A method for enzymatically synthesizing phytosterol esters in an ionic liquid system

A technology for phytosterol esters and ionic liquids, which is applied in the field of enzymatic synthesis of phytosterol esters, can solve the problems of lowering product quality, easily polluting the environment, poor safety, etc., and achieves improved conversion rate, wide liquid range and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Get raw material phytosterol 1.61g (the total phytosterol content exceeds 90%), oleic acid 0.84g, add different ionic liquids 0.98g (comprising [BMIM][Tf 2 N], [HMIM][Tf 2 N], [BMMIM] [Tf 2 N], [HO(CH 2 ) 2 MIM][Tf 2 N], [MeO(CH 2 ) 2 MIM][NTf 2 ], [OMIM][PF 6 ], [C 10 MIM][PF 6 ], [BMIM][Tf 2 N]), dissolve phytosterols and fatty acids, then add immobilized enzyme Lipozyme 453, the reaction temperature is 70°C, the stirring speed is 500rpm, the reaction time is 24h, and the sterols are extracted with a certain amount of n-hexane / diethyl ether (4:1) mixed solution The ester is used to remove ionic liquid and lipase, after centrifugation at 12000rpm for 6min, the supernatant liquid is blown with nitrogen, and the reaction product is obtained after removing the organic solvent.

[0034] The external standard method was used for quantification, and the acid-base titration method was used to detect the change of fatty acid content in the reaction system. Esterifi...

Embodiment 2

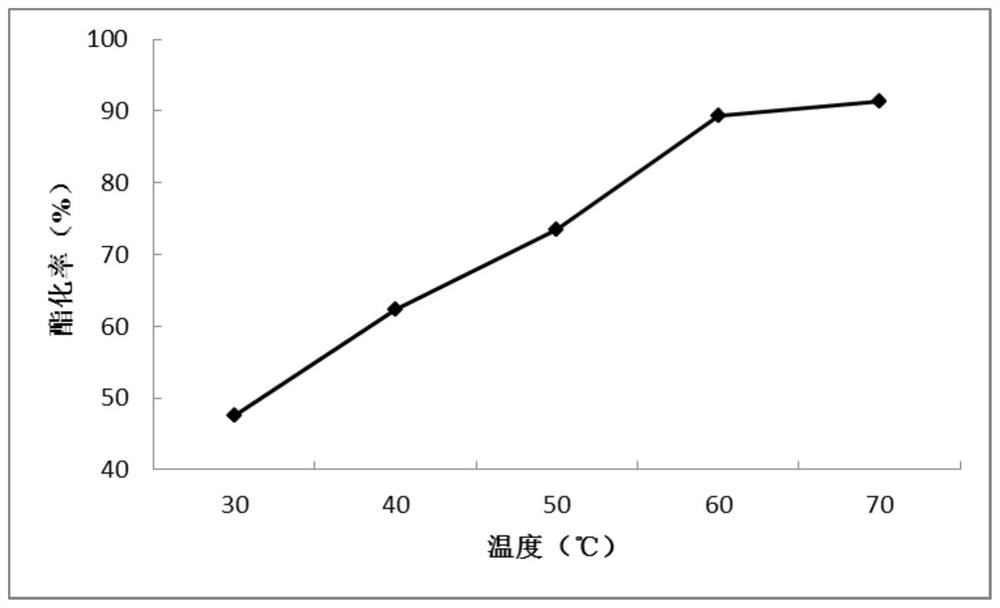

[0038] Get raw material phytosterol 1.61g (the total plant sterol content exceeds 90%), oleic acid 0.84g adds ionic liquid [MeO(CH 2 ) 2 MIM][NTf 2 ]0.98g, dissolve phytosterols and fatty acids, then add immobilized enzyme Novozym 435, the reaction temperature is 30°C, 40°C, 50°C, 60°C, 70°C, the stirring speed is 500rpm, the reaction time is 24h, with a certain amount of n-hexane A mixture of alkanes / ether (4:1) was used to extract sterol esters to remove ionic liquids and lipase, centrifuge at 12,000 rpm for 6 minutes, take the supernatant liquid and blow it with nitrogen, and remove the organic solvent to obtain the reaction product.

[0039] The external standard method was used for quantification, and the acid-base titration method was used to detect the change of fatty acid content in the reaction system. Esterification rate formula: (molar weight of fatty acid before reaction-molar weight of fatty acid after reaction) / molar weight of fatty acid before reaction×100%. ...

Embodiment 3

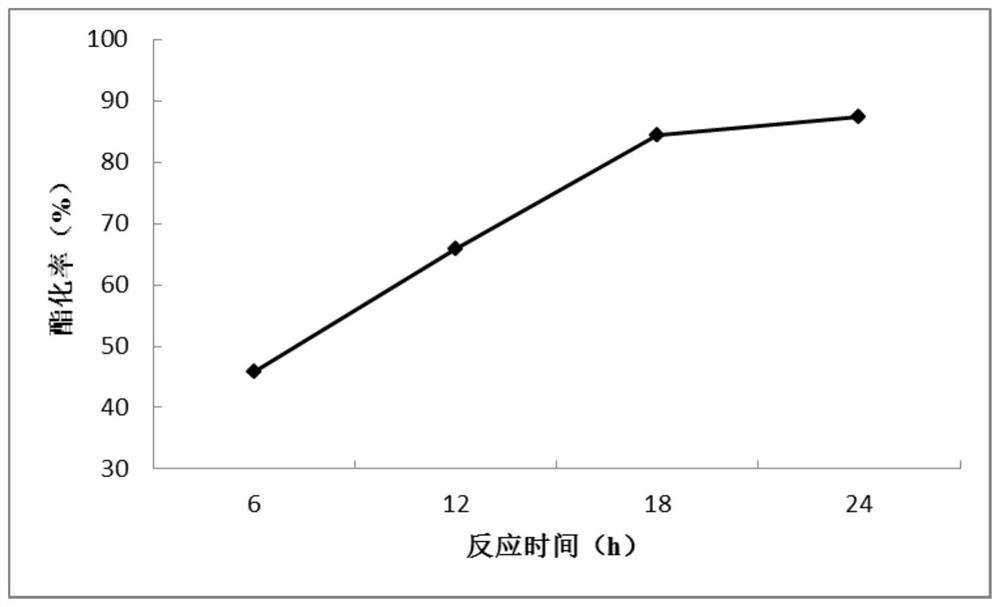

[0041] Get raw material sitosterol 1.61g (total phytosterol content exceeds 90%), oleic acid 0.84g adds ionic liquid [MeO(CH 2 ) 2 MIM][NTf 2 ] 0.98g, dissolving phytosterol and fatty acid, then adding immobilized enzyme Novozym 435, the reaction temperature is 60°C, the stirring speed is 500rpm, the reaction time is respectively 6h, 12h, 18h, 24h, with a certain amount of normal hexane / diethyl ether (4 : 1) the mixed liquid extracts sterol esters in order to remove ionic liquid and lipase, centrifuges at 12000rpm for 6min, takes the supernatant liquid nitrogen blowing, removes the organic solvent and is the reaction product.

[0042] The external standard method was used for quantification, and the acid-base titration method was used to detect the change of fatty acid content in the reaction system. Esterification rate formula: (molar weight of fatty acid before reaction-molar weight of fatty acid after reaction) / molar weight of fatty acid before reaction×100%. Refer to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com