Perovskite solar cell with high-quality metal oxide electron transport layer and preparation method thereof

A technology of electron transport layer and solar cell, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problem of not being able to simultaneously and effectively reduce the density of defect states and the density of surface charge traps, so as to shorten the production cycle and avoid the cleaning process , The effect of surface flatness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

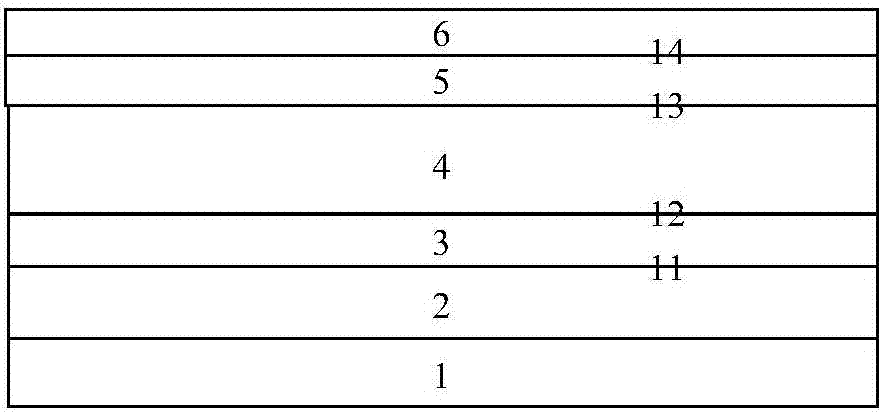

[0030] A method for preparing a perovskite solar cell with a high-quality metal oxide electron transport layer, comprising the following steps:

[0031] Step 1: Form a transparent conductive oxide electrode 2 on the glass substrate 1, and the transparent conductive oxide electrode 2 is formed by any one of the magnetron sputtering method, electron beam deposition method, spin coating method and non-vacuum chemical deposition method Prepared, the transparent conductive oxide electrode 2 is any material among fluorine-doped tin oxide FTO, indium tin oxide ITO, aluminum-doped zinc oxide AZO, and gallium-doped zinc oxide GZO;

[0032] Step 2: After preparing the transparent conductive oxide electrode 2, use the plasma-enhanced chemical vapor deposition method to bombard the plasma of fluorine-containing elements to generate fluorine radicals in the chemical vapor deposition system, and carry out the treatment on the surface and body of the transparent conductive oxide electrode 2. ...

Embodiment 1

[0038] A method for preparing a perovskite solar cell with a high-quality metal oxide electron transport layer, comprising the steps of:

[0039] 1) Preparation of transparent conductive oxide electrode 2: based on figure 1 The structure uses the magnetron sputtering method to prepare the transparent conductive oxide electrode 2 on the glass substrate 1. Taking the target material fluorine-doped tin oxide FTO as an example, the deposition gas atmosphere is argon, the ratio is 30 sccm, and the deposition temperature is 23 °C , the deposition power is 180W, the deposition pressure is 1Pa, and the deposition thickness is 100nm.

[0040] 2) Treating the transparent conductive oxide electrode 2 with fluorine-based plasma: After step 1), the transparent conductive oxide electrode 2 is doped with fluorine by plasma enhanced chemical vapor deposition, and the gas atmosphere is tetrafluoromethane, The flow rate is 200sccm, the working pressure is 80Pa, the working power is 60W, the wo...

Embodiment 2

[0047] A method for preparing a perovskite solar cell with a high-quality metal oxide electron transport layer, comprising the steps of:

[0048] 1) Preparation of transparent conductive oxide electrode 2: based on figure 1 Structure The transparent conductive oxide electrode 2 is prepared on the glass substrate 1 by non-vacuum chemical vapor deposition method. Taking aluminum-doped zinc oxide AZO as an example, the precursors are aluminum acetate and zinc acetate, and the solvents are water and methanol, respectively. 90 mL, stirred at room temperature for 3 hours, and then filtered through a 0.2 μm filter. The deposition conditions are as follows, the deposition gas is air, the deposition temperature is 350° C., and the deposition thickness is 100 nm.

[0049] 2) Treating the transparent conductive oxide electrode 2 with fluorine-based plasma: After step 1), the transparent conductive oxide electrode 2 is doped with fluorine by plasma enhanced chemical vapor deposition, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Short circuit current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com