Vulcanized ionic liquid complex palladium catalyst, and preparation method and applications thereof

A technology of ionic liquid and palladium catalyst, which is applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, catalytic reaction, etc., can solve the problem that is not suitable for improving the deactivation and large-scale The limitations of the industrial application of production equipment, and the problems that have not been fundamentally resolved, have achieved good economics, industrial application value, high stability, and low load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

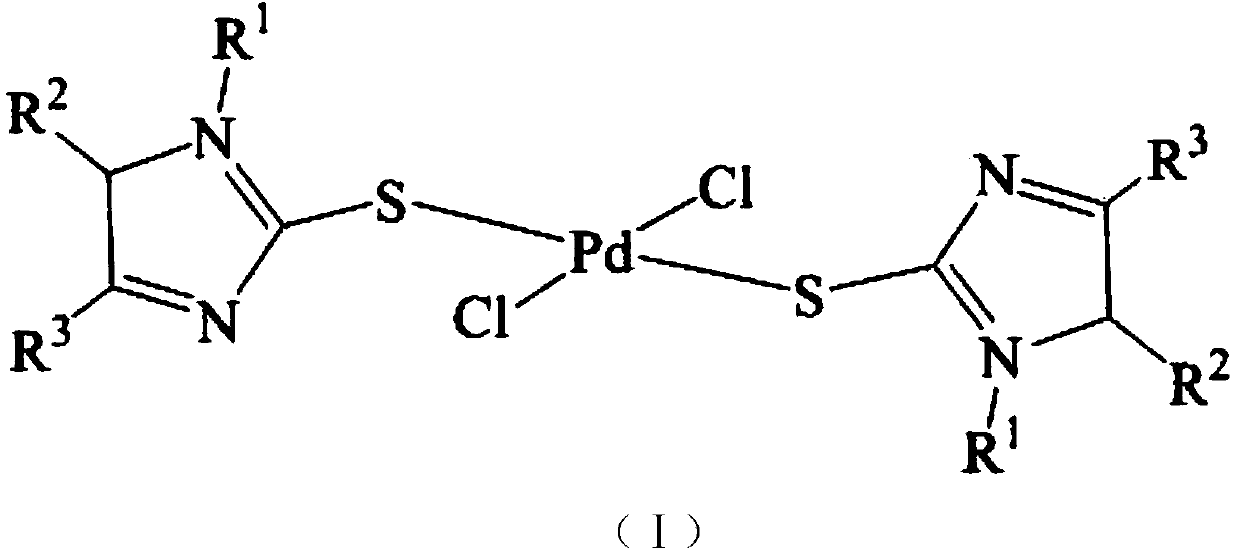

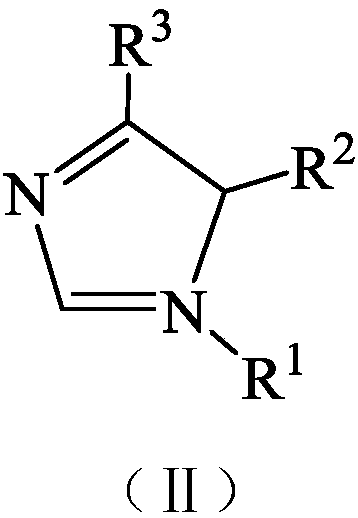

Method used

Image

Examples

Embodiment 1

[0066] Select columnar activated carbon as the carrier, its particle size is 40 mesh, the ash content is 3.0wt%, and the specific surface area is 950m 2 / g, the pore volume is 0.45mL / g, and treated with 300ml of 10wt% hydrochloric acid at 25°C for 3h. The treated carrier was washed with deionized water until neutral, dried at 110° C. for 12 hours, and then ready for use.

