Feed additive for increasing disease resistance of cows and feeding device

A feed additive and disease resistance technology, which is applied in the field of feed additives and feeding devices for increasing disease resistance of dairy cows, can solve the problems of inability to meet needs, difficult to achieve, and single variety, and achieve good social and ecological environmental benefits. Helps detoxification, promotes decomposition, digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

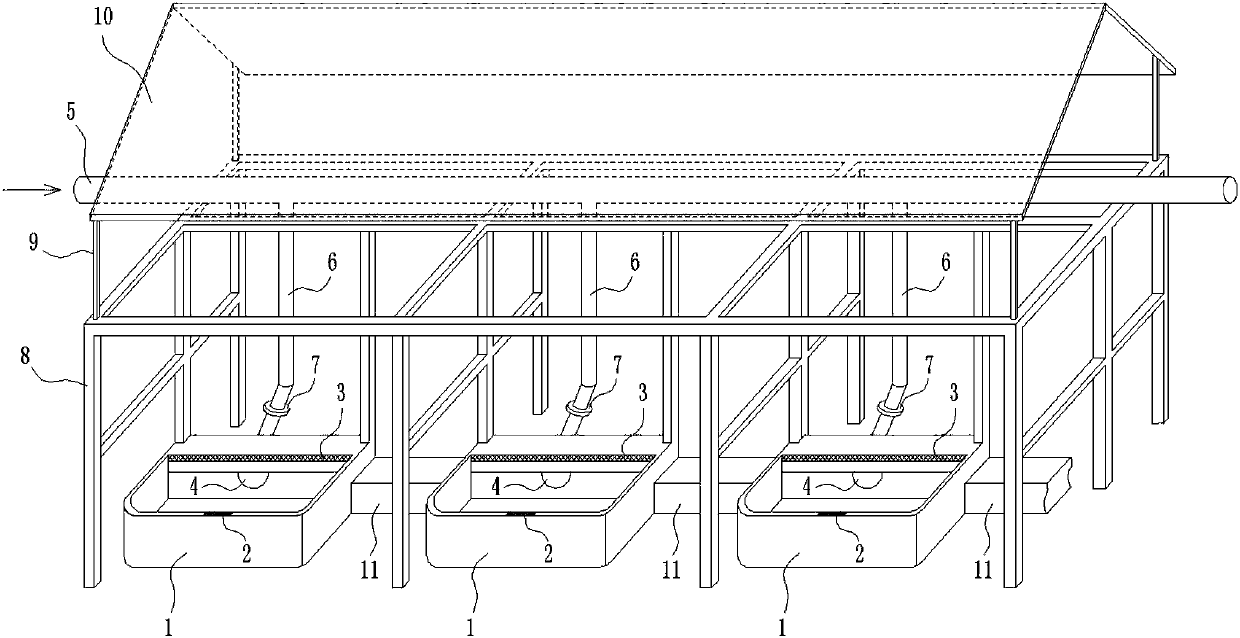

Image

Examples

Embodiment 1

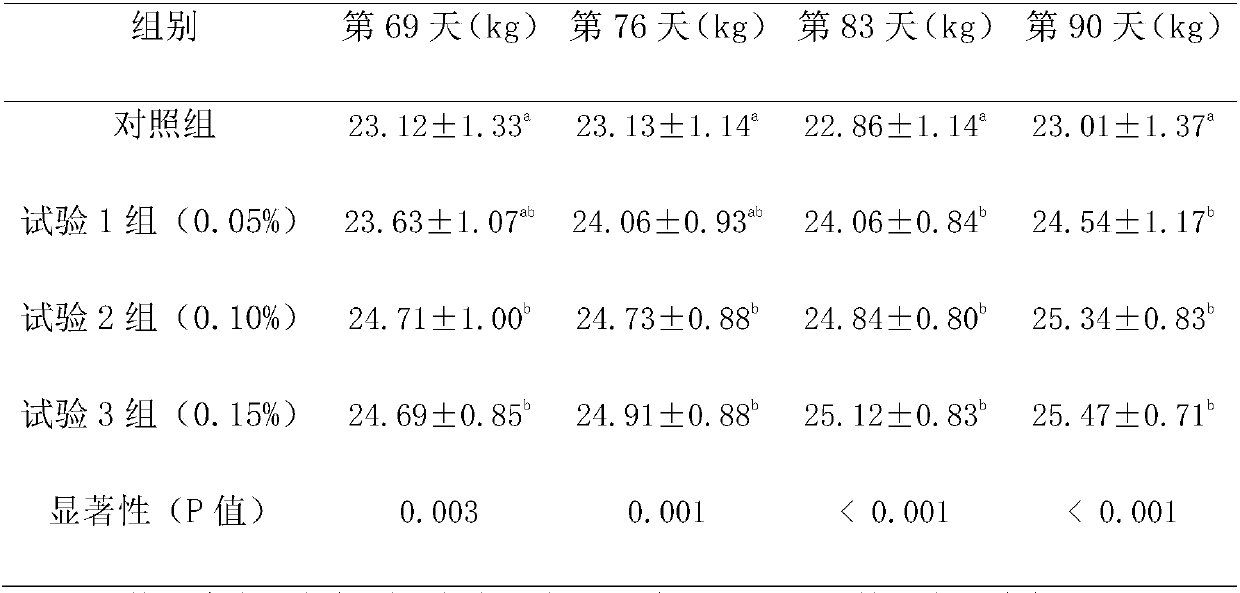

[0038] A feed additive for increasing disease resistance of dairy cows, comprising the following components by weight: 50 parts of almond skin, 32 parts of walnut oil residue, 21 parts of tung fruit residue, 18 parts of black corncob powder, 2 parts of Bacillus licheniformis, 3 parts of butyric acid bacteria, 0.1 part of plant enzyme agent, 0.5 part of γ-aminobutyric acid.

