A kind of thiourea copolymer heat stabilizer and preparation method thereof

A heat stabilizer and copolymer technology, applied in the field of thiourea copolymer heat stabilizers and their preparation, can solve the problems of poor thermal stability, affecting the thermal stability of heat stabilizers, affecting the thermal stability of heat stabilizers, etc. , to achieve the effects of improving thermal stability, inhibiting autocatalysis, and reducing the formation of conjugated systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

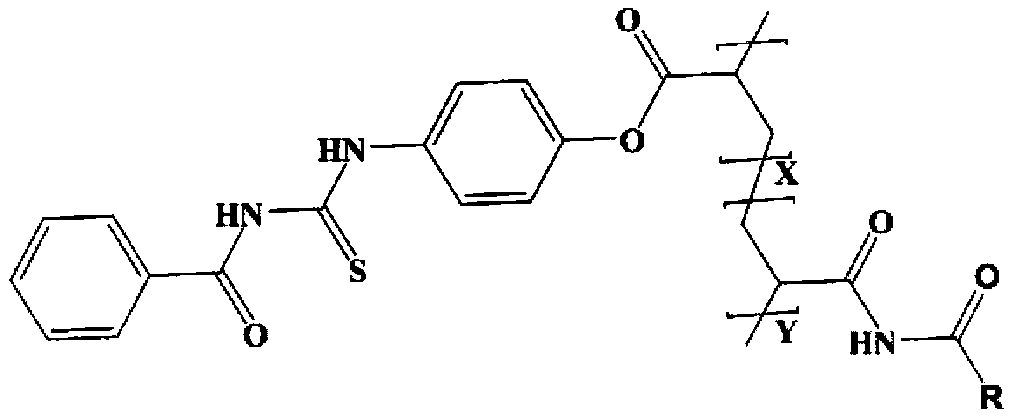

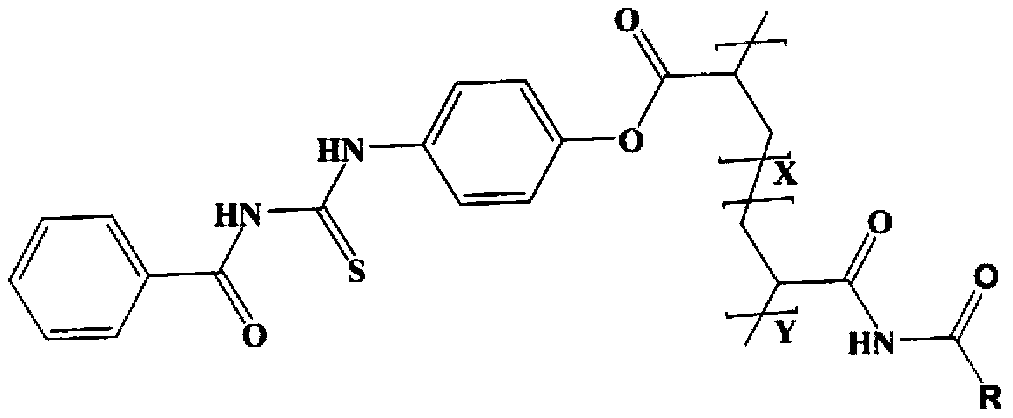

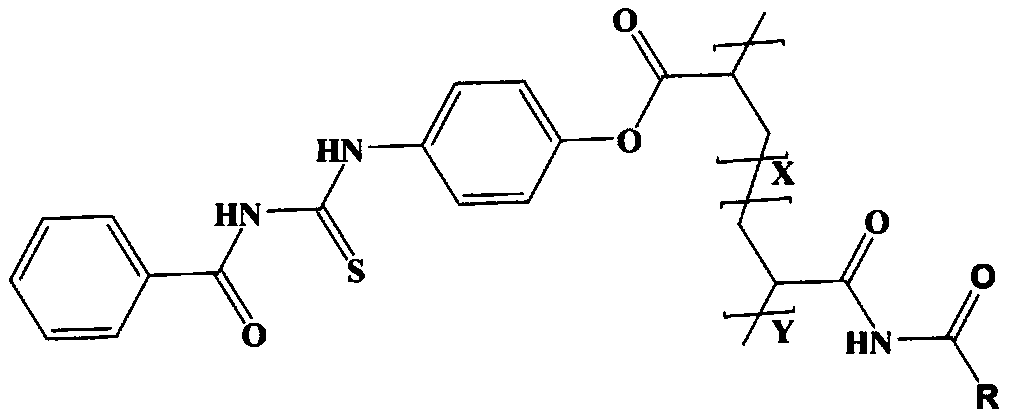

[0036] The preparation method of above-mentioned this thiourea copolymer thermal stabilizer is:

[0037]a. At room temperature, add the ammonium thiocyanate acetone solution with a concentration of 100~150g / L into the reaction kettle. Acyl chloride is added into the reaction kettle, after reaction at room temperature, centrifuged to obtain a mixture of benzoyl isothiocyanate and acetone. Add it to the above-mentioned benzoyl isothiocyanate-acetone mixture, heat up, and react. According to the mass ratio of acryloyl chloride to benzoyl chloride is 0.5:1-0.9:1, add acryloyl chloride to the above-mentioned reaction liquid, heat up, After the reaction, it was cooled to room temperature and centrifuged to obtain 4-(3-benzoylthioureido)phenylacrylate, washed with absolute ethanol 4 to 6 times the quality of benzoyl chloride, and dried in vacuo to obtain 4- (3-benzoylthioureido)phenyl acrylate monomer;

[0038] b. At room temperature, add acrylamide-acetone solution with a concentr...

Embodiment 1

