Multiple species inoculant and application thereof in fermenting organic waste to increase breeding of indigenous microbes to produce bio-organic fertilizer

A compound bacterial agent and fermentation tank technology, applied in the field of microorganisms and the environment, can solve the problems of high cost, single function, and inability to mix and ferment different organic wastes, and achieve the effect of saving resources and solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

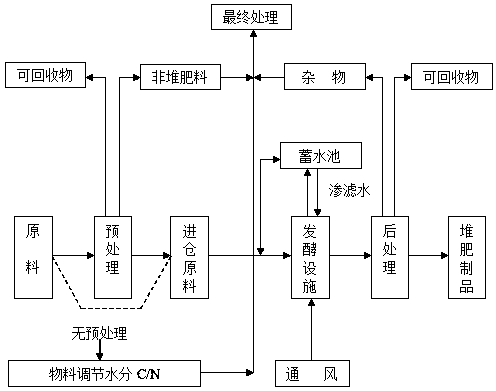

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1 adopts the following steps to prepare the composite bacterial agent of the present invention

[0085] 1. Preparation of pure dry powder of Bacillus carbonophilus:

[0086] (1) Activation culture of Bacillus carbonophilus: Inoculate the slant strain of Bacillus carbonophilus into the activation culture shake flask for activation culture. The activation medium formula is: beef extract 2.05g / L, peptone 0.45g / L, chloride Sodium 0.15g / L, yeast extract 1.40g / L, activated carbon powder 0.33g / L, pH 7.0; the activation culture conditions are: shake flask rotation speed 190rpm, culture at 29-30℃ for 22h to obtain liquid fermented seeds;

[0087] (2) Expansion culture and dehydration of Bacillus arborophilus: inoculate the obtained liquid fermented seeds into the expansion culture fermenter, the inoculation amount is 8.5%, the expansion medium formula is: maltose 30g / L, corn flour 16g / L, Yeast extract 4.8g / L, urea 3.0g / L, K 2 HPO 4 0.15g / L, MgSO 4 ·7H 2 O 0.015g...

Embodiment 2

[0113] Embodiment 2 adopts the pure thalline dry powder of 9 kinds of microbial bacteria that step 1-9 of embodiment 1 makes, according to the following ratio of the number of live bacteria in the pure thallus dry powder to the total number of live bacteria in the composite bacterial agent: Bacillus arborophilus 3 %, Bacillus amyloliquefaciens 5%, Geobacillus stearothermophilus 10%, Bacillus subtilis 30%, Streptomyces knowlesii 10%, actinomycetes fermentative 15%, Penicillium oxalicum 10%, Hansen 7% of Debaria yeast, 10% of Azotobacter rotundum, and the pure dry powder of 9 kinds of microbial bacteria are evenly mixed to prepare a composite bacterial agent.

Embodiment 3

[0114] Embodiment 3 adopts the pure thalline dry powder of 9 kinds of microbial bacteria that step 1-9 of embodiment 1 makes, according to the following ratio of the number of live bacteria in the pure thallus dry powder to the total number of live bacteria in the composite bacterial agent: Bacillus arborophilus 5 %, Bacillus amyloliquefaciens 9%, Geobacillus stearothermophilus 20%, Bacillus subtilis 15%, Streptomyces knowlesii 5%, actinomycetes fermentative 12%, Penicillium oxalicum 8%, Hansen 11% of Debaria yeast, 15% of Azotobacter rotundum, and the pure dry powder of 9 kinds of microorganisms are evenly mixed to prepare a composite bacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com