Unsaturated polyether, light-cured resin and preparation method of unsaturated polyether

A technology of unsaturated polyether, which is applied in the field of unsaturated polyether, photocurable resin and its preparation, can solve the problems of long curing time and achieve the effects of fast photocuring speed, high crosslinking density and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In this specific embodiment, a preparation method of unsaturated polyether is provided, comprising the following steps: adding a dihydric alcohol or a polyhydric alcohol as an initiator in a reaction vessel, adding an active metal cation catalyst, vacuum dehydration treatment, passing an inert gas, adding a chain extender to the reaction vessel, the chain extender is glycidyl ether containing unsaturated bonds, glycidyl ester containing unsaturated bonds, glycidyl ether with photoactivity or glycidyl ether with photoactivity Glycerides; control the temperature of the reaction system at 0-140°C, and carry out ring-opening polymerization for 0.5-3 hours at a stirring speed of 300-500 rpm to prepare unsaturated polyether.

[0024] Wherein, the initiator is dihydric alcohol or polyhydric alcohol.

[0025] The chain extender is one or a mixture of glycidyl methacrylate, glycidyl methacrylate, glycidyl acrylate, glycidyl acrylate, allyl glycidyl ether, and allyl glycidyl este...

Embodiment 1

[0042] Weigh 0.1 mol (7.609 g) of propylene glycol and 0.8529 g of potassium hydroxide (active cationic catalyst) and add them into the reaction vessel. Vacuum dehydration at 80°C for 30 min. Nitrogen gas was introduced to maintain a certain nitrogen flow rate. Slowly add 0.6 mol (85.29 g) of glycidyl acrylate dropwise into the reaction vessel, and the dropping time is controlled within 30-60 minutes. After the glycidyl acrylate was added dropwise, the reaction was continued for 1 h. Stop heating, and neutralize the system with 0.1mol / L phosphoric acid aqueous solution until the pH of the system is neutral. Add 20ml of deionized water, stir at room temperature for 30min, distill under reduced pressure to remove the water in the system, wash the system with petroleum ether, and distill under reduced pressure to remove the petroleum ether in the system to obtain a hydroxyl-terminated unsaturated polyether.

