Gold nanoparticle/reduced graphene oxide composite electrode, and preparation and application thereof

A gold nanoparticle and graphene composite technology, which is applied in the cross field of electroanalytical chemistry and chromatography technology, can solve the problems of easy falling off of modified materials, affecting electrode life and reproducibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

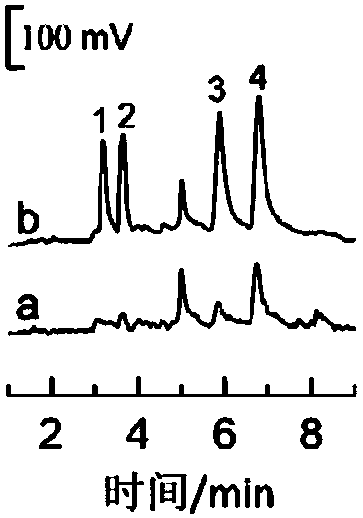

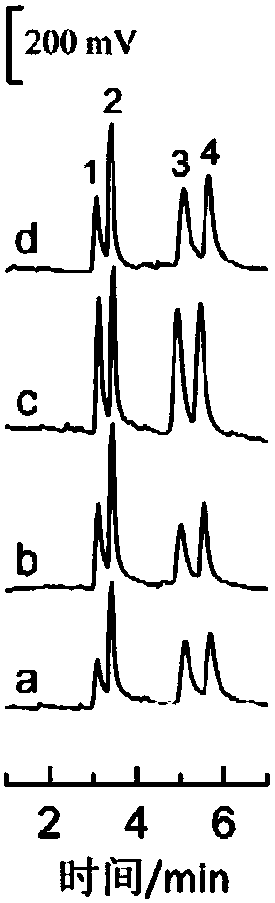

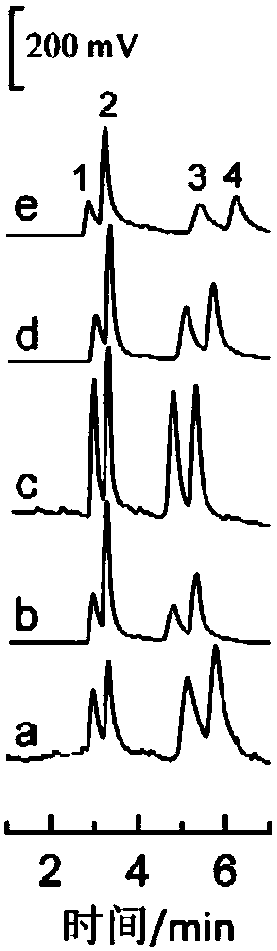

[0069] Gold Nanoparticles / Reduced Graphene Oxide Composite Electrode Applied to the Working Electrode of Chip-Free Electrophoresis-Amperometric Detection System

[0070] Weigh 2 g of flake graphite and 1 g of sodium nitrate into a 500 ml three-neck flask, slowly add 80 ml of concentrated sulfuric acid with a mass fraction of 98%, and mechanically stir for 5 minutes at room temperature until a black suspension appears. After slowly adding 15 g of potassium permanganate ground to pieces, the mixture was mechanically stirred in a water bath at 38°C for 24 hours, and it turned into a gray-brown viscous substance. Stop heating, slowly add 300 milliliters of deionized water to the product, and add an appropriate amount of hydrogen peroxide to neutralize excess potassium permanganate to obtain egg yellow colloid. Suction filtration under reduced pressure, followed by washing with 1 mol / L hydrochloric acid and deionized water, and vacuum drying at 50°C after washing to obtain graphene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com