Combined type fire extinguishing agent and preparation method thereof

A fire extinguishing agent, combined technology, applied in fire protection equipment and other directions, can solve the problems of eutrophication of water body, impact force of fire extinguisher, corrosion of cans, etc., to achieve the effect of low surface tension, enhanced film strength, and not easy to burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

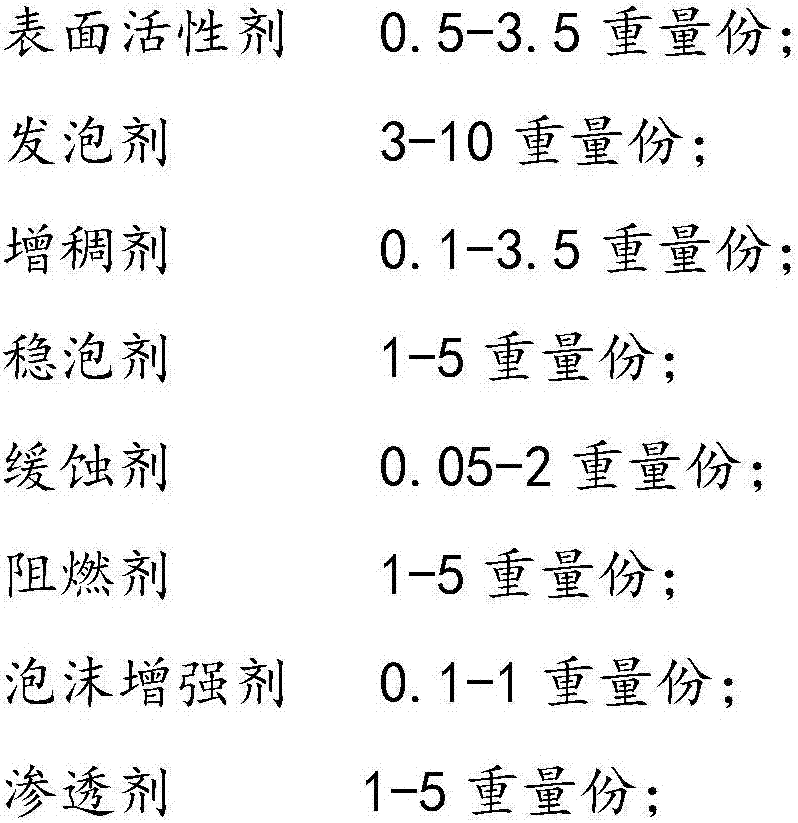

[0033] Embodiment 1 This embodiment discloses a combined fire extinguishing agent. The fire extinguishing agent is composed of a propellant and a feed liquid, and the weight ratio of the two is 10:100; the feed liquid includes the following components:

[0034]

[0035] The propellant is composed of nitrogen and carbon dioxide, and the weight ratio of the two is 55:45;

[0036] The surfactant is a mixture of perfluoroalkyl betaine, perfluoroalkyl glycoside, perfluoroalkyl polyoxyethylene ether and perfluoroalkyl phosphate in equal proportions.

[0037] The foaming agent is sodium dodecylbenzenesulfonate, dodecyl amine oxide, fatty alcohol polyoxyethylene 9 ether, fatty alcohol polyoxyethylene 7 ether, fatty alcohol polyoxyethylene 12 ether, alkyl glycoside, Coconut Fatty Amide, Sodium Oleate, Sodium Stearate, Cocamidopropyl Betaine, Sodium Xylene Sulfonate Mixed in Moderate Proportions.

[0038] The foam stabilizer is a polyether siloxane emulsion;

[0039] The corrosion ...

Embodiment 2

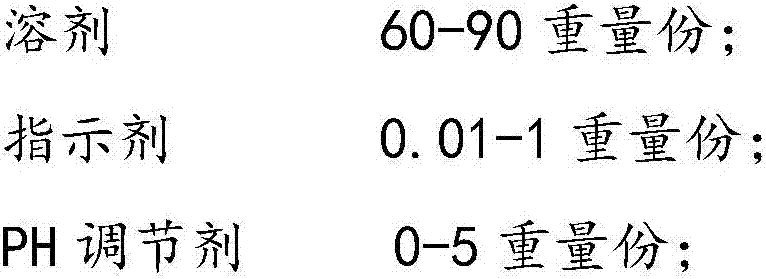

[0047] Example 2 This example discloses a combined fire extinguishing agent. The fire extinguishing agent is composed of a propellant and a feed liquid, and the weight ratio of the two is 2:100; the feed liquid includes the following components:

[0048]

[0049] The propellant is composed of nitrogen and carbon dioxide, and the weight ratio of the two is 40:60;

[0050] The surfactant is perfluoroalkylglucosamine.

