Spherical mesoporous calcium silicate/chitosan three-dimensional porous scaffold material, preparation method and application

A scaffold material, three-dimensional porous technology, applied in medical science, prosthesis, etc., can solve problems such as low bone fitness, insufficient bone fitness, irregular structure, etc., and achieve good biological functionality and good biocompatibility Sexuality, the effect of promoting bone regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

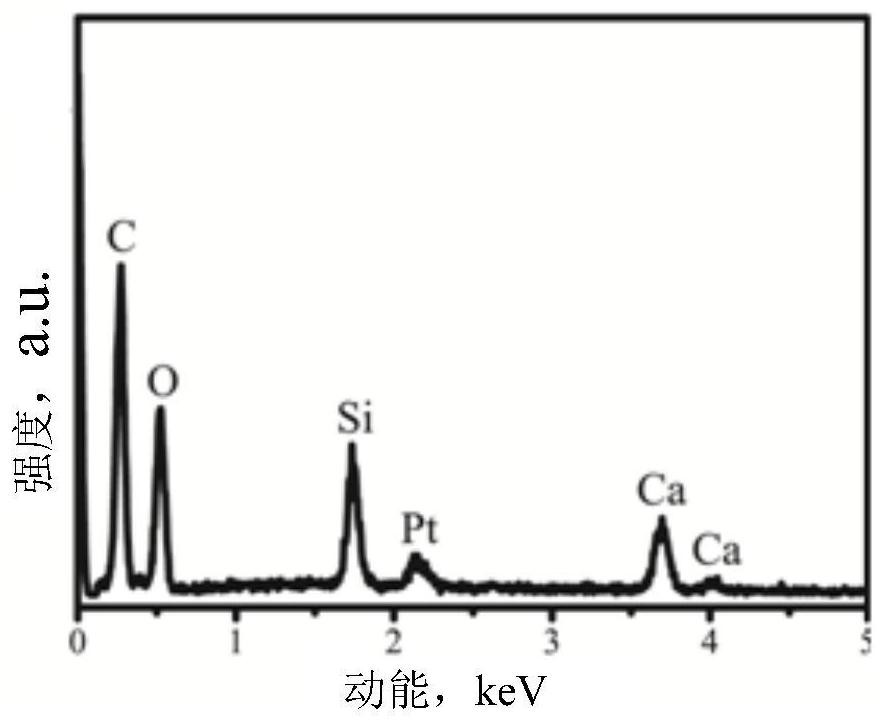

[0050] (1) Dissolve 1 g of cetyltrimethylammonium bromide (CTAB) in 350 mL of deionized water in a water bath at 25° C. to form a CTAB solution.

[0051] (2) Add 1.5mL of ammonia water with a concentration of 0.1mol / L to the CTAB solution, stir for 0.5h until the solution is completely dissolved, adjust the pH to about 10, then add 5mL tetraethyl orthosilicate (TEOS) and 5.2g nitric acid tetrahydrate in sequence Calcium, the molar weight of TEOS is about 22.47mmol, the molar weight of calcium nitrate tetrahydrate is about 22.03mmol, the molar ratio of silicon element and calcium element is about 1:1, the molar ratio of TEOS and CTAB is about 8:1, stir 2h, let stand for 12h, filter with suction, and wash 5 times with deionized water to obtain a white precipitate.

