Preparation method of PEO based polymer diaphragm and preparation method of primary battery with PEO based polymer diaphragm

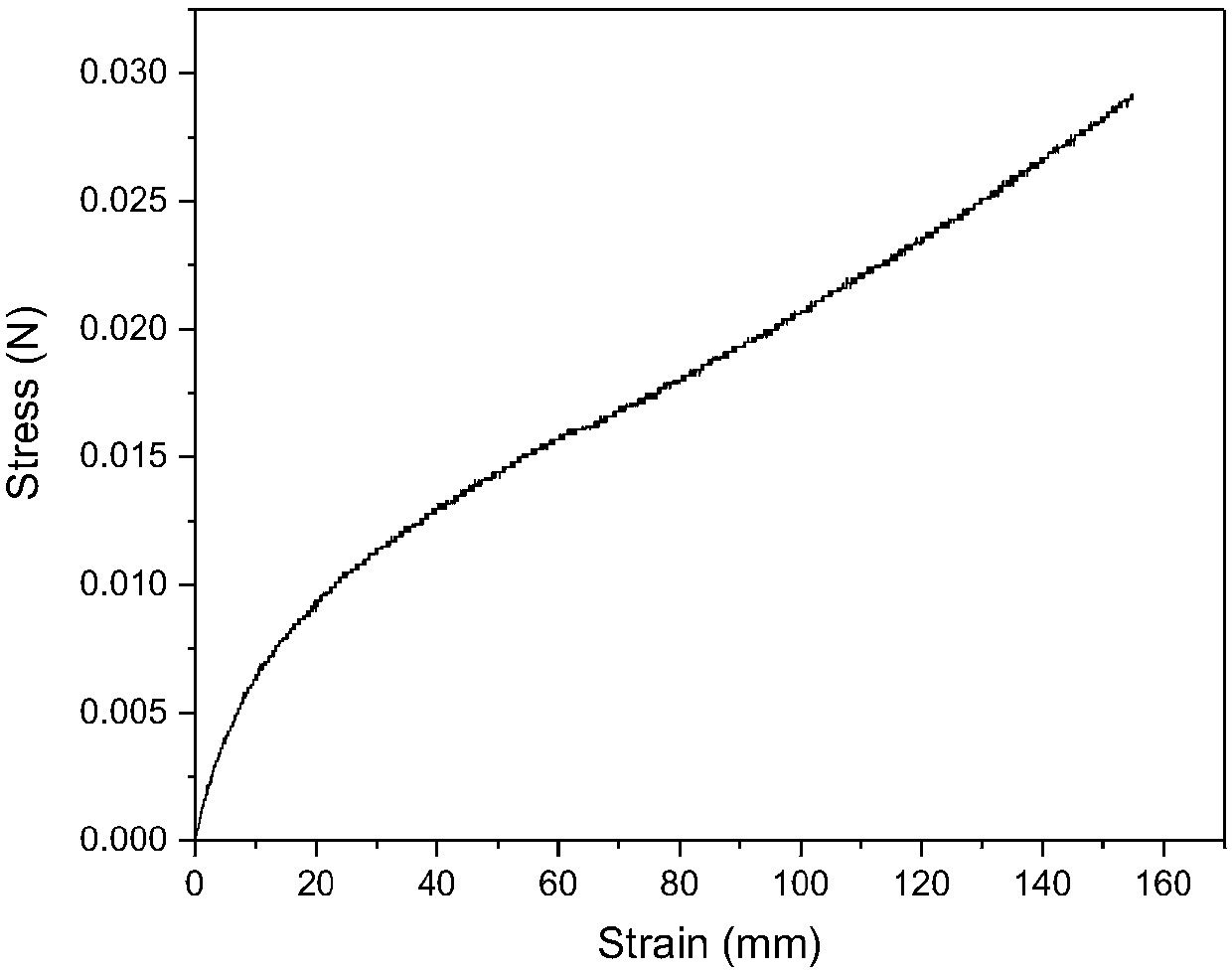

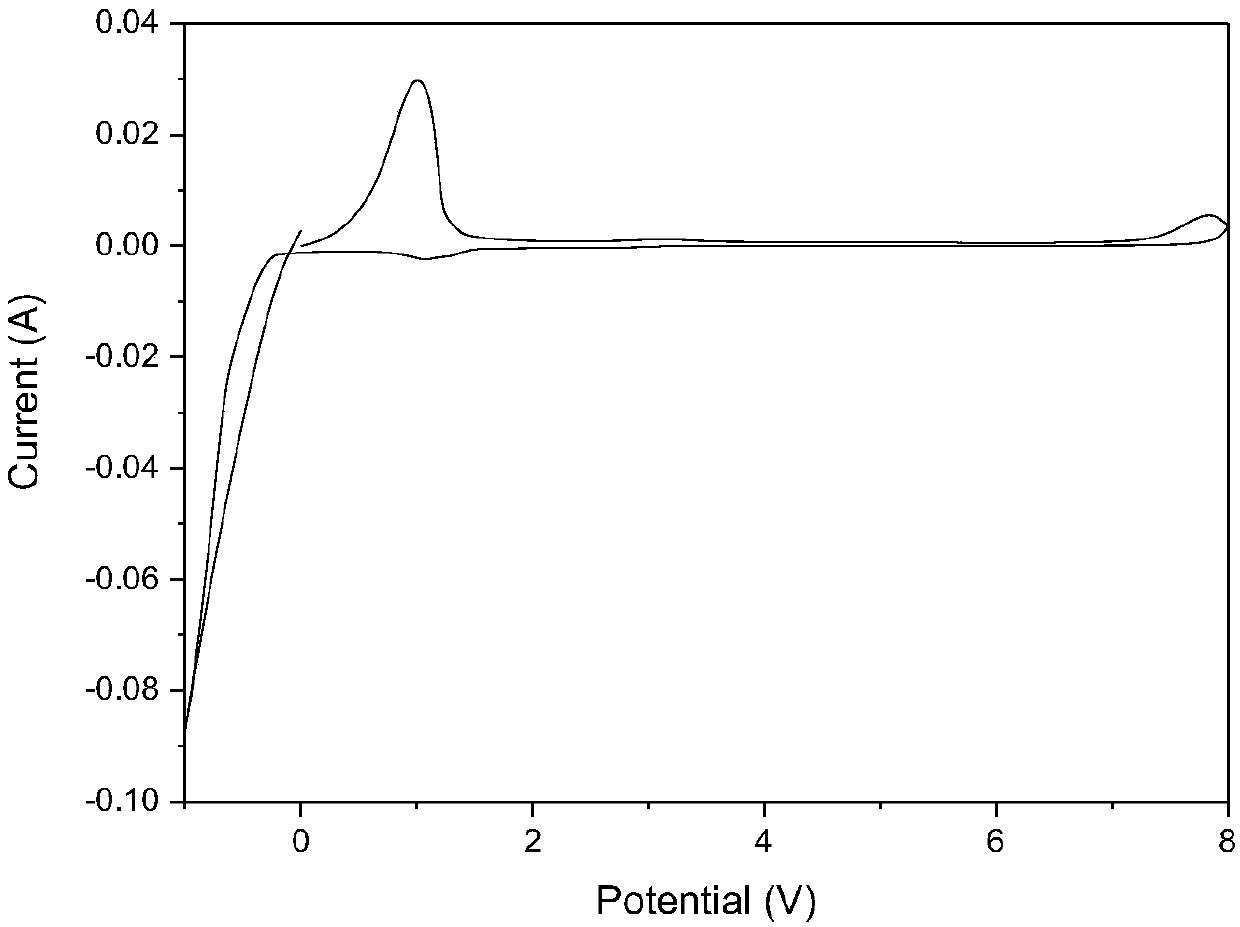

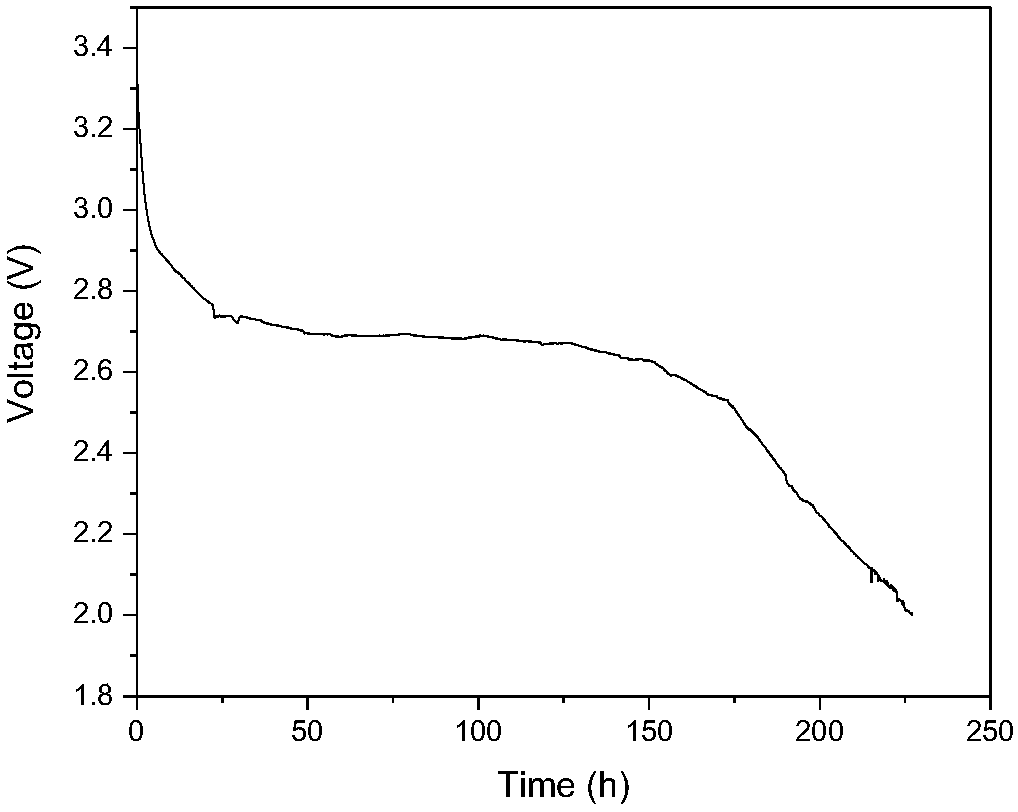

A polymer and separator technology, applied in the field of lithium-ion energy storage batteries, can solve the problems affecting the safety performance of the battery, short circuit of positive and negative electrodes, poor mechanical properties, etc., and achieve the effects of good mechanical properties, stable discharge voltage, and excellent electrical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The steps are:

[0042] a. Dissolve 0.005 mol of polyethylene glycol PEG with a molecular weight of 2000 and 0.011 mol of isocyanatopropyl triethoxysilane (according to the functional group -OH, -NCO molar ratio 1:1.1) in tetrahydrofuran, under a nitrogen atmosphere at 60 ° C After reacting for 12 hours, the purification of the product is called: adding n-hexane with a ratio of 1:1 to the original solvent to the product, then performing suction filtration, washing twice with n-hexane, and then suction filtration, finally collecting the solid and placing it at 40°C Vacuum drying in oven to obtain intermediate product A;

