Graphene/silicon dioxide-polypyrrole composite material as well as preparation method and application thereof

A technology of silica and composite materials, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of limited application and loss of specific surface area, and achieve low investment and increased The effect of low specific surface area and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Dissolve 0.6 g of graphite oxide solid in 500 mL of deionized water, add 5 g of cetyltrimethylammonium bromide and 0.4 g of sodium hydroxide, and sonicate for 3 h to obtain a modified graphene oxide suspension;

[0044] In this example, graphite oxide was prepared by the modified Hummers method. The specific steps are: take 120 mL of 98 wt% concentrated sulfuric acid in a beaker, and place it in an ice-water bath for electric stirring. When the temperature drops below 4 °C, add 5 g Graphite and 2.5 g of sodium nitrate, continue to stir for 1 h, then add 15 g of potassium permanganate, keep the temperature of the reaction system not exceeding 10 °C, continue to react for 2 h; transfer the beaker to a constant temperature water bath at 35 °C, and continue to stir for reaction 2 h; add 230 mL of deionized water to the beaker, and then control the temperature of the solution below 98 °C, continue the reaction for 30 min, then add 30 mL of 30 wt% hydrogen peroxide solutio...

Embodiment 2

[0057] (1) Dissolve 0.1 g of the graphene / silica composite material prepared in step (3) of Example 1 in 143 mL of deionized water. After ultrasonic treatment for 2.5 h, transfer to an ice-water bath at 0 °C, and add 0.4 g of pyrrole , after stirring for 2 h, add 25 mL, 0.2 g / mL ammonium persulfate solution dropwise, continue stirring for 11 h in ice bath at 0 °C, then add 10 mL of acetone to obtain a black precipitate;

[0058] (2) The black precipitate obtained in step (1) was filtered and washed with deionization and 500 mL of acetone respectively, then dried in an oven at 65 °C for 12 h, ground, and passed through a 60-mesh sieve to obtain graphene / dioxide Silicon-polypyrrole composite (GS-PPy).

