Barium strontium titanate dielectric material for microwave tuning devices

A technology of barium strontium titanate and a dielectric material is applied in the field of barium strontium titanate dielectric materials for microwave tuning devices, and can solve the problems of dielectric tunability and other electrical properties decline, high dielectric loss, limiting the application of BST materials, etc. , to achieve the effect of improving dielectric properties, high dielectric constant, and cost controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one of the present invention is:

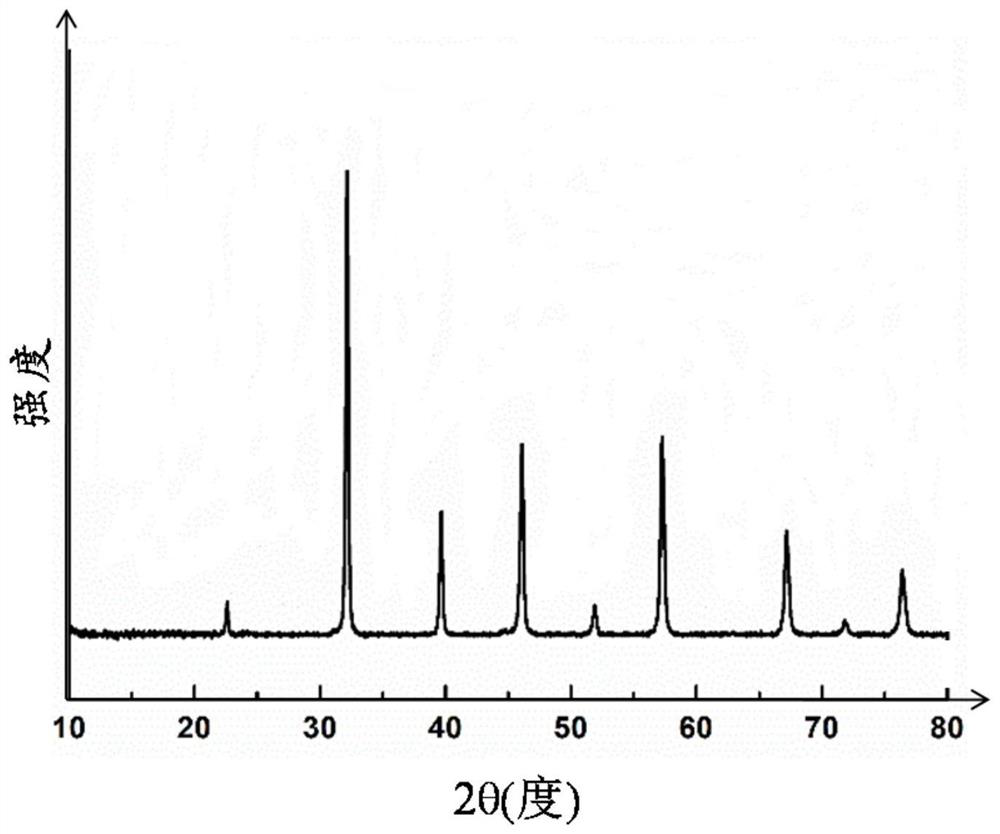

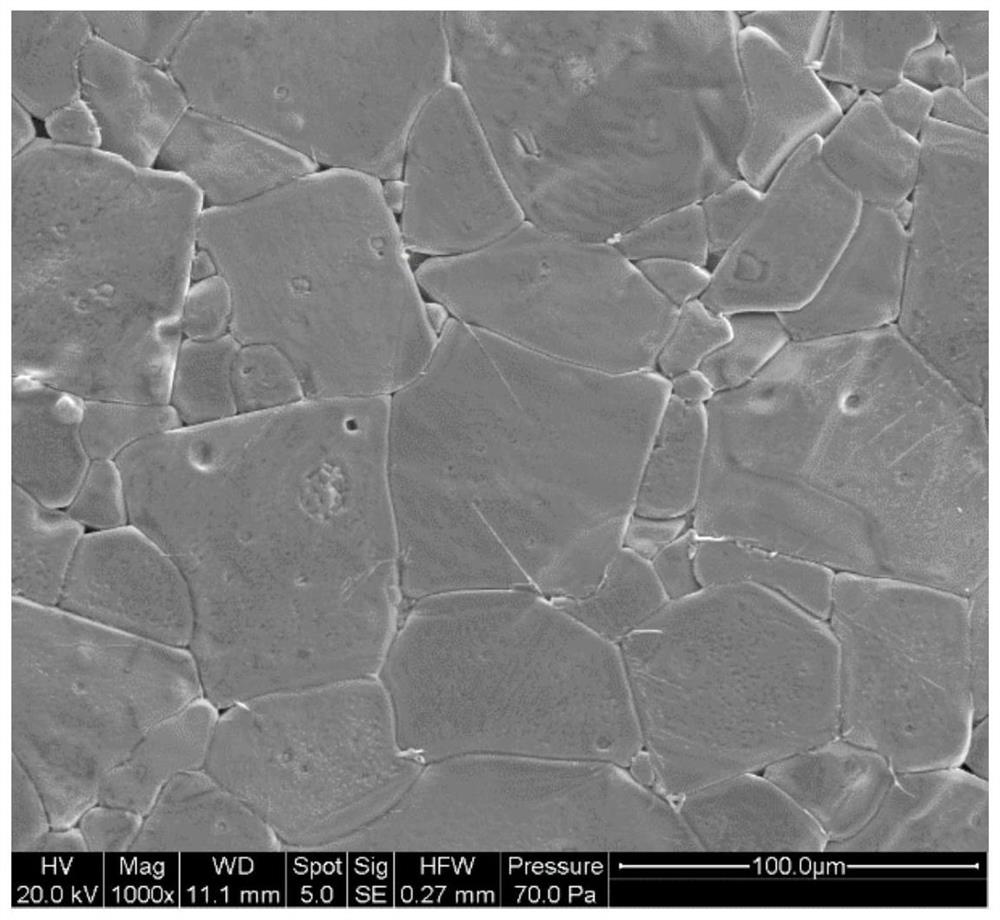

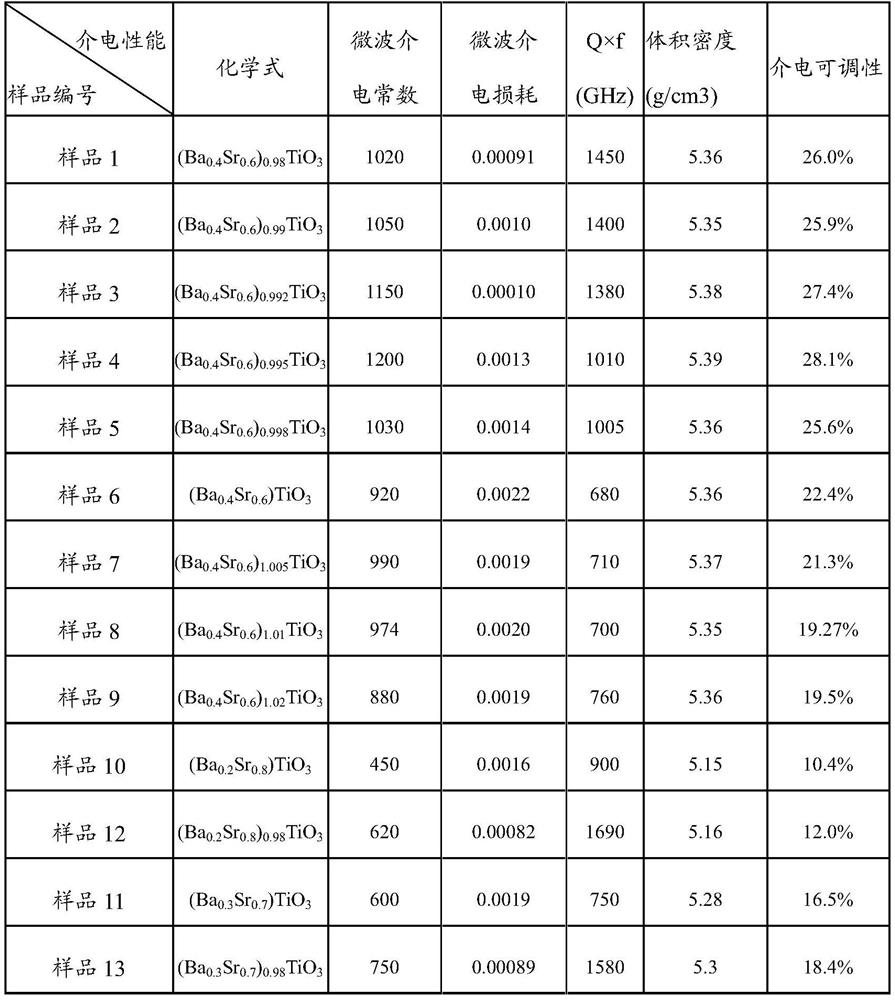

[0025] A kind of strontium barium titanate dielectric material for microwave tuning device, the chemical general formula of described strontium barium titanate dielectric material is (Ba x Sr 1-x ) 1+δ TiO 3 , wherein x=0.2~0.4, δ=-0.02~0.02. Preferably, x=0.4, δ=-0.02˜-0.002. figure 1 Be the XRD collection of illustrative plates of the BST material of the present embodiment, from figure 1 It can be seen that the diffraction peak around 45° is in the shape of a single peak, and there