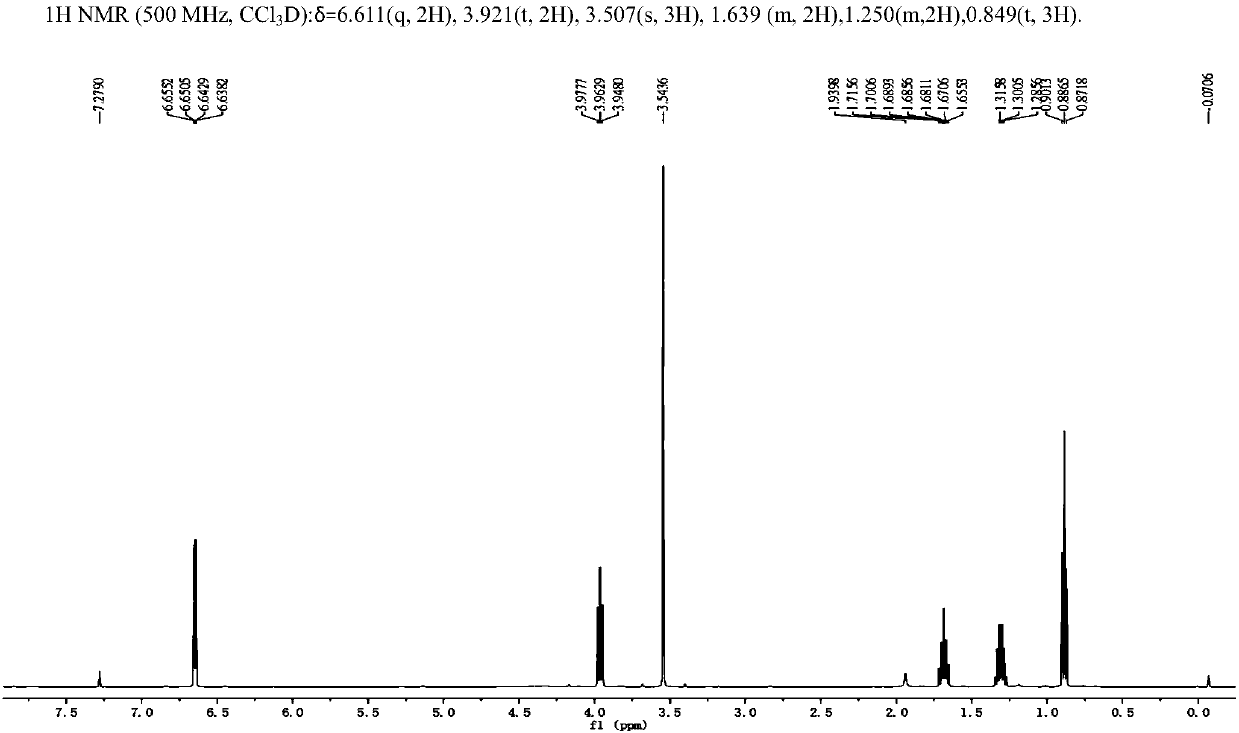

[0067] Synthesis of sulfide ionic liquid A:

[0068] Mix the ionic liquid 1-butyl-3-methylimidazolium chloride and sulfur powder at a mass ratio of 1:0.5, stir in a water bath at 40°C for 10 minutes, then add acetonitrile solution, dissolve, and stir at 40°C for 12 hours, Stir the above mixture evenly, then filter to remove unreacted sulfur powder, dry the obtained filtrate at 110°C, then dissolve the sample obtained after drying in dichloromethane, add an appropriate amount of Ionized water and sodium bicarbonate solution were used to further remove impurities in the solution. Finally, the above mixed sol...

Embodiment 2

[0072] The main difference between this example and Example 1 is that the types of ionic liquids are different, and its influence on the catalytic performance of the catalyst is studied.

[0073] Synthesis of sulfide ionic liquid B:

[0074] Mix ionic liquid 1-propyl-3-methylimidazolium tetrafluoroborate and sulfur powder according to the mass ratio of 1:0.5, stir in a water bath at 40°C for 10 minutes, then add acetonitrile solution, dissolve, and stir at 40°C After 12 hours, stir the above mixture evenly, then filter to remove unreacted sulfur powder, and dry the obtained filtrate at 110°C, then dissolve the sample obtained after drying into dichloromethane, add Appropriate amount of deionized water and sodium bicarbonate solution to further remove impurities in the solution, and finally, dry the above mixed solution at 110°C for 16 hours, and then recrystallize at room temperature to obtain the desired sulfide ionic liquid b.

[0075] Select columnar activated carbon as t...

Embodiment 3

[0079] Select columnar activated carbon as the carrier, its particle size is 40 mesh, the ash content is 3.0wt%, and the specific surface area is 950m 2 / g, pore volume 0.6mL / g, and treated with 300ml of 10wt% hydrochloric acid at 25°C for 3h. The treated carrier was washed with deionized water until neutral, dried at 110° C. for 12 hours, and then ready for use.

[0080] Synthesis of sulfide ionic liquid A:

[0081] Mix the ionic liquid 1-butyl-3-methylimidazolium chloride and sulfur powder at a mass ratio of 1:0.5, stir in a water bath at 40°C for 10 minutes, then add acetonitrile solution, dissolve, and stir at 40°C for 12 hours, Stir the above mixture evenly, then filter to remove unreacted sulfur powder, dry the obtained filtrate at 110°C, then dissolve the sample obtained after drying in dichloromethane, add an appropriate amount of Ionized water and sodium bicarbonate solution were used to further remove impurities in the solution. Finally, the above mixed solution wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com