Production process for tobacco bacterial wilt resistant compound microbial agent

A compound microbial inoculant, a technology for tobacco bacterial wilt, applied in the directions of microorganism-based methods, microorganisms, and chemicals for biological control, etc., can solve problems such as the inability to achieve long-term disease resistance, and enhance plant stress resistance. , Conducive to the effect of amplifying production and the production process is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

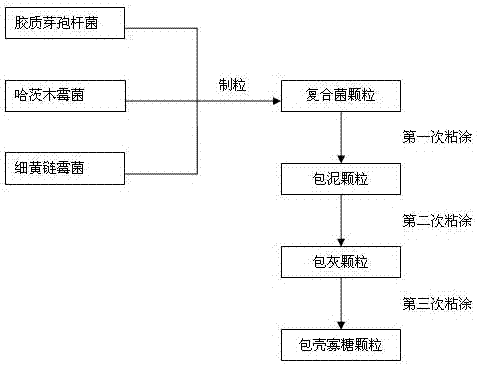

Method used

Image

Examples

Embodiment 1

[0023] a) Preparation of Bacillus colloidus cells: the strains were purchased from Beina Biology, strain number BNCC173119, 50 kg of culture medium was prepared, and the formula was 0.5 kg of peptone, 0.15 kg of beef extract, 0.25 kg of sodium chloride, pH 7.5, 121 Sterilize at ℃ for 30 minutes, insert the purchased strains, and culture on a shaking table at 150r / min for 24 hours to obtain the strains; prepare 1t of expansion medium, the formula is 40kg of beef extract, 9kg of yeast extract powder, 3kg of sodium chloride, pH7.5 , transferred to a fermenter for high-temperature sterilization, and after the sterilization, when the temperature dropped to 36°C, 50kg of the seed liquid was inserted, and the rotation speed was 120r / min for 26h, and the fermentation liquid was transferred to 4000r / min and centrifuged for 30min to obtain Bacillus colloidus Bacteria 128.7kg.

[0024] b) Preparation of Trichoderma harzianum thallus: purchased from Trichoderma Strain Collection Managemen...

experiment example 1

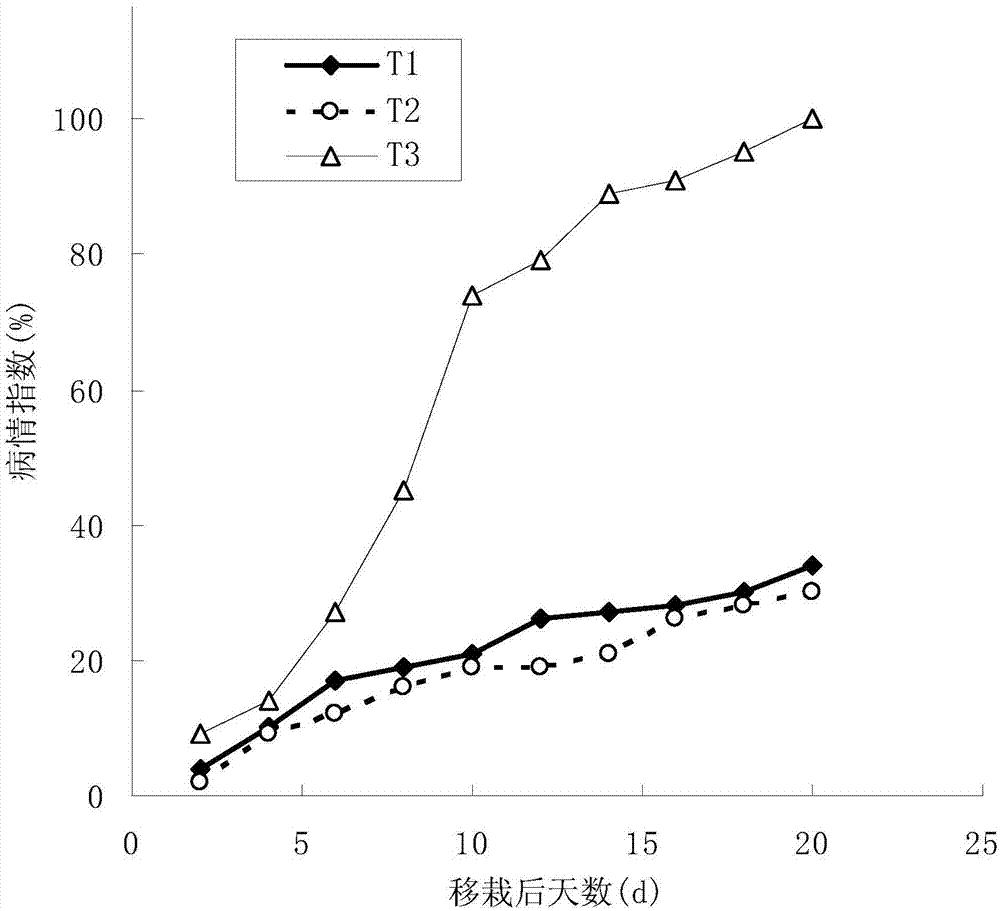

[0031] Experimental example 1: Tobacco bacterial wilt potted plant disease control test