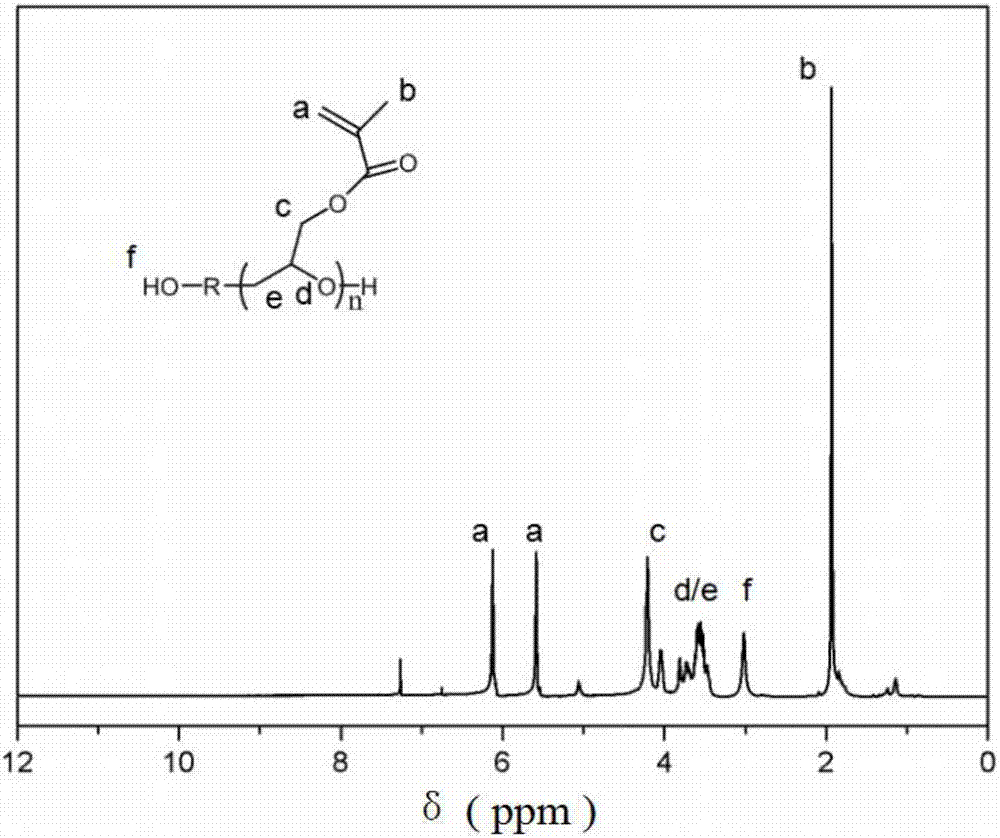

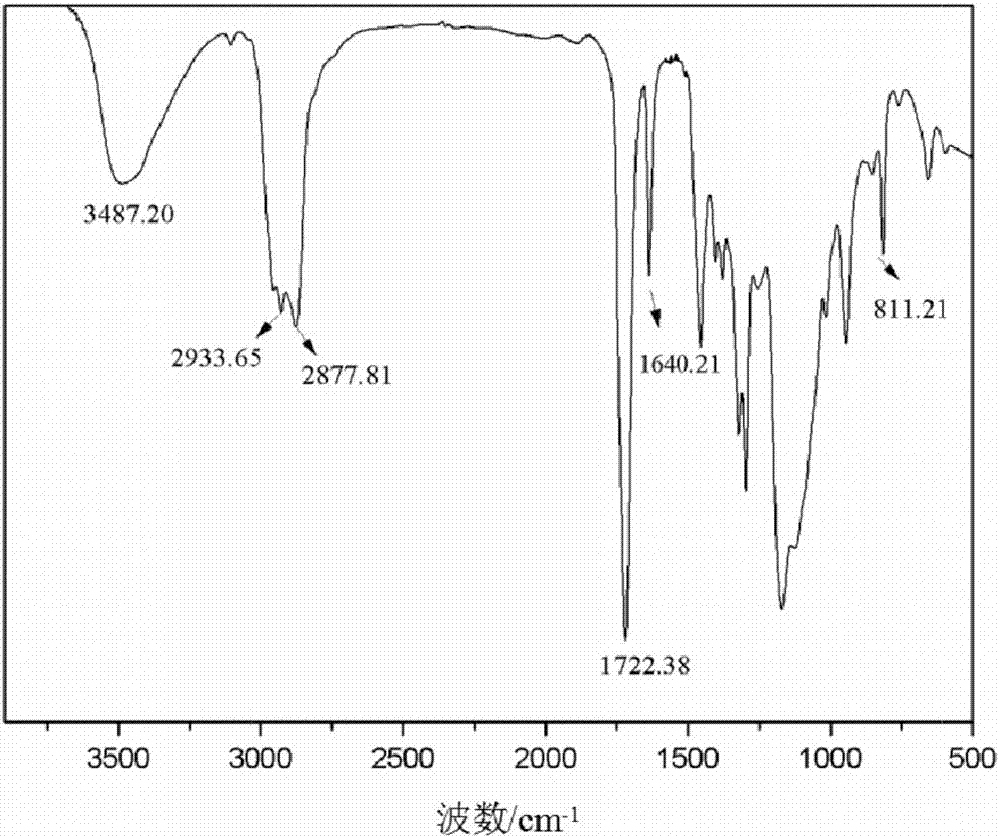

[0043] Such as figure 1 Shown is the NMR spectrum of the prepared h...

Embodiment 2

[0048] Weigh 0.17mol (12.94g) of propylene glycol into the reaction vessel, and vacuum dehydrate at 80°C for 30min. Nitrogen gas was introduced to maintain a certain nitrogen flow rate. Cool down to 65°C, add 1.135ml of cocatalyst trifluoroacetic acid into the reaction vessel, add 0.800ml of catalyst anhydrous tin tetrachloride into the reaction vessel, slowly add 1.02mol (145g) glycidyl acrylate dropwise into the reaction vessel For ester, the dropping time is controlled within 30-60min. After the glycidyl acrylate was added dropwise, the reaction was continued for 4h. Stop heating, add 150ml of dichloroethane, and let stand overnight (stand for about 24h). Filter to remove the lower layer liquid. Wash three times with methanol aqueous solution of disodium ethylenediamine tetraacetate, distill under reduced pressure, remove dichloroethane and water in the system, and obtain unsaturated polyether with terminal hydroxyl groups.

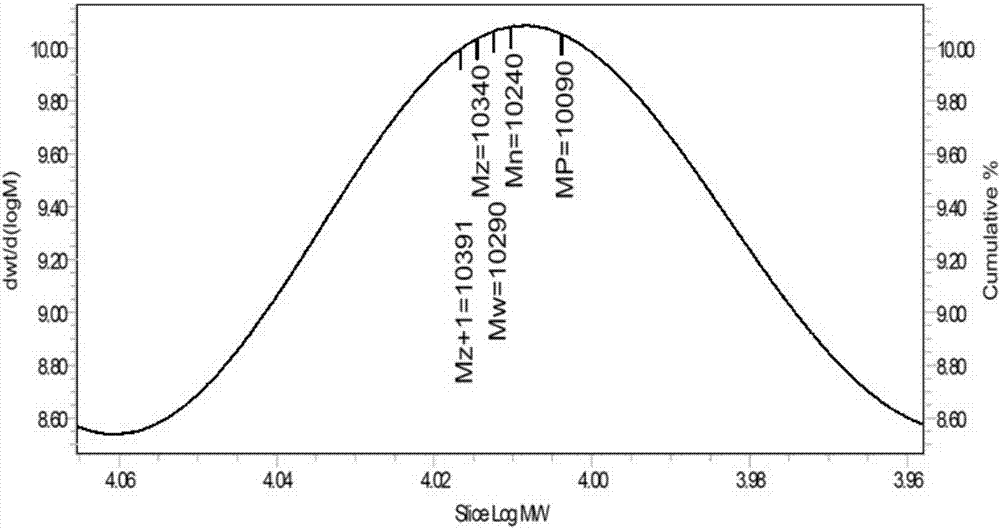

[0049] The hydroxyl-terminated unsaturated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com