Fipronil production process

A production process, fipronil technology, applied in the field of fipronil production process, can solve problems such as low industrial production efficiency, hindering chloride metabolism, complex production process, etc., and achieve the goal of improving production efficiency, no risk, and reducing environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following specific embodiments describe the present invention in detail:

[0015] A fipronil production process, the steps are as follows:

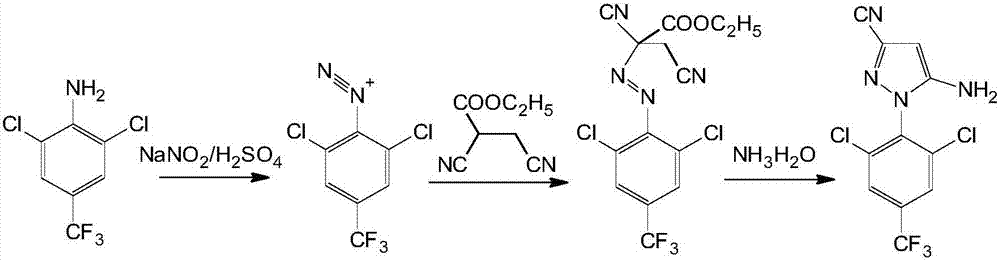

[0016] (1) Concentrated sulfuric acid and sodium nitrite are used as starting materials, react in glacial acetic acid solvent to generate nitrosyl sulfuric acid, and then carry out diazotization reaction with arylamine to generate arylamine diazonium salt, and then carry out condensation reaction with dicyanate , and finally rearrangement reaction with concentrated ammonia water in ammonia water medium to generate pyrazole.

[0017] The chemical reaction is:

[0018]

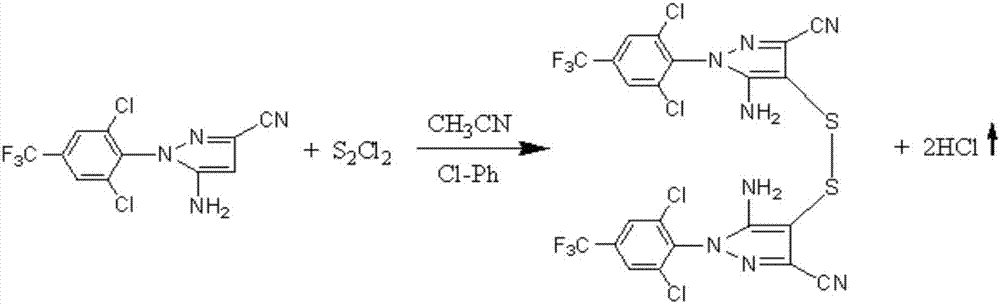

[0019] (2) Dissolve pyrazole in acetonitrile solvent, quickly add 13 sulfur at 20°C for reaction, continue stirring for 30 minutes after the temperature no longer rises, cool down, filter, and dry to obtain the sulfide product.

[0020] chemical reaction:

[0021]

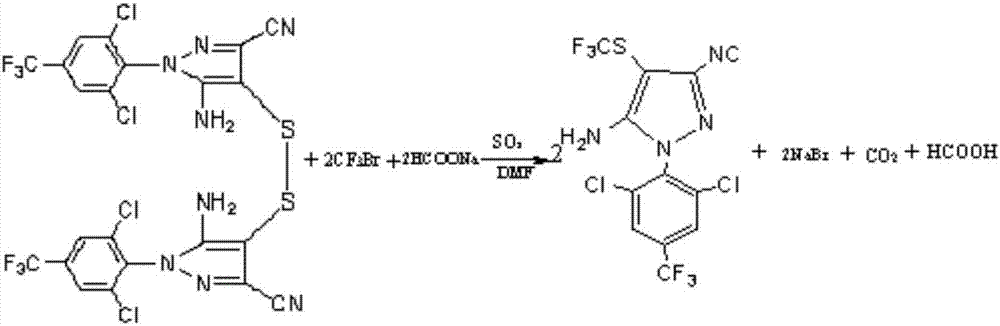

[0022] (3) Dissolve the sulfide in N,N-dimethylformamide, add sodium formate and fill wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com