A kind of refining method of wood vinegar and its application

A refining method and technology of wood vinegar liquid, applied in the field of biomass resource utilization, can solve the problems of high cost, poor refining effect, long time consumption, etc., and achieve the effects of short time consumption, simple composition and low refining cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The refining method of the wood vinegar provided by the present embodiment may further comprise the steps:

[0024] A demulsifier was prepared, and its raw materials were as follows: 2 g of the acetal product of n-butyraldehyde and propylene glycol, 135 g of glycerol, 6 g of cyclohexane, 0.4 g of polyvinyl alcohol, and 6 g of AE8051 dry agent.

[0025] Among them, AE8051 is a block polymer composed of aliphatic amine, ethylene oxide, and propylene oxide.

[0026] Take 1000kg of crude wood vinegar, add 10g of the demulsifier prepared above into it at room temperature, mix well, let it settle for 30min, remove the obtained oil phase, and obtain refined wood vinegar.

[0027] The refined wood vinegar obtained in the present embodiment is clear and translucent.

Embodiment 2

[0029] The refining method of the wood vinegar provided by the present embodiment may further comprise the steps:

[0030] A demulsifier was prepared, and its raw material composition was: 3.5 g of acetal product of p-hydroxybenzaldehyde and ethylene glycol, 60 g of polyglycerol, 10 g of cyclohexane, 2 g of polyvinyl alcohol, and 4 g of BP2040 dry agent.

[0031] Take crude wood vinegar, add 50ppm of the above-mentioned demulsifier to it at room temperature, stir for 3 minutes, then let it settle for 20 minutes, remove the obtained oil phase, and obtain refined wood vinegar.

Embodiment 3

[0033] The refining method of the wood vinegar provided by the present embodiment may further comprise the steps:

[0034] Take 1000kg of crude wood vinegar, add 100g of demulsifier to it at room temperature, stir for 2 minutes, then let it settle until the phase separation is complete, remove the obtained oil phase, and obtain refined wood vinegar.

[0035] The raw material composition of the demulsifier used in this example is: 3 g of the acetal product of benzaldehyde and ethylene glycol, 83 g of glycerol, 10.4 g of toluene, 3.6 g of polyvinyl alcohol, and 5 g of BP2040 dry agent.

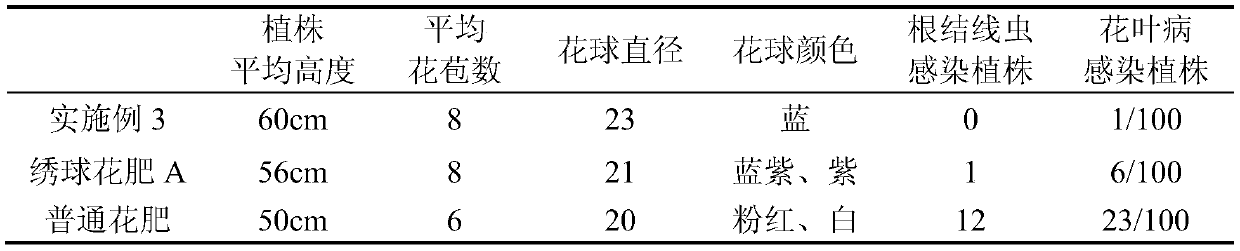

[0036] Get 6kg of refined wood vinegar, 1.5kg of urea, 80g of magnesium sulfate, 0.7kg of diammonium phosphate, 0.7kg of potassium chloride, and 0.8kg of aluminum sulfate obtained in the present embodiment to be mixed with special compound liquid fertilizer for hydrangea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com