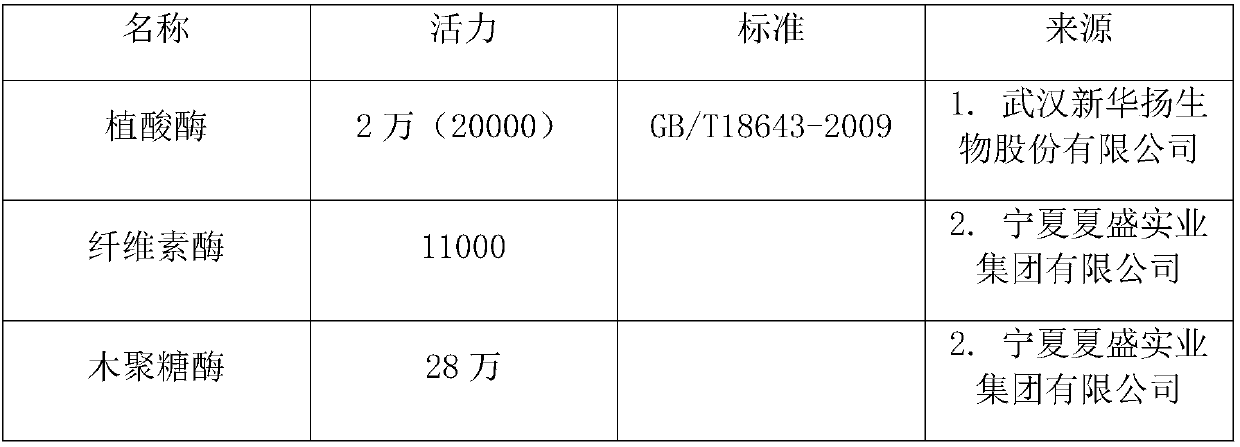

[0039] Wherein, the oil content in the walnut oil dregs is 5%; the particle diameter of the black corncob powder is 130 mesh; It is prepared by fermentation. The specific fermentation method is: mix pomegranate peel and potato peel at a weight ratio of 1:3, wash twice with 3% sodium bicarbonate solution, crush to 40 mesh, add 2 times the weight of water, and adjust the pH 5.3, add 1.3% enzyme bacteria, add 1.2% nitrogen source and carbon source respectively, ferment for 5 days at 30°C, and the product after fermentation is filtered, purified and dehydrated to obtain the plant enzyme agent.

[0040] The ab...

Embodiment 2

[0042] A feed additive for increasing disease resistance of dairy cows, comprising the following components by weight: 66 parts of almond skin, 43 parts of walnut oil residue, 23 parts of tung fruit residue, 24 parts of black corncob powder, 3.5 parts of Bacillus licheniformis, 6 parts of butyric acid bacteria, 2 parts of plant enzymes, 1.5 parts of γ-aminobutyric acid.

[0043] Wherein, the oil content in the walnut oil dregs is 6.5%; the particle diameter of the black corncob powder is 170 mesh; It is prepared by fermentation. The specific fermentation method is: mix pomegranate peel and potato peel at a weight ratio of 1:5, wash twice with 3% sodium bicarbonate solution, crush to 40 mesh, add 3.5 times the weight of water, and adjust the pH 6.0, add 2.6% enzyme bacteria, add 2.4% nitrogen source and carbon source respectively, ferment at 30°C for 6 days, and the product after fermentation is filtered, purified and dehydrated to obtain the plant enzyme agent.

[0044] The a...

Embodiment 3

[0046] A feed additive for increasing disease resistance of dairy cows, comprising the following components by weight: 82 parts of almond skin, 55 parts of walnut oil residue, 25 parts of tung fruit residue, 30 parts of black corncob powder, 5 parts of Bacillus licheniformis, 9 parts of butyric acid bacteria, 4 parts of plant enzymes, 2.5 parts of γ-aminobutyric acid.

[0047] Wherein, the oil content in the walnut oil dregs is 8%; the particle diameter of the black corncob powder is 200 mesh; It is prepared by fermentation. The specific fermentation method is: mix pomegranate peel and potato peel at a weight ratio of 1:8, wash with 3% sodium bicarbonate solution for 3 times, crush to 40 mesh, add 5 times the weight of water, and adjust the pH 6.5, add 4% enzyme bacteria, add 3.5% nitrogen source and carbon source respectively, ferment for 7 days at 30°C, and the product after fermentation is filtered, purified and dehydrated to obtain the plant enzyme agent.

[0048] The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com