Conductive ink, preparation method thereof, reel-to-reel conductive film and preparation method of reel-to-reel conductive film

A technology of conductive ink and conductive polymer, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of poor conductivity, low light transmittance, high haze, etc., and achieve high yield, high light transmittance, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] A preparation method of conductive ink, comprising:

[0066] Material preparation steps: prepare each raw material according to the formula ratio, and set aside;

[0067] Activation step: adding the silver nano wire dispersion liquid of the formulated amount into the second container, adding the wetting dispersant of the formulated amount, stirring and dispersing to activate the silver nano wires to obtain the first mixture, and set aside;

[0068] Hydrolysis step: add the formula amount of conductive polymer into the first container, then add the formula amount of organic solvent, water and stir, then add the formula amount of silane coupling agent under stirring state, so that the silane coupling agent is partially hydrolyzed, spare;

[0069] pH value adjustment step: after completing the hydrolysis step, under agitation, add a formulated amount of pH regulator to the first container to adjust the pH to 7-8, then add a formulated amount of polymer resin under agitati...

Embodiment 1

[0086] A conductive ink, comprising the following raw materials by mass percentage:

[0087] Nano silver wire dispersion liquid 50%, conductive polymer 0.1%, silane coupling agent 0.01%, viscosity regulator 0.1%, organic solvent 9.45%, deionized water 40%, polymer resin 0.1%, pH regulator 0.1% , Non-ionic surfactant 0.1%, wetting and dispersing agent 0.01%, leveling agent 0.01%, defoamer 0.01%, metal nanoparticles 0.01%.

[0088] A preparation method of conductive ink, comprising:

[0089] Material preparation steps: prepare each raw material according to the formula ratio, and set aside;

[0090] Activation step: adding the silver nano wire dispersion liquid of the formulated amount into the second container, adding the wetting dispersant of the formulated amount, stirring and dispersing to activate the silver nano wires to obtain the first mixture, and set aside;

[0091] Hydrolysis step: add the formula amount of conductive polymer into the first container, then add the f...

Embodiment 2

[0104] A conductive ink, comprising the following raw materials by mass percentage:

[0105] Nano silver wire dispersion liquid 50%, conductive polymer 0.1%, silane coupling agent 0.01%, viscosity regulator 0.1%, organic solvent 9.45%, deionized water 40%, polymer resin 0.1%, pH regulator 0.1% , Non-ionic surfactant 0.1%, wetting and dispersing agent 0.01%, leveling agent 0.01%, defoamer 0.01%, metal nanoparticles 0.01%.

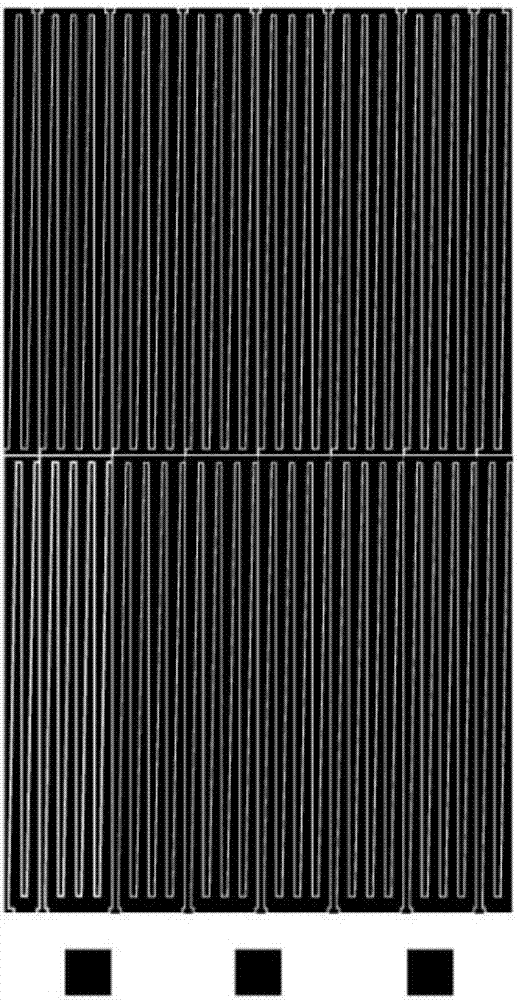

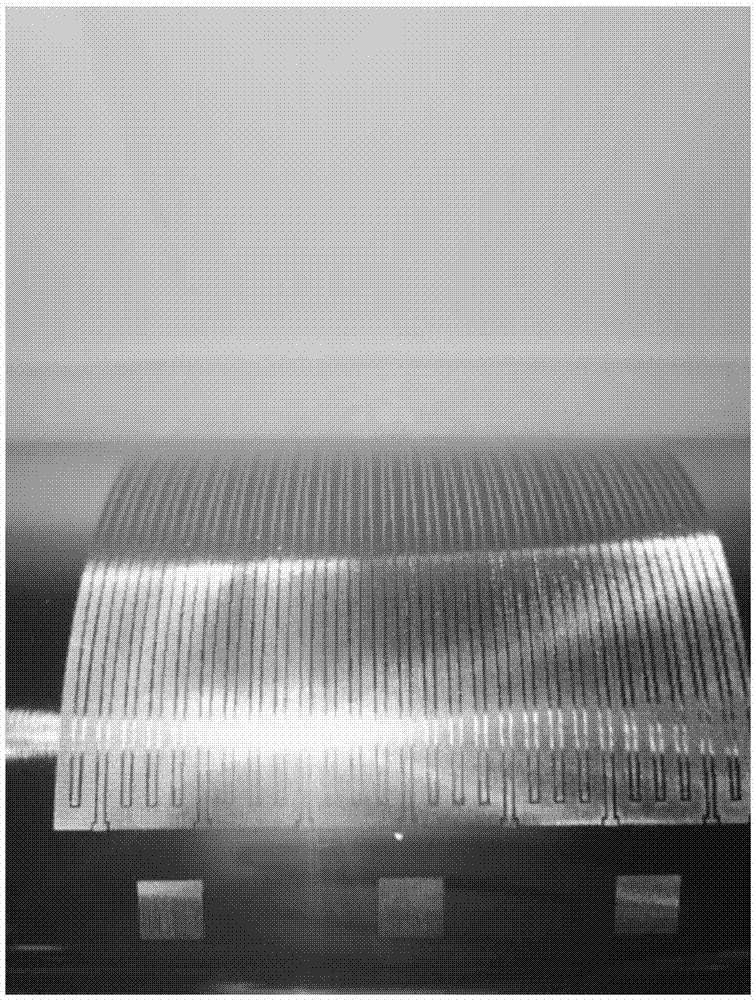

[0106] The difference in the preparation method of the roll-to-roll conductive film: Step 3: Plate roll production: The plate-making process of the roll-to-roll gravure plate roll usually engraves on the surface of the roll by electronic engraving. The inner layer of the drum is steel plate, the outer layer is copper-plated layer, the length is 550mm, and the circumference is 500mm. After the graphics are input into the computer, the computer transmits the signal to the electronic engraving machine, and engraves a 50um, 60 lines / cm solid-color rhombus patte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com