Method for preparing micro-texture self-lubricating ceramic guide rail

A self-lubricating, micro-textured technology, applied in the field of machine tools, can solve the problems of matrix plastic aging, lower machine precision, poor thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Take raw materials according to the mass percentage of alumina 97%, diopside 3%; Mix the weighed raw materials, add 0.8% (mass percentage, the same below) PVA and 0.5% ammonium polyacrylate, and remove Ionized water was mixed with a mass ratio of 3:2, put into a ball mill barrel made of polyurethane, and then sprayed and granulated for 100 hours; The temperature is 95~110℃, the feeding speed is controlled at 10~14ml / min, and the diameter of the nozzle hole is 1mm; the mixed powder after granulation is vacuum grouted, and the vacuum grouted blank is molded at 20~30 Dry at room temperature at a temperature of ℃, and the dried blank is compacted by cold isostatic pressing under an oil pressure of 180 MPa, and the holding time is 10 minutes; the ceramic blank after cold isostatic pressing is placed in the The gas-fired energy-saving intermittent sintering furnace is buried in the air, the sintering temperature is 1500°C, the heating time is 70 hours, and the h...

Embodiment 2

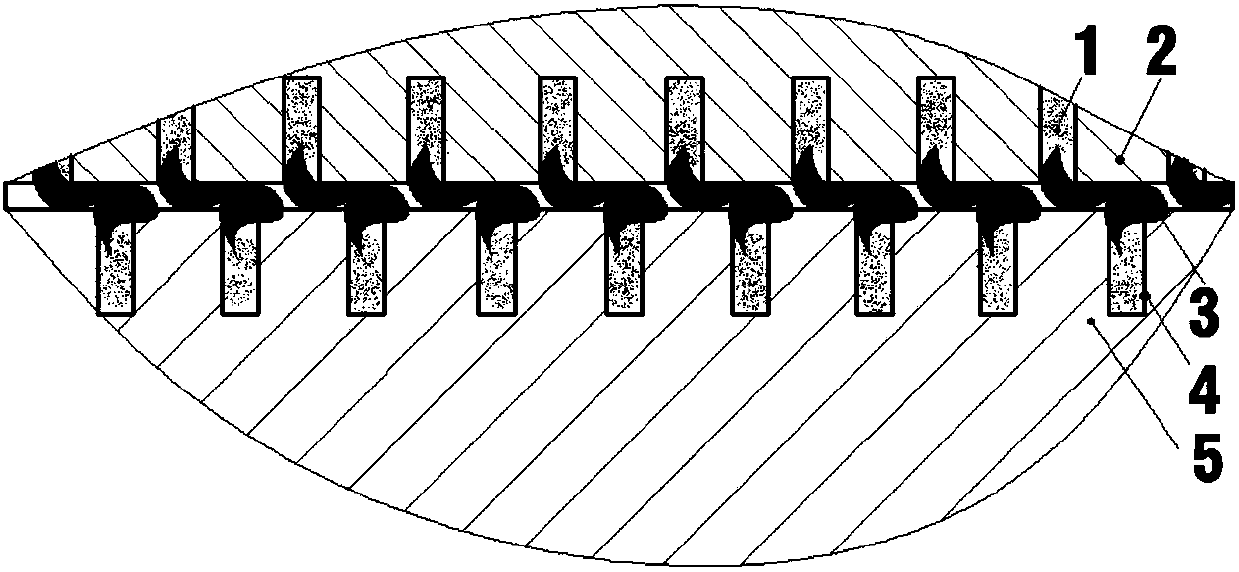

[0021] Embodiment two: other is the same as embodiment one, difference is to take raw material according to the mass percent of aluminum oxide 93%, diopside 4%, iron oxide 3%; During spray granulation, binding agent content is 1%, disperses The additive content is 0.8%; the cold isostatic oil pressure is 200MPa, and the sintering temperature is 1580°C. Microholes (4) are processed on the fixed guide rail (5) and the movable guide rail (2) by using femtosecond laser processing technology. Filled with MoS with a diameter of 1 μm 2 Grease. The bending strength of the ceramic guide rail is 321~349MPa, the Vickers hardness is 12~14GPa, the fracture toughness is 4.1~4.6, and the friction coefficient is 0.105 when the load is 200N and the speed is 300 mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com