is no phenomenon of peak splitting, indicating that the BST material is a single cubic perovskite structure. figure 2 Be the SEM picture of the BST material of the present embodiment, by figure 2 It can be seen that the BST material has a single grain shape, the grain growth is intact, and no obvious impurity phase is observed inside the grain and at the grain boundary.

Embodiment 2

[0027] Embodiment 2 of the present invention is the preparation method of BST material, comprising:

[0028] (1) with (Ba 0.4 Sr 0.6 ) 0.98 TiO 3 The chemical formula composition weighs BaTiO respectively 3 (purity 99.5%) and SrTiO 3 (purity 99.5%) raw material.

[0029] (2) Using absolute ethanol as the ball milling medium, add the weighed raw materials into a ball milling tank, and adopt horizontal wet ball milling process to mix and ball mill for 24 hours. After discharge, it is dried in an oven at 80°C, and then pre-fired in a muffle furnace at 1150°C for 2 hours to obtain BST ceramic powder.

[0030] (3) in the BST ceramic powder that obtains in step (2), add the polyvinyl alcohol (PVA) aqueous solution that accounts for powder quality 2wt% and carry out granulation, after crossing 80 mesh sieves, under the uniaxial pressure of 175MPa, make Get BST ceramic green body. Then the ceramic green body was kept at 600°C for 2 hours for debinding, and then sintered at 140...

Embodiment 3

[0032] Embodiment 3 of the present invention is the preparation method of BST material, comprises:

[0033] (1) with (Ba 0.4 Sr 0.6 ) 0.99 TiO 3 The chemical formula composition weighs BaTiO respectively 3 (purity 99.5%) and SrTiO 3 (purity 99.5%) raw material.

[0034] (2) Using absolute ethanol as the ball milling medium, add the weighed raw materials into a ball milling tank, and adopt horizontal wet ball milling process to mix and ball mill for 24 hours. After discharge, it is dried in an oven at 80°C, and then pre-fired in a muffle furnace at 1150°C for 2 hours to obtain BST ceramic powder.

[0035] (3) in the BST ceramic powder that obtains in step (2), add the polyvinyl alcohol (PVA) aqueous solution that accounts for powder quality 2wt% and carry out granulation, after crossing 80 mesh sieves, under the uniaxial pressure of 175MPa, make Get BST ceramic green body. Then the ceramic green body was kept at 600°C for 2 hours for debinding, and then sintered at 1400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com