[0032] Use the compound microbial inoculum produced by the method of embodiment 1 to carry out potted plant disease prevention test, test procedure is as follows:

[0033] The experimental tobacco variety was purchased locally as "China Tobacco 100". The bacterial wilt pathogen, R. solanacearum, was purchased from Beina Biological No. BNCC221120. The experimental soil was taken from the field of Youyi Village, Laishan Town, Yantai City, which is prone to tobacco bacterial wilt. Soil, texture sandy loam, pH=5.3, organic matter 7.3g / kg, total nitrogen (N) 0.762g / kg, total phosphorus (P 2 o 5 )0.577g / kg, total potassium (K 2 O) 15.3g / kg. Three treatments were set up in the test, which are: T1: root irrigation with Jinzhengda antimicrobial agent, the application rate is 3ml / m 2 ; T2: use the bacterial agent of the present invention to spread, and the application rate is 5g / m 2 ; T3: No b...

experiment example 2

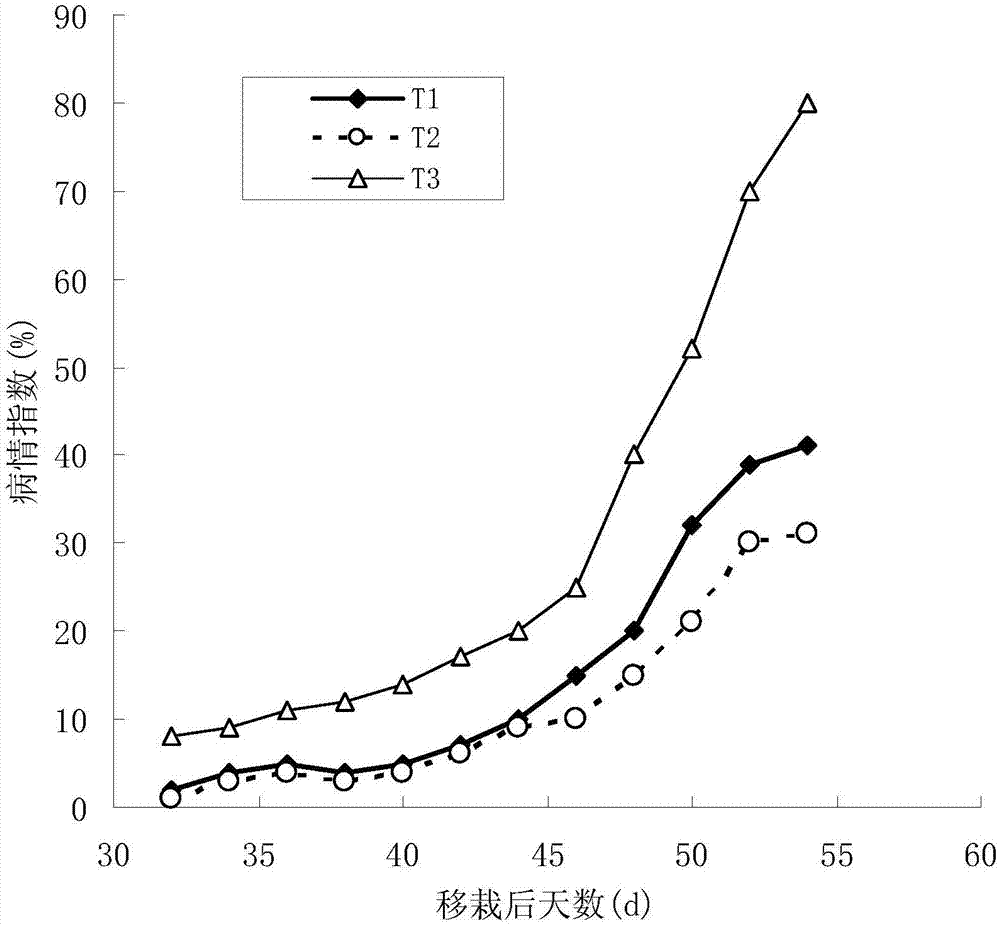

[0038] Experimental example 2: Field experiment on tobacco bacterial wilt control

[0039] Use the compound microbial bacterial agent produced by the method of embodiment 1 to carry out field test, from April 2016 to September 2016, carry out field test in Xiaohezi Village, Fushan District, Yantai City, and the experimental field for testing is the incidence rate of bacterial wilt disease in recent years. The more serious plots were spread with organic fertilizers, and the experimental tobacco variety was NC89. The test set 2 treatments, respectively: T1: use the bacterial agent of the present invention to spread, and the application rate is 5kg / 667m 2 ; T2: No bacterial agent was used as the control group. Each treatment was repeated 4 times, and the area of the plot was 100m 2 .

[0040] Observe the disease on 30d, 60d, 90d, and 120d after planting. Disease grade: 0 is asymptomatic on the leaves; 1 is wilting on the leaves below 1 / 4 of the plant; The surface of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com