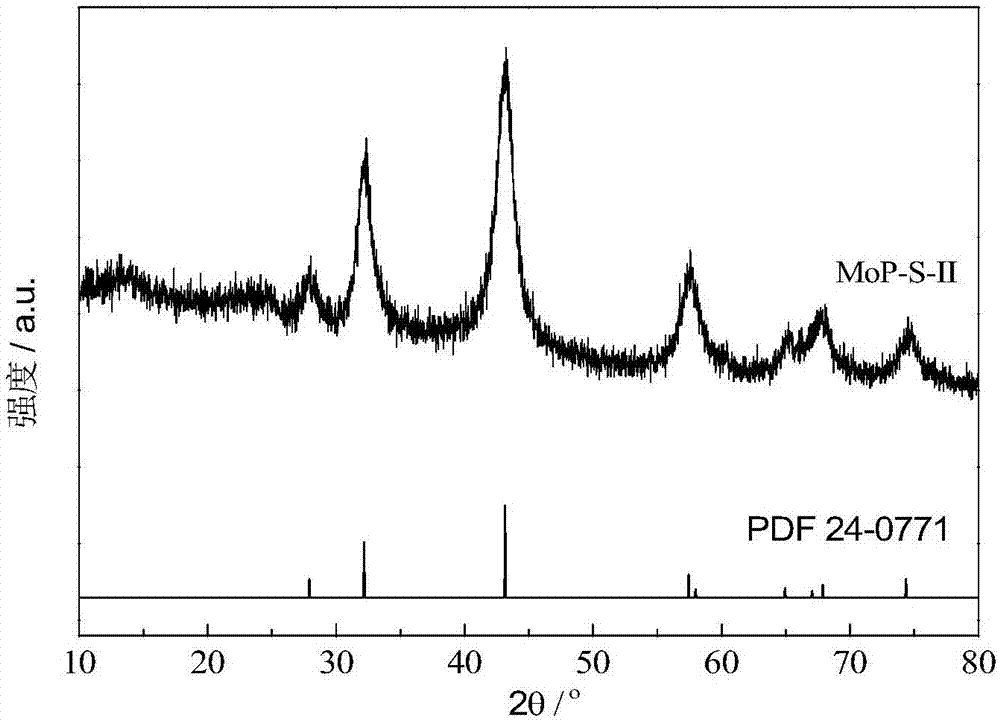

Embodiment 3

[0044] Ni 2 P 2 S 6 Reduction to prepare sulfur-containing Ni 2 P catalyst.

[0045] 75 grams of sodium sulfide (Na 2 S·9H 2 O) Dissolve in 100mL deionized water, then place in an ice bath, and slowly add 6.6mL of phosphorus trichloride (PCl 3 ) solution (95.5% in water). After the dropwise addition was completed, the ice bath was removed, and after reacting at room temperature for 1 hour, the three-neck flask was placed in the refrigerator until white crystals were completely formed. Then suction filtration, after the obtained white substance is recrystallized with ethanol / hot water solution, Na 4 P 2 S 6 The hydrate of Na can be obtained after drying 4 P 2 S 6 white solid. 1.8 g of Na 4 P 2 S 6 With 1.88 grams of nickel chloride (NiCl 2 ·6H 2 O) After fully grinding, put it into the quartz tube of the tube furnace, continuously feed high-purity nitrogen, treat it at 500 ° C for 10 hours, wash with ethanol / water solution and dry to obtain Ni 2 P 2 S 6 bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com