Variable-scale CeO2 and CuO composite mesoporous spheres with high specific surface area and preparation method

A high specific surface area, cerium oxide technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Effective regulation, unfavorable large-scale production and application, and few reports on scale structure-activity relationship, etc., to achieve the effect of good monodispersity, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

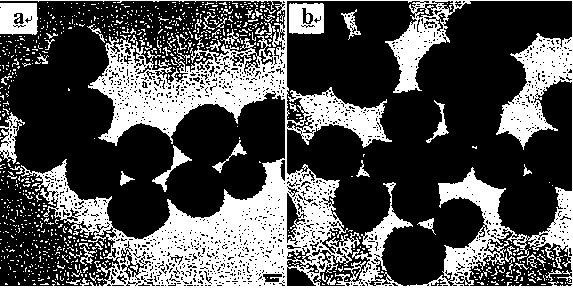

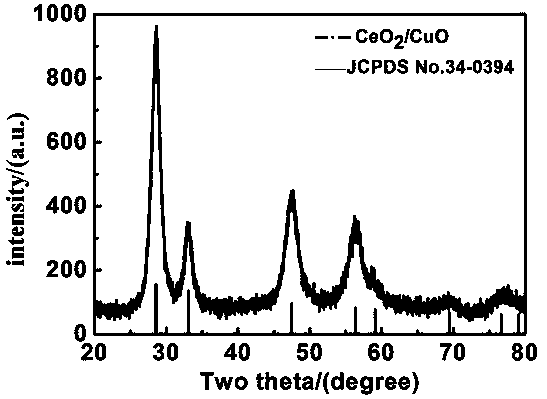

[0025] 30nm CeO 2 Preparation of / CuO composite mesoporous spheres

[0026]Under stirring conditions, add 1.4 milliliters of deionized water to 68.6 milliliters of ethylene glycol solution, stir evenly to obtain a water-containing ethylene glycol solution, then add 1.52 grams of cerium nitrate hexahydrate, stir for 30 minutes to completely dissolve the cerium nitrate, and place React in an oil bath at 180°C for 1 hour, cool naturally to room temperature, and calcine at 400°C for 4 hours after centrifugal drying to obtain cerium dioxide mesoporous spherical powder with a size of 30 nanometers, wherein the content of water in ethylene glycol is 2% , the concentration of cerium nitrate is 0.05 mol / liter; disperse 0.1 gram of the prepared cerium oxide mesoporous spherical powder into 10 milliliters of deionized water, and then, under stirring conditions, mix 7.5 milliliters of copper nitrate with a concentration of 0.01 mol / liter The solution is slowly added dropwise to the collo...

Embodiment 2

[0028] 60nm CeO 2 Preparation of / CuO composite mesoporous spheres

[0029] Under stirring conditions, add 2.45 milliliters of deionized water to 67.55 milliliters of ethylene glycol solution, stir evenly to obtain a water-containing ethylene glycol solution, then add 1.52 grams of cerium nitrate hexahydrate, stir for 30 minutes to completely dissolve the cerium nitrate, and place React in an oil bath at 180°C for 1 hour, cool naturally to room temperature, and calcine at 400°C for 4 hours after centrifugal drying to obtain a cerium oxide mesoporous spherical powder with a size of 60 nanometers, wherein the water content in ethylene glycol is 3.5% , the concentration of cerium nitrate is 0.05 mol / liter; disperse 0.1 gram of the prepared cerium oxide mesoporous spherical powder into 10 milliliters of deionized water, and then, under stirring conditions, mix 7.5 milliliters of copper nitrate with a concentration of 0.01 mol / liter The solution is slowly added dropwise to the col...

Embodiment 3

[0031] 110nm CeO 2 Preparation of / CuO composite mesoporous spheres

[0032] Under stirring conditions, add 3.5 milliliters of deionized water to 66.5 milliliters of ethylene glycol solution, stir evenly to obtain a water-containing ethylene glycol solution, then add 1.52 grams of cerium nitrate hexahydrate, stir for 30 minutes to completely dissolve the cerium nitrate, and place React in an oil bath at 180°C for 1 hour, cool naturally to room temperature, and calcine at 400°C for 4 hours after centrifugal drying to obtain a cerium oxide mesoporous spherical powder with a size of 110 nm, wherein the water content in ethylene glycol is 5% , the concentration of cerium nitrate is 0.05 mol / liter; disperse 0.2 g of the prepared cerium oxide mesoporous spherical powder into 20 milliliters of deionized water, and then, under stirring conditions, mix 15 milliliters of copper nitrate with a concentration of 0.01 mol / liter The solution is slowly added dropwise to the colloidal solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com