Wheat flake drying device

A drying device and technology for cereals, which are applied in the directions of drying, dryer, drying gas arrangement, etc., can solve the problems of affecting the quality and shelf life of cereals, low heat utilization rate, and high production cost, achieving a small thermal expansion coefficient and improving drying. Efficiency, heat loss prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

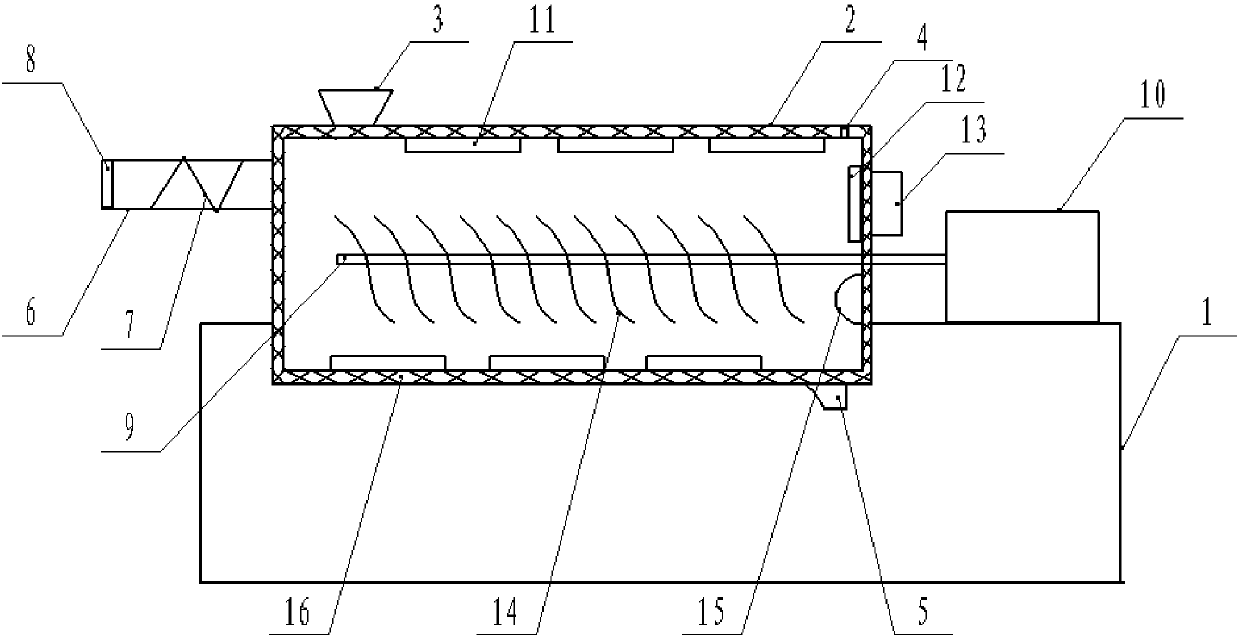

[0026] like figure 1 , a cereal drying device, comprising a bracket 1 and a drying cylinder 2 arranged on the bracket 1, the top of the drying cylinder 2 is provided with a feed port 3 and an air outlet 4, and the bottom of the drying cylinder 2 is provided with an outlet Material port 5. In this embodiment, the feeding port 3 is in the shape of a trumpet whose upper opening diameter is larger than that of the lower opening. In the cereal drying device of the present invention, there can be 3-5 air outlet holes 4, and the diameter of the air outlet holes 4 is 1.5-3.5 mm. In this embodiment, there are 5 air outlet holes 4, all of which are located in the drying cylinder. 2, and the aperture of the air outlet hole 4 is preferably 2 mm to ensure that the air flows out while preventing the oatmeal from being blown out thereupon. Simultaneously, the joint between the discharge port 5 and the side wall of the drying cylinder 2 is set on a downward slope, so as to increase the spee...

Embodiment 2

[0032] This embodiment is roughly the same as Embodiment 1, except that the drying cylinder 2 is mainly made of the following materials: 30 parts of aluminum nitride, 18 parts of nickel-cobalt alloy, 25 parts of magnesium oxide, and 10 parts of aluminum oxide , 8 parts of silicon carbide, 1 part of borax, 0.8 part of titanium dioxide, 0.1 part of antioxidant, and 0.5 part of binder. Wherein, the antioxidant is formed by mixing boron oxide and tin oxide at a ratio of 1:1, and the binder is a composition of sodium silicate and gypsum. Due to its high stability, good thermal conductivity, and small thermal expansion coefficient, aluminum nitride can be used as a good thermal shock resistant material, and its ability to resist molten metal erosion is strong, and it is also an electrical insulator. It is combined with nickel-cobalt alloys and magnesium oxide , alumina, silicon carbide, borax, titanium dioxide and other high temperature resistant, high hardness, high strength and re...

Embodiment 3

[0034] This embodiment is roughly the same as Embodiment 1, except that the drying cylinder 2 is mainly made of the following materials: 25 parts of aluminum nitride, 15 parts of nickel-cobalt alloy, 30 parts of magnesium oxide, and 5 parts of aluminum oxide , 5 parts of silicon carbide, 4 parts of borax, 0.5 part of titanium dioxide, 0.4 part of antioxidant, and 0.3 part of binder. Wherein, the antioxidant is tin oxide, and the binder is a composition of sodium silicate, clay and gypsum. Due to its high stability, good thermal conductivity, and small thermal expansion coefficient, aluminum nitride can be used as a good thermal shock resistant material, and its ability to resist molten metal erosion is strong, and it is also an electrical insulator. It is combined with nickel-cobalt alloys and magnesium oxide , alumina, silicon carbide, borax, titanium dioxide and other high temperature resistant, high hardness, high strength and refractory materials are fully combined, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com