[0043]b. Mix 0.005mol of intermediate product A with 30% mass fraction of silica hydrosol, wherein the molar ratio of intermediate product A to silica hydrosol is 2:1, and react at 80°C under nitrogen atmosphere After 48 hours, the product was purified: partly evaporated the solvent, then added a mixed solution of n-hexane and chloroform with a volume ...

Embodiment 2

[0047] The steps are:

[0048] a. Dissolve 0.005 mol of polyethylene glycol PEG with a molecular weight of 2000 and 0.0105 mol of isocyanatopropyltriethoxysilane (according to the functional group -OH, -NCO molar ratio 1:1.05) in tetrahydrofuran, 62 ° C under nitrogen atmosphere After reacting for 13 hours, the purification process of the product is called: adding n-hexane with a ratio of 1:1 to the original solvent to the product, then performing suction filtration, washing twice with n-hexane, and then suction filtration, finally collecting the solid and placing it at 40°C Vacuum drying in oven to obtain intermediate product A;

[0049] b. Mix 0.005mol of intermediate product A with 30% mass fraction of silica hydrosol, wherein the molar ratio of intermediate product A to silica hydrosol is 2:1.1, and react at 82°C under nitrogen atmosphere After 50 hours, the product was purified: partly evaporated the solvent, then added a mixed solution of n-hexane and chloroform with a ...

Embodiment 3

[0053] The steps are:

[0054] a. Dissolve 0.005 mol of polyethylene glycol PEG with a molecular weight of 2000 and 0.012 mol of isocyanatopropyltriethoxysilane (according to the functional group -OH, -NCO molar ratio 1:1.2) in tetrahydrofuran, under a nitrogen atmosphere at 65 ° C Reaction for 14 hours, product purification is called: add n-hexane with a ratio of 1:1 to the original solvent to the product, then carry out suction filtration operation, wash twice with n-hexane, and then suction filtration, finally collect the solid and store it at 40°C Vacuum drying in oven to obtain intermediate product A;

[0055] b. Mix 0.005mol intermediate product A with 25% mass fraction of silica hydrosol, wherein the molar ratio of intermediate product A to silica hydrosol is 2:1.2, and react at 85°C under nitrogen atmosphere After 52 hours, the product was purified: partly evaporated the solvent, then added a mixed solution of n-hexane and chloroform with a volume ratio of 1:1, centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com