Preparation method of naringin

A technology for naringin and grapefruit, which is applied in the field of preparation of naringin, can solve the problems of long crystallization time, complicated process operation, long time and the like, and achieves the effects of low cost, simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

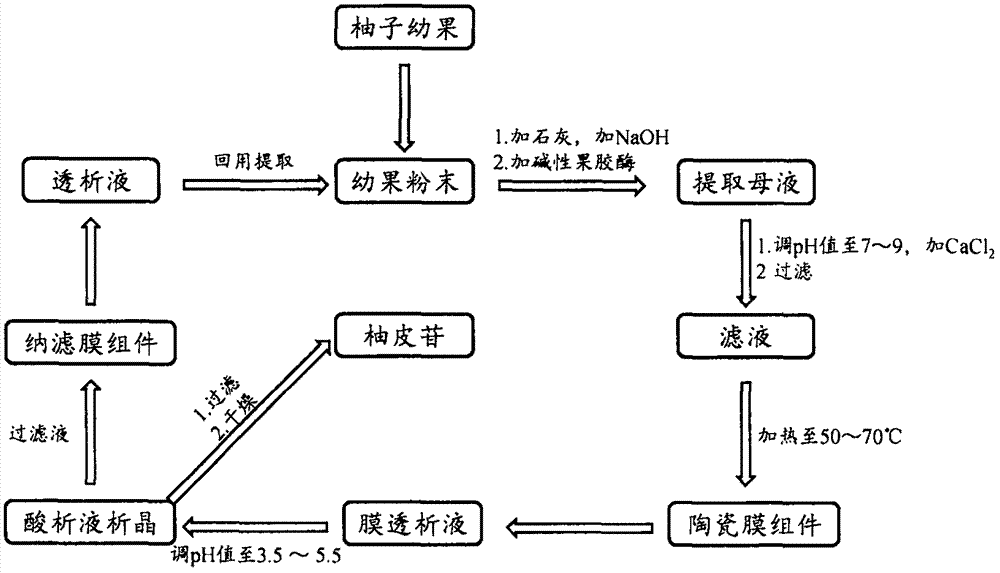

[0024] The embodiment of the present invention provides a kind of preparation method of naringin, comprises the following steps:

[0025] S1. Sieve the dried pomelo young fruit, collect the young fruit with a diameter of less than 2.5 cm, and crush it into powder, the powder particle size is not less than 50 mesh;

[0026] S2, take a certain amount of young fruit powder and place it in the extraction tank, add water in a ratio of 1: 15 to 1: 25 by mass, and add 4 to 6% lime and 10 to 12% of the young fruit powder quality at the same time. Extract with NaOH, stirring continuously during the extraction process, after 20-30 minutes of extraction, ...

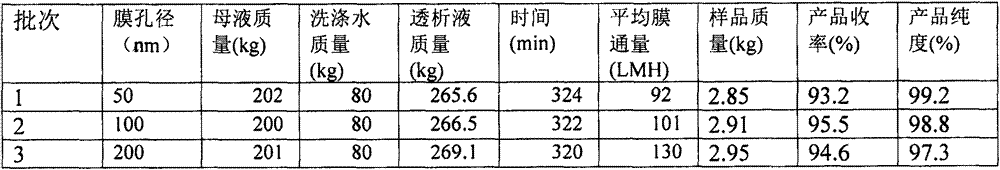

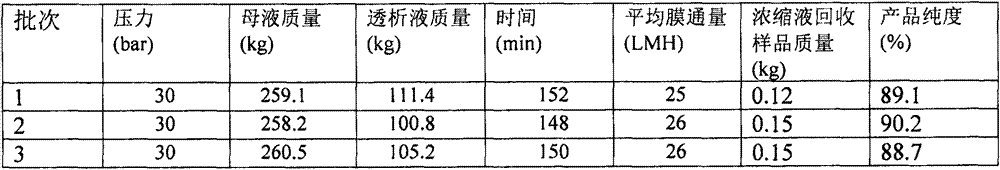

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com