Frictional water-based environment-friendly paint layer removing agent, and preparation method and application thereof

A cleaning agent and frictional technology, which is applied in the field of frictional water-based environmental protection paint layer cleaning agent and its preparation, can solve the problems of production cost pressure, strong volatility, environmental pollution, etc., and achieve low cost, low corrosion, and easy to use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

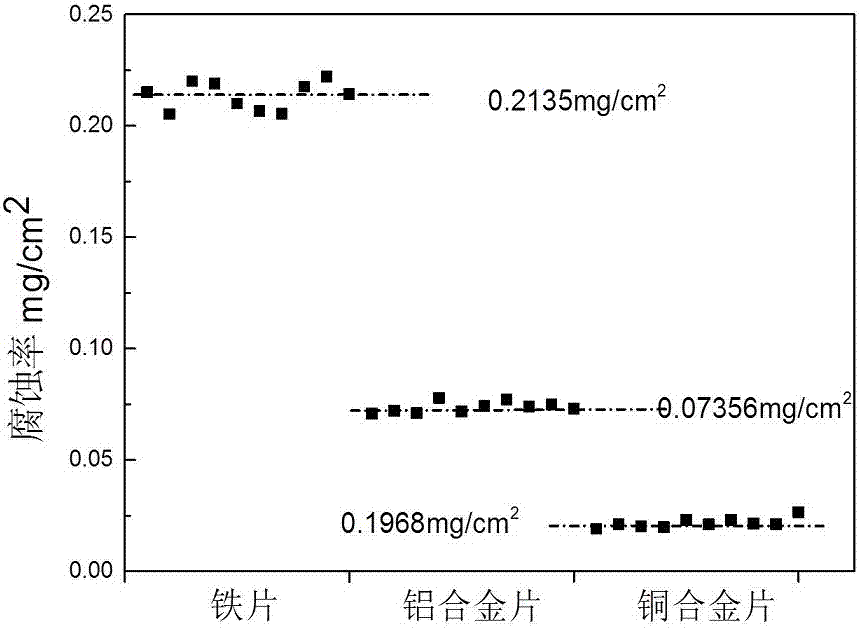

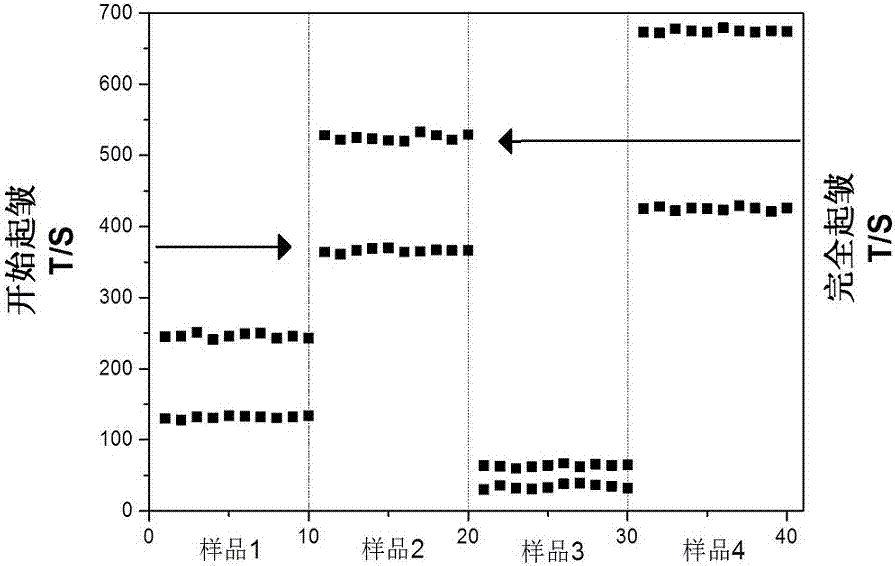

Embodiment 1

[0041] Composite main solvent: propylene glycol carbonate: ethylene glycol butyl ether = 2: (1~1.5), 25~40wt.%;

[0042] Co-solvent: γ-butyrolactone, 5~15wt.%;

[0043] Activator: acetic acid, 9~12wt.%;

[0044] Surfactant: cetyltrimethylammonium bromide: SPAN-80=1: (0.5~1), 2~3wt.%;;

[0045] Frictional particles: 0.05-1μm silicon oxide, 3~6wt.%;

[0046] Anti-aging agent: phenolic anti-aging agent, 2~3wt.%;

[0047] Penetrant: dioctyl sulfosuccinate sodium salt, 1~1.5wt.%;

[0048] Thickener: hydroxymethyl cellulose, 1.5~2wt.%;

[0049] Corrosion inhibitor: sulfonated lignin, 0.5~0.8wt.%;

[0050] Deionized water: ethanol volume ratio = 3:1, 10~25wt.%, marked as sample 1.

Embodiment 2

[0052] Main solvent: dimethyl succinate, 25~40wt.%;;

[0053]Co-solvent: γ-butyrolactone, 5~15wt.%;

[0054] Activator: Propionic acid, 9~12wt.%;

[0055] Surfactant: cetyltrimethylammonium bromide: SPAN-80=1: (0.5~1), 2~3wt.%;

[0056] Frictional particles: 0.05-1μm α-alumina particles, 3~6wt.%;

[0057] Anti-aging agent: phenolic anti-aging agent, 2~3wt.%;

[0058] Penetrant: dioctyl sulfosuccinate sodium salt, 1~1.5wt.%;

[0059] Thickener: methyl cellulose, 1.5~2wt.%;

[0060] Corrosion inhibitor: polyaspartic acid, 0.5~0.8wt.%;

[0061] Deionized water: ethanol volume ratio = 3:1, 10~25wt.%, marked as sample 2.

Embodiment 3

[0063] Main solvent: N-methylpyrrolidone, 25~40wt.%;

[0064] Co-solvent: n-propanol, 5~15wt.%;

[0065] Activator: lactic acid, 9~12wt.%;

[0066] Surfactant: betaine type surfactant, 2~3wt.%;

[0067] Frictional particles: 0.05-1μm silicon oxide, 3~6wt.%;

[0068] Anti-aging agent: phenolic anti-aging agent, 2~3wt.%;

[0069] Penetrant: dioctyl sulfosuccinate sodium salt, 1~1.5wt.%;

[0070] Viscous agent: hydrated lithium magnesium silicate, 1.5~2wt.%;

[0071] Corrosion inhibitor: sulfonated lignin, 0.5~0.8wt.%;

[0072] Deionized water: ethanol volume ratio = 3:1, 10~25wt.%, marked as sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com