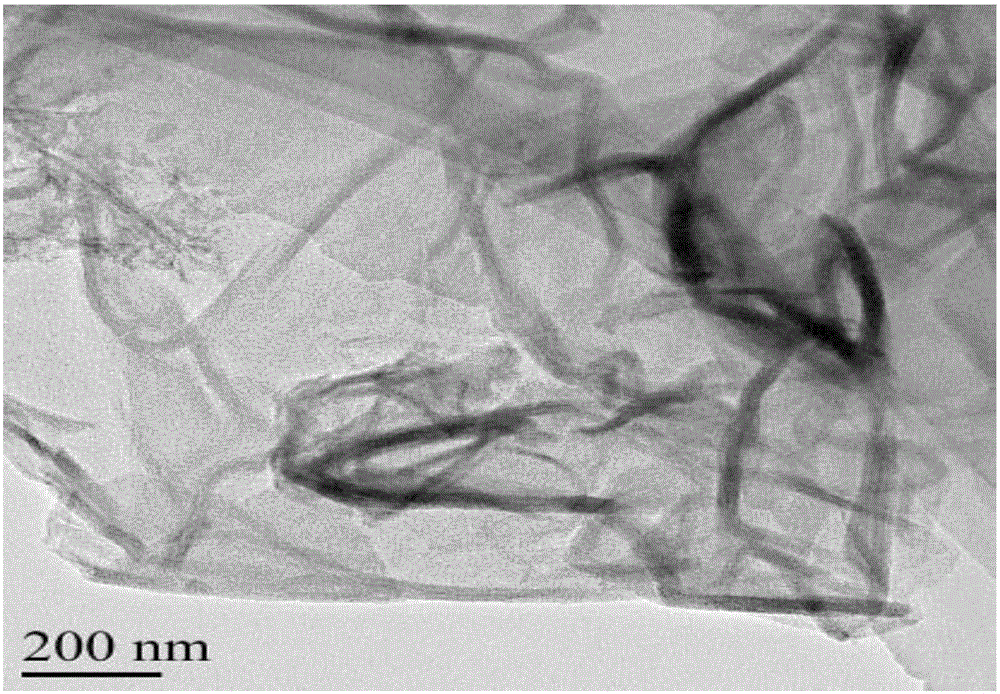

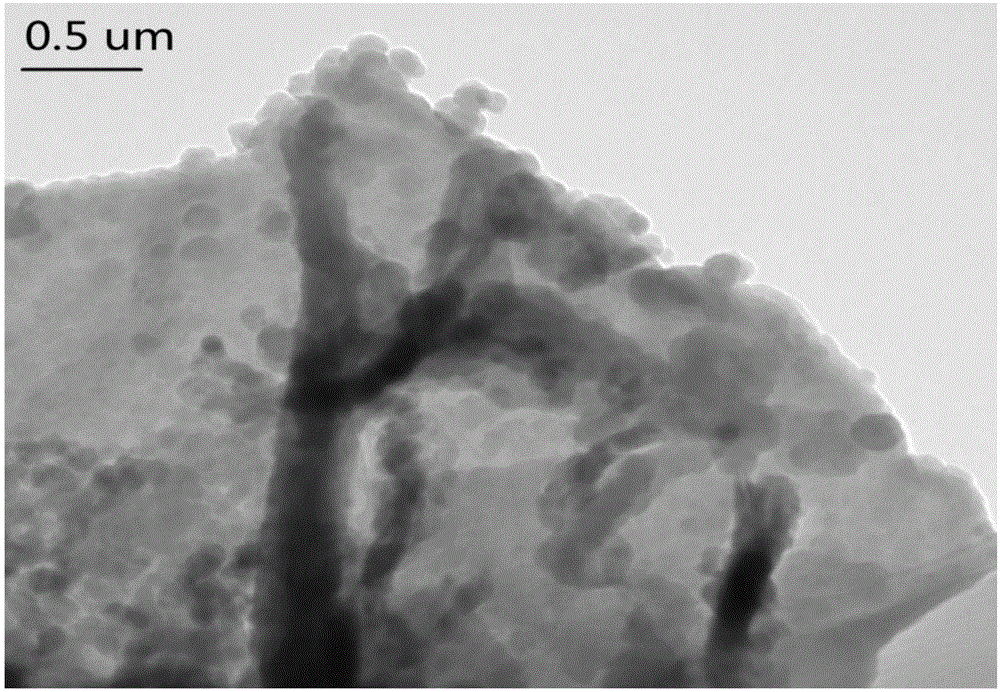

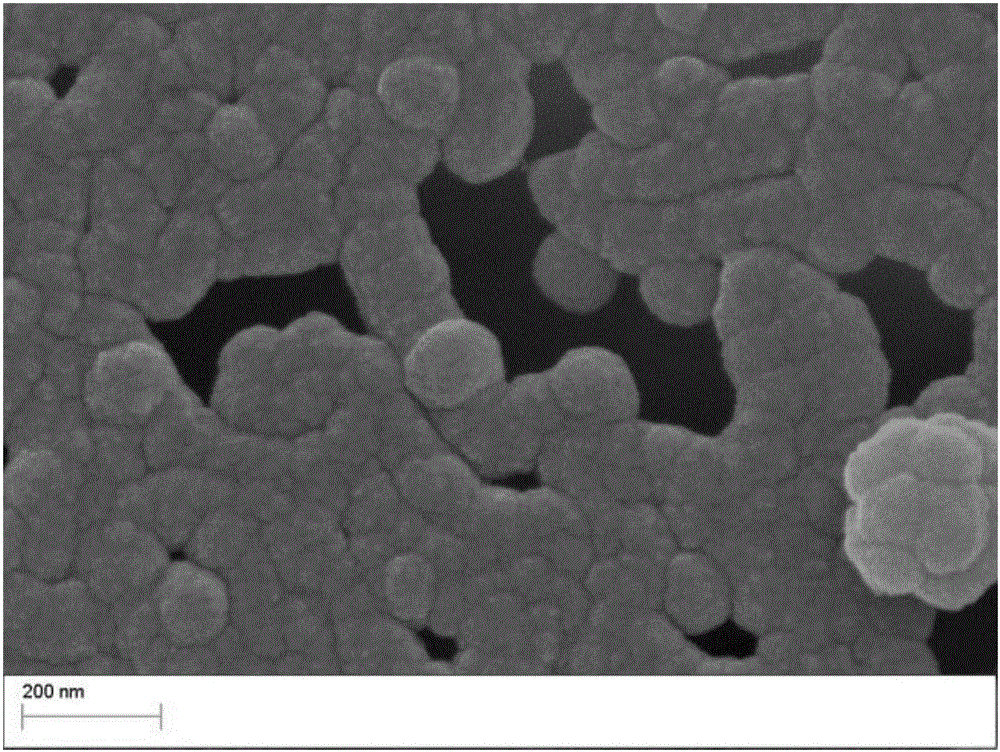

[0059] The microstructure, X-ray diffraction and X-ray photoelectron energy spectrum of graphene / silica-polypyrrole composite material in the present embodiment are similar to the graphene / silica-polypyrrole composite material of embodiment 1, illustrate this implementation In t...

Embodiment 3

[0066] (1) Dissolve 0.1 g of the graphene / silica composite material prepared in step (3) of Example 1 in 100 mL of deionized water, after ultrasonic treatment for 4 h, transfer to an ice-water bath at 0 °C, and add 0.7 g of pyrrole , after stirring for 3 h, add 35 mL, 0.3 g / mL ammonium persulfate solution dropwise, continue stirring for 14 h in ice bath at 0 °C, then add 10 mL of acetone to obtain a black precipitate;

[0067] (2) The black precipitate obtained in step (1) was filtered and washed with deionization and 500 mL of acetone respectively, then dried in an oven at 80 °C for 12 h, ground, and passed through a 60-mesh sieve to obtain graphene / dioxide Silicon-polypyrrole composite (GS-PPy).

[0068] The microstructure, X-ray diffraction and X-ray photoelectron energy spectrum of graphene / silica-polypyrrole composite material in the present embodiment are similar to the graphene / silica-polypyrrole composite material of embodiment 1, illustrate this implementation In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com