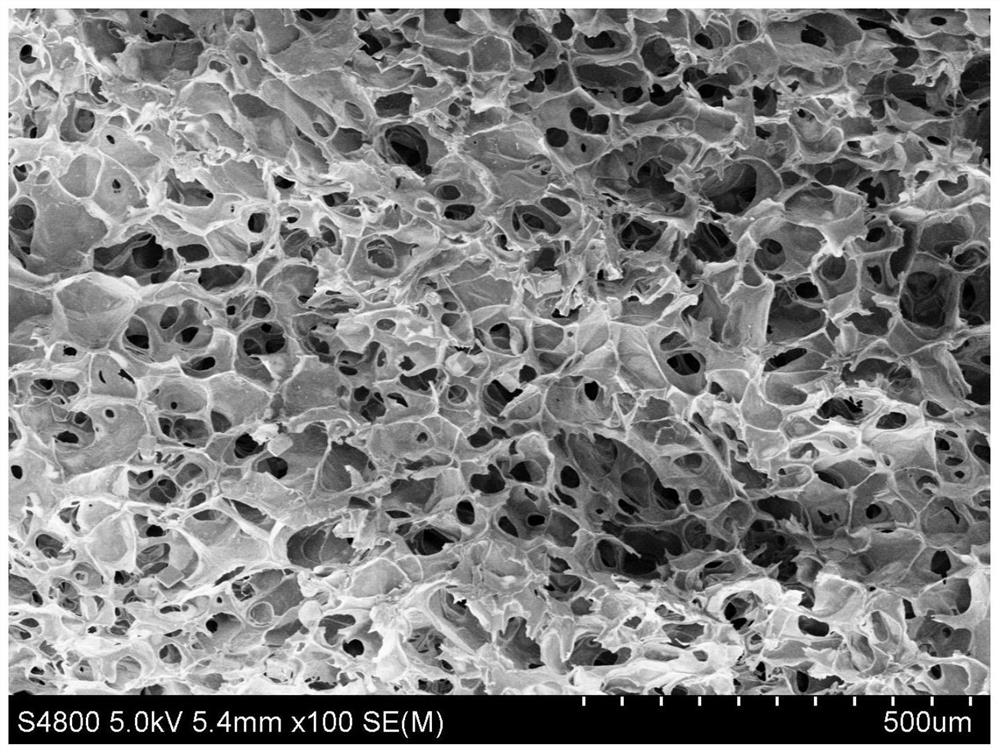

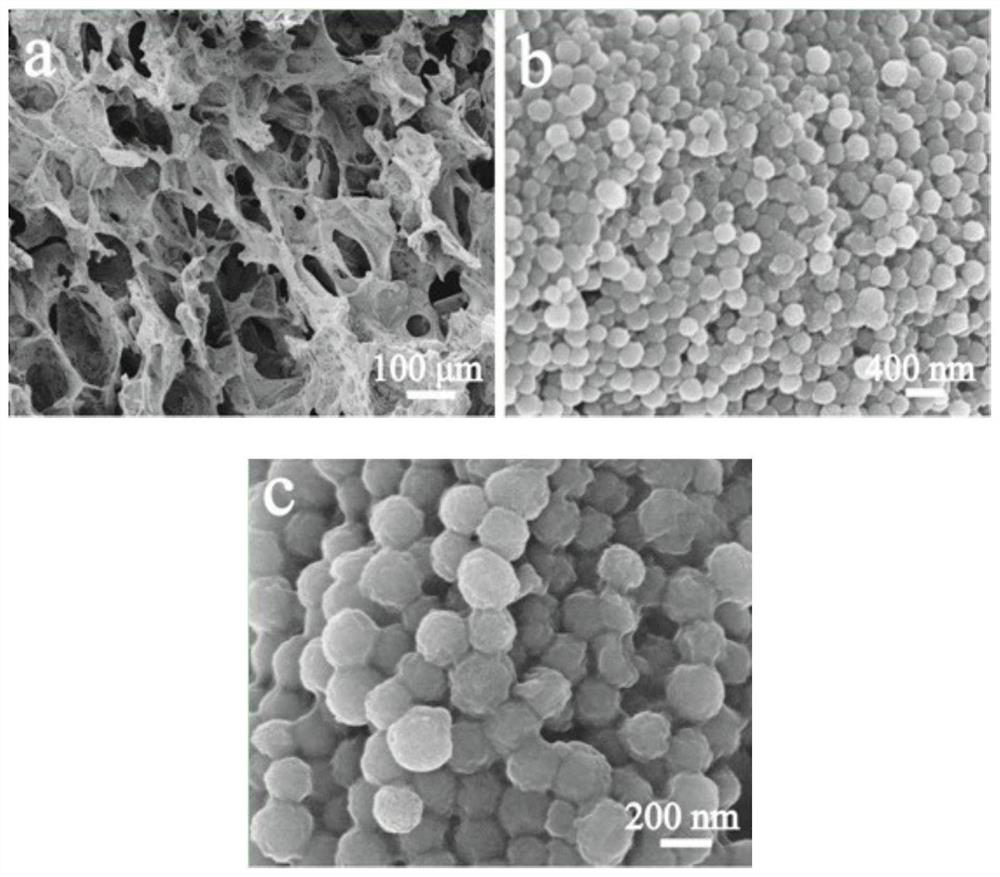

[0052] (3) The white precipitate obtained in step (2) was dried in an oven at 60°C, and then calcined at 500°C (2°C / min) in a muffle furnace for 4 hours to obtain spherical mesoporous calcium silicate. The average s...

Embodiment 2

[0060] (1) Dissolve 1 g of cetyltrimethylammonium bromide (CTAB) in 600 mL of deionized water in an oil bath at 80° C. to form a CTAB solution.

[0061] (2) Add 3 mL of ammonia water with a concentration of 12 mol / L to the CTAB solution, stir for 2 hours until it dissolves completely, adjust the pH to about 12, then add 8 mL of TEOS and 6.048 g of calcium hydrogen phosphate in sequence, the molar weight of TEOS is about 35.95 mmol, The molar weight of calcium nitrate tetrahydrate is about 35.16mmol, the molar ratio of silicon element and calcium element is about 1:1, and the molar ratio of TEOS and CTAB is about 13:1, stir for 5h, let stand for 48h, suction filter, use After washing with deionized water 5 times, a white precipitate was obtained.

[0062] (3) After the white precipitate obtained in step (2) was dried in an oven at 100°C, it was calcined at 700°C (2°C / min) in a muffle furnace for 8 hours to obtain spherical mesoporous calcium silicate. The average surface pore ...

Embodiment 3

[0070] (1) Dissolve 1 g of CTAB in 450 mL of deionized water in a 40°C water bath to form a CTAB solution.

[0071] (2) Add 2.4 mL of sodium hydroxide with a concentration of 6 mol / L to the CTAB solution, stir for 1 h until it is completely dissolved, adjust the pH to about 12.5, then add 7 mL of TEOS and 3.9 g of calcium chloride in sequence, the molar weight of TEOS is about 31.45mmol, the molar weight of calcium nitrate tetrahydrate is about 35.14mmol, the molar ratio of silicon and calcium is about 0.9:1, the molar ratio of TEOS and CTAB is about 11.4:1, stirring for 3h, standing for 24h, suction filtration , and washed 10 times with deionized water to obtain a white precipitate.

[0072] (3) After the white precipitate obtained in step (2) was dried in an oven at 80°C, it was calcined at 600°C (2°C / min) in a muffle furnace for 6 hours to obtain spherical mesoporous calcium silicate. The average surface pore diameter of spherical mesoporous calcium silicate is 30nm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com