A kind of zinc-rich yam chewable tablet and preparation method thereof

A technology of zinc-enriched yam and chewable tablets, which is applied to the functions of food ingredients, food ingredients containing natural extracts, food ingredients containing oligosaccharides, etc., can solve the problems of high starch content and low content of active ingredients in yam chewable tablets, etc. Achieve the effects of increasing intake, enhancing human immunity, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

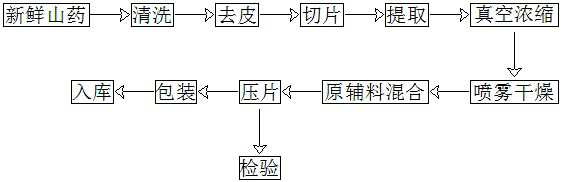

Method used

Image

Examples

Embodiment 1

[0035] 1) Cleaning, choose fresh and unscarred iron rod yam as raw material, use a special yam cleaning machine to clean the yam, and remove the sundries and soil attached to the yam;

[0036] 2) Slicing, peeling the cleaned yam, and then slicing with a multi-function slicer, the slice thickness is 2mm;

[0037] 3) Extraction, the cut yam slices are extracted at a ratio of 1:20 to obtain a mixture of material and liquid, the extraction temperature is 70°C, and the extraction time is 120 minutes;

[0038] 4), filtering, filtering the mixture of feed and liquid obtained in step 3), so as to realize the separation of the supernatant containing the extract from the yam tablets;

[0039] 5), concentrating, and vacuum concentrating the supernatant liquid obtained by filtering in step 4) to obtain a concentrated liquid, concentrating to a solid content of 20% (w / w);

[0040] 6) Drying: Use a spray dryer to dry the concentrated solution obtained in step 5) to prepare yam powder. The ...

Embodiment 2

[0045] 1) Cleaning, choose fresh and unscarred iron rod yam as raw material, use a special yam cleaning machine to clean the yam, and remove the sundries and soil attached to the yam;

[0046] 2) Slicing, peeling the cleaned yam, and then slicing with a multi-function slicer, the slice thickness is 3mm;

[0047] 3) Extraction, the cut yam slices are extracted at a ratio of 1:20 to obtain a mixture of material and liquid, the extraction temperature is 85°C, and the extraction time is 120 minutes;

[0048] 4), filtering, filtering the mixture of feed and liquid obtained in step 3), so as to realize the separation of the supernatant containing the extract from the yam tablets;

[0049] 5), concentrating, and vacuum concentrating the supernatant liquid obtained by filtering in step 4) to obtain a concentrated liquid, concentrating to a solid content of 25% (w / w);

[0050] 6) Drying: Use a spray dryer to dry the concentrated solution obtained in step 5) to prepare yam powder. The ...

Embodiment 3

[0055] 1) Cleaning, choose fresh and unscarred iron rod yam as raw material, use a special yam cleaning machine to clean the yam, and remove the sundries and soil attached to the yam;

[0056] 2) Slicing, peeling the cleaned yam, and then slicing with a multi-function slicer, the slice thickness is 3mm;

[0057] 3) Extraction, the cut yam slices are extracted at a ratio of 1:20 to obtain a mixture of material and liquid, the extraction temperature is 85°C, and the extraction time is 120 minutes;

[0058]4), filtering, filtering the mixture of feed and liquid obtained in step 3), so as to realize the separation of the supernatant containing the extract from the yam tablets;

[0059] 5), concentrating, and vacuum concentrating the supernatant liquid obtained by filtering in step 4) to obtain a concentrated liquid, which is concentrated to a solid content of 18% (w / w);

[0060] 6) Drying: Use a spray dryer to dry the concentrated solution obtained in step 5) to prepare yam powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com