Preparation method of efficient scale-inhibiting corrosion-inhibiting low-phosphorous water quality stabilizer

A water quality stabilizer, anti-scale and corrosion technology, applied in the direction of scale removal and water softening, chemical instruments and methods, natural water treatment, etc., can solve the discharge of phosphorus-containing substances, environmental pollution, and the effect of scale and corrosion inhibition is not obvious, etc. problems, to achieve the effect of preventing corrosion, improving scale and corrosion inhibition performance, excellent calcium carbonate scale and calcium sulfate scale resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

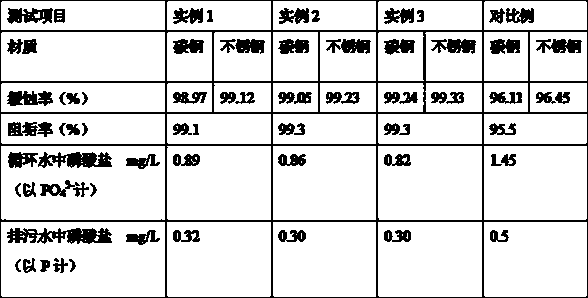

Examples

example 1

[0024] Weigh 30g of L-aspartic acid and put it into a beaker with 6mL of sulfuric acid solution with a mass fraction of 35%, and conduct a polycondensation reaction at 180°C for 35min to obtain a polycondensation product, then add 7mL of 20% sulfuric acid to the polycondensation product Ammonia water, 4mL ethanolamine, 3mL phosphorus trichloride and 2mL formaldehyde solution with a mass fraction of 37%, after the heat preservation reaction was continued for 20min, the modified self-made polyaspartic acid was obtained. Weighed 20g limes, peeled and chopped, and then put into Squeeze the juice in a juicer with 30mL of deionized water for 6 minutes to obtain a mixed solution containing citric acid, mix the mixed solution containing citric acid, ethylene glycol and 1,2-xylene at a volume ratio of 3:2:1 Place in a four-necked flask equipped with a stirring bar, a reflux condenser and a thermometer, stir for 2 hours under nitrogen protection and a temperature of 80°C, then add 2% n-b...

example 2

[0026] Weigh 40g of L-aspartic acid and put it into a beaker with 7mL of sulfuric acid solution with a mass fraction of 35%, and conduct a polycondensation reaction at 230°C for 48min to obtain a polycondensation product, then add 8mL of 20% sulfuric acid to the polycondensation product In ammonia water, 5mL ethanolamine, 4mL phosphorus trichloride and 3mL formaldehyde solution with a mass fraction of 37%, after continuing the heat preservation reaction for 25min, the modified self-made polyaspartic acid was obtained, weighed 25g limes, peeled and chopped, and then put into Squeeze the juice in a juicer with 40mL deionized water for 7 minutes to obtain a mixed solution containing citric acid, mix the mixed solution containing citric acid, ethylene glycol and 1,2-xylene at a volume ratio of 3:2:1 Place in a four-neck flask equipped with a stirring bar, a reflux condenser and a thermometer, stir for 3 hours under nitrogen protection and a temperature of 90°C, then add 2% n-butano...

example 3

[0028]Weigh 50g of L-aspartic acid and put it into a beaker with 8mL of sulfuric acid solution with a mass fraction of 35%, and conduct a polycondensation reaction at 280°C for 60min to obtain a polycondensation product, then add 9mL of 20% sulfuric acid to the polycondensation product Ammonia water, 6mL ethanolamine, 5mL phosphorus trichloride and 4mL formaldehyde solution with a mass fraction of 37% were added, and the heat preservation reaction was continued for 30 minutes to obtain modified self-made polyaspartic acid. Weighed 30g of limes, peeled and chopped, and then put into Squeeze the juice in a juicer with 50 mL of deionized water for 8 minutes to obtain a mixed solution containing citric acid, mix the mixed solution containing citric acid, ethylene glycol and 1,2-xylene at a volume ratio of 3:2:1 Place in a four-necked flask equipped with a stirring bar, a reflux condenser and a thermometer, stir for 4 hours under nitrogen protection and a temperature of 100°C, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com