[0042] a. At 25°C, add 1.2L of 100g / L ammonium thiocyanate in acetone solution into the reactor, add 120g of benzoyl chloride into the reactor within 0.5h, react at 25°C for 1h, and centrifuge to obtain benzoyl Acyl isothiocyanate acetone mixture, add 96g of p-aminophenol to the above benzoyl isothiocyanate acetone mixture, heat up to 40°C, react for 3h, then add 78g of acryloyl chloride to the above reaction solution, Raise the temperature to 70°C, react for 6 hours, cool down to room temperature, and centrifuge to obtain 4-(3-benzoylthioureido)phenylacrylate, wash 3 times with 400g of absolute ethanol, and dry in vacuum at 60°C for 10h to obtain 4-(3-benzoylthioureido)phenyl acrylate monomer;

[0043] b. At 25°C, add 1.2L of 150g / L acrylamide-acetone solution into the reaction kettle, add 330g of N-piperazinecarboxylic acid into the reaction kettle, raise the temperature to 60°C, react for 7 hours, cool down to room temperature, and centrifuge. To obtain N-acryloyl piperazi...

Embodiment 2

[0047] a. At 25°C, add 1.2L of 100g / L ammonium thiocyanate in acetone solution into the reactor, add 60g of benzoyl chloride into the reactor within 1 hour, react at 25°C for 2 hours, and centrifuge to obtain benzoyl Isothiocyanate-acetone mixed solution, add 51g of p-aminophenol to the above-mentioned benzoyl isothiocyanate-acetone mixed solution, raise the temperature to 60°C, react for 6h, add 45g of acryloyl chloride to the above-mentioned reaction solution, heat up After reacting for 8 hours at 85°C, cool down to room temperature, and centrifuge to obtain 4-(3-benzoylthioureido)phenylacrylate, wash with 200g of absolute ethanol three times, and dry in vacuum at 60°C for 10h to obtain 4 -(3-benzoylthioureido)phenyl acrylate monomer;

[0048] b. At 25°C, add 1.2L of 200g / L acrylamide-acetone solution into the reaction kettle, add 440g of N-piperazinecarboxylic acid into the reaction kettle, raise the temperature to 80°C, react for 9 hours, cool down to room temperature, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com