A kind of preparation method and application of supported molybdenum oxide catalyst

A molybdenum oxide and catalyst technology, which is applied to the preparation of supported molybdenum oxide catalyst and its application field, can solve the problems such as difficulty in meeting the requirements of nano-size and specific surface area, and achieve the advantages of reactant diffusion and active site exposure and preparation. Simple method and the effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of molybdenum dichloride hydrate precursor: 2g molybdenum pentachloride MoCl 5 Mix with 6g powder at a mass ratio of 1:3, transfer to a tube furnace, roast at 650°C for 5h under a nitrogen atmosphere, then cool to room temperature, and then wash three times with 100ml of concentrated hydrochloric acid at 50°C with a concentration of 25wt%. , collect the washing solution, and put the washing solution in a low-temperature refrigerator to stand overnight to obtain yellow needle-like crystals, collect the crystals after filtration and dry to obtain the molybdenum dichloride hydrate precursor (H 3 O) 2 (Mo 6 Cl 8 )Cl 6 ·6H 2 O;

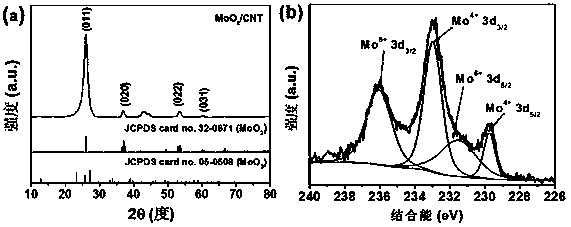

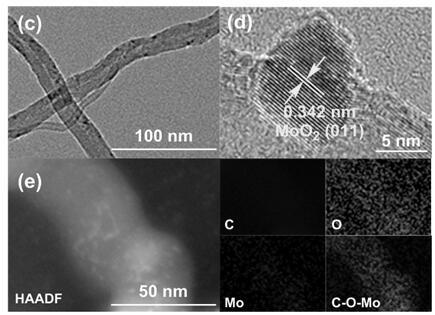

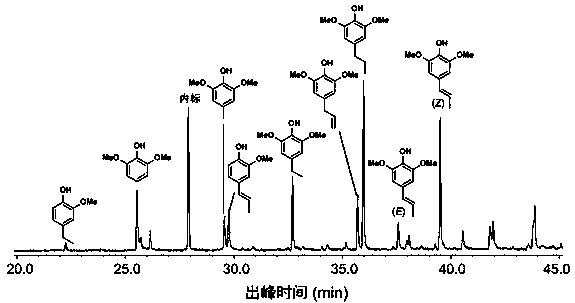

[0039] (2) Preparation of supported molybdenum oxide catalyst: The molybdenum dichloride hydrate precursor (H 3 O) 2 (Mo 6 Cl 8 )Cl 6 ·6H 2 O was dissolved in commercially available analytically pure methanol, and slowly added dropwise to multi-walled carbon nanotubes after it was completely dissolved. , after methanol wa...

Embodiment 2

[0043] (1) Preparation of molybdenum dichloride hydrate precursor: mix molybdenum pentachloride and molybdenum powder at a mass ratio of 1:2, transfer them into a tube furnace, and roast them at 600 °C for 5 h in an argon atmosphere, then Cool to room temperature, then wash three times with concentrated hydrochloric acid at 40°C with a concentration of 30wt%, collect the washing liquid, and put the washing liquid in a low-temperature refrigerator to stand overnight to obtain yellow needle-shaped crystals, collect the crystals after filtration and Dry to obtain molybdenum dichloride hydrate precursor (H 3 O) 2 (Mo 6 Cl 8 )Cl 6 ·6H 2 O;

[0044] (2) Preparation of supported molybdenum oxide catalyst: According to the mass ratio of molybdenum dichloride hydrate precursor to ethanol as 1:90, 500 mg of molybdenum dichloride hydrate precursor (H 3 O) 2 (Mo 6 Cl 8 )Cl 6 ·6H 2 O was dissolved in commercially available analytical pure ethanol to make solution A; 500 mg of zi...

Embodiment 3

[0050] (1) Preparation of molybdenum dichloride hydrate precursor: mix molybdenum pentachloride and molybdenum powder at a mass ratio of 1:5, transfer them to a tube furnace, and bake them at 700 °C for 5 h in a helium atmosphere, then Cool to room temperature, then wash three times with 60°C concentrated hydrochloric acid with a concentration of 20wt%, collect the washing liquid, and put the washing liquid in a low-temperature refrigerator to stand overnight to obtain yellow needle-shaped crystals, collect the crystals after filtration and Dry to obtain molybdenum dichloride hydrate precursor (H 3 O) 2 (Mo 6 Cl 8 )Cl 6 ·6H 2 O;

[0051] (2) Preparation of supported molybdenum oxide catalyst: The molybdenum dichloride hydrate precursor (H 3 O) 2 (Mo 6 Cl 8 )Cl 6 ·6H 2O was dissolved in commercially available analytically pure methanol, and slowly added dropwise to the mesoporous material SBA-15 after it was completely dissolved. The mass ratio of molybdenum dichlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com