[0051] The foaming agent is mixed with alkyl glucoside, coconut oil fatty amide, sodium oleate, sodium stearate, cocamidopropyl betaine and sodium xylene sulfonate in equal proportions.

[0052] The foam stabilizer is a polyether siloxane emulsion;

[0053] The corrosion inhibitor is composed of sodium silicate, sodium citrate, disodium edetate and sodium nitrite in an equal weight ratio.

[0054] Described fire retardant is potassium bicarbonate, potassium carbonate 1:3 mixes;

[0055] The thickener is a mixture of hydroxypropylmethylcellulose and hydroxyet...

Embodiment 3

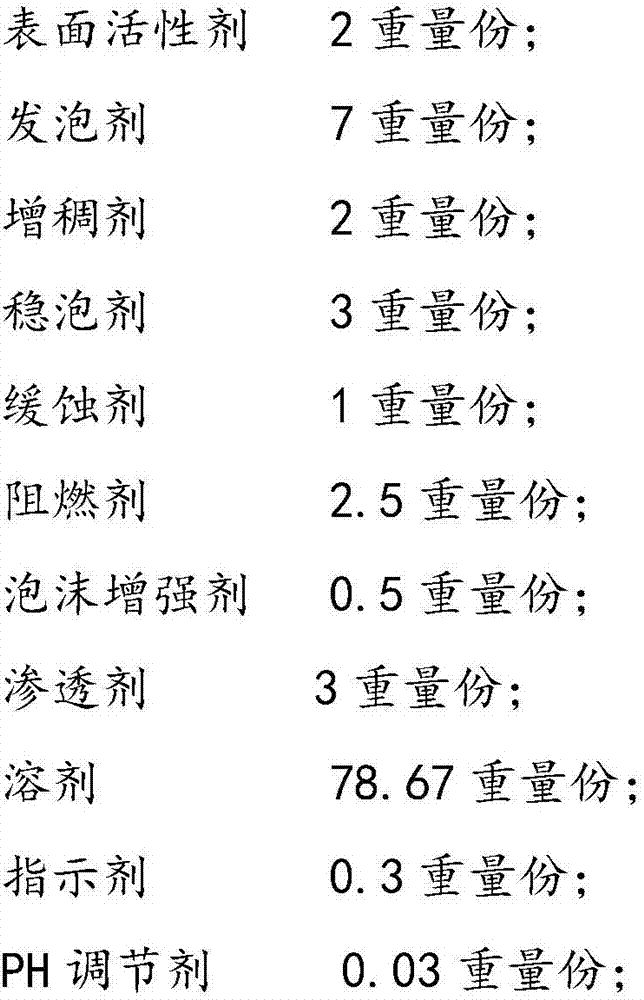

[0061] Embodiment 3 This embodiment discloses a combined fire extinguishing agent. The fire extinguishing agent is composed of a propellant and a feed liquid, and the weight ratio of the two is 15:100; the feed liquid includes the following components:

[0062]

[0063] The propellant is composed of nitrogen and carbon dioxide, and the weight ratio of the two is 70:30;

[0064] The surfactant is a mixture of perfluoroalkyl betaine, perfluoroalkyl glycoside, perfluoroalkyl polyoxyethylene ether and perfluoroalkyl phosphate in equal proportions.

[0065] The foaming agent is mixed with alkyl glucoside, coconut oil fatty amide, sodium oleate, sodium stearate, cocamidopropyl betaine and sodium xylene sulfonate in equal proportions.

[0066]The foam stabilizer is a polyether siloxane emulsion;

[0067] The corrosion inhibitor is composed of sodium silicate, sodium citrate, disodium edetate and sodium nitrite in an equal weight ratio.

[0068] Described flame retardant is sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com