N-doped TiO2-C material as well as preparation method and application thereof

A technology of nitrogen doping and tio2-c, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of harsh nitro reduction catalytic reaction conditions, low reserves of precious metal catalysts, and unfriendly environment , to achieve the effect of environmental friendliness, mild reaction conditions and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Nitrogen-doped TiO 2 -C material sample preparation

[0054] Carbon Nitride C 3 N 4 Preparation of nanosheets:

[0055] Put 40 grams of urea in the crucible, start heating from room temperature, the heating rate is 10 ° C per minute, after rising to 500 ° C, keep warm for 2 hours under the air atmosphere, naturally cool down to room temperature, and obtain carbon nitride (C 3 N 4 )Nanosheets.

[0056] Nitrogen doped TiO 2 Preparation of -C material samples:

[0057] The C obtained in step (1) 3 N 4 Disperse in 100mL ethanol solution, add structure directing agent, and 0.45mL water, add titanium source under ice bath conditions, stir for a period of time under ice bath conditions, and then centrifugally dry to obtain TiO 2 -C 3 N 4 composite nanosheets.

[0058] (3) TiO obtained in step (2) 2 -C 3 N 4 After the composite nanosheets were calcined in a nitrogen atmosphere, the temperature was naturally lowered under the protection of nitrogen ...

Embodiment 2

[0062] Example 2 Sample 1 # ~Sample 6 # representation of

[0063] Sample 1 was analyzed by X-ray powder diffraction # ~Sample 6 # XRD characterization was carried out, and the results showed that sample 1 # ~Sample 6 # TiO in 2 Anatase crystal form and / or rutile crystal form, as sample 1 # It is a typical representative, and its XRD data are shown in Table 2:

[0064] Table 2

[0065] 2θ (°)

Relative peak intensity (%)

25.4

25.7

27.5

100

36.1

47.1

41.3

22.9

44.0

75.0

48.1

8.2

54.4

74.2

56.6

17.4

62.8

24.9

64.1

13.4

69.0

22.6

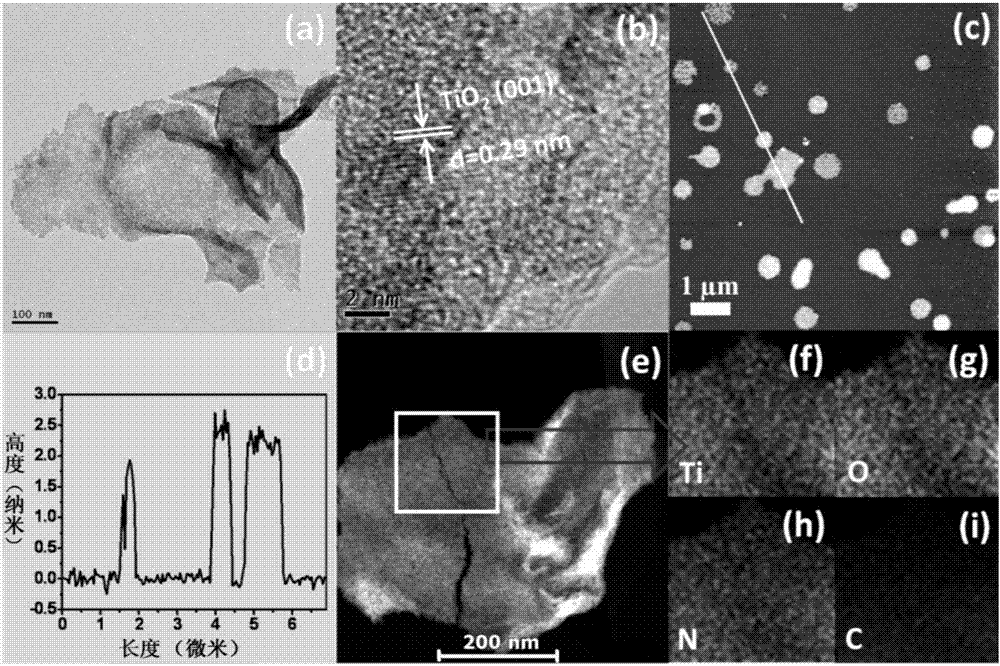

[0066] Sample 1 was examined by transmission electron microscopy # ~Sample 6 # was characterized to sample 1 # is a typical representative, and its transmission electron microscope pictures are as follows figure 1 As shown in (a), it can be seen from the figure that the obtained sample is a two-dimensional sheet structure with...

Embodiment 3

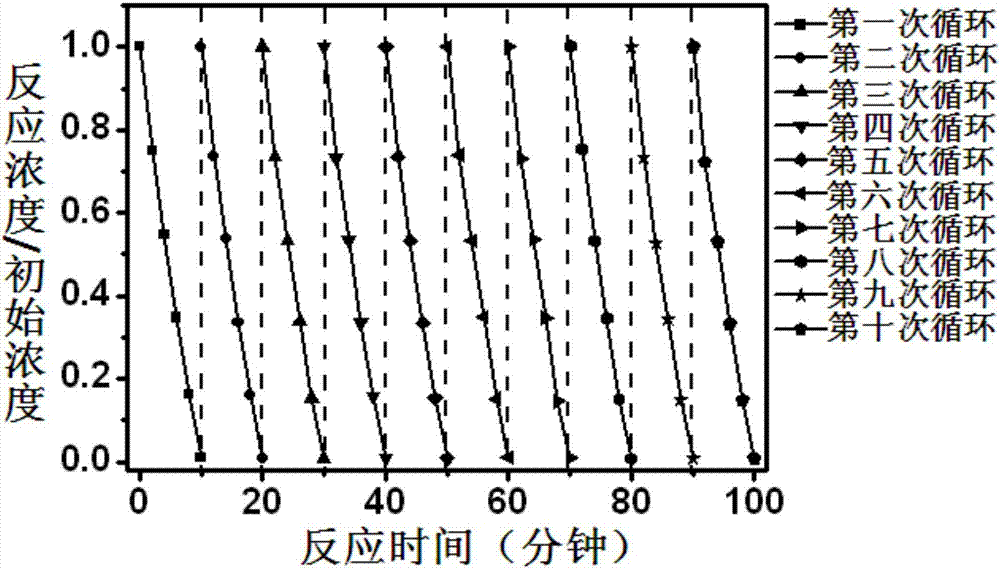

[0079] Example 3 Sample 1 # and sample D-2 # As a catalyst for the preparation of p-aminophenol from p-nitrophenol

[0080] First, dissolve 20mg of p-nitrophenol as a solid in 500mL of water, take 30mL of the above solution, and add sample 1 respectively # and sample D-2 # 10mg each as a catalyst, ultrasonically dispersed, then add 20mg sodium borohydride as a reducing agent, then the reaction system was stirred at room temperature, after 10 minutes of reaction, centrifuged to obtain the supernatant, which was the aqueous solution of p-aminophenol, and the bottom precipitate was the catalyst sample 1 # and sample D-2 # . Wash 3 times with deionized water and dry in an oven at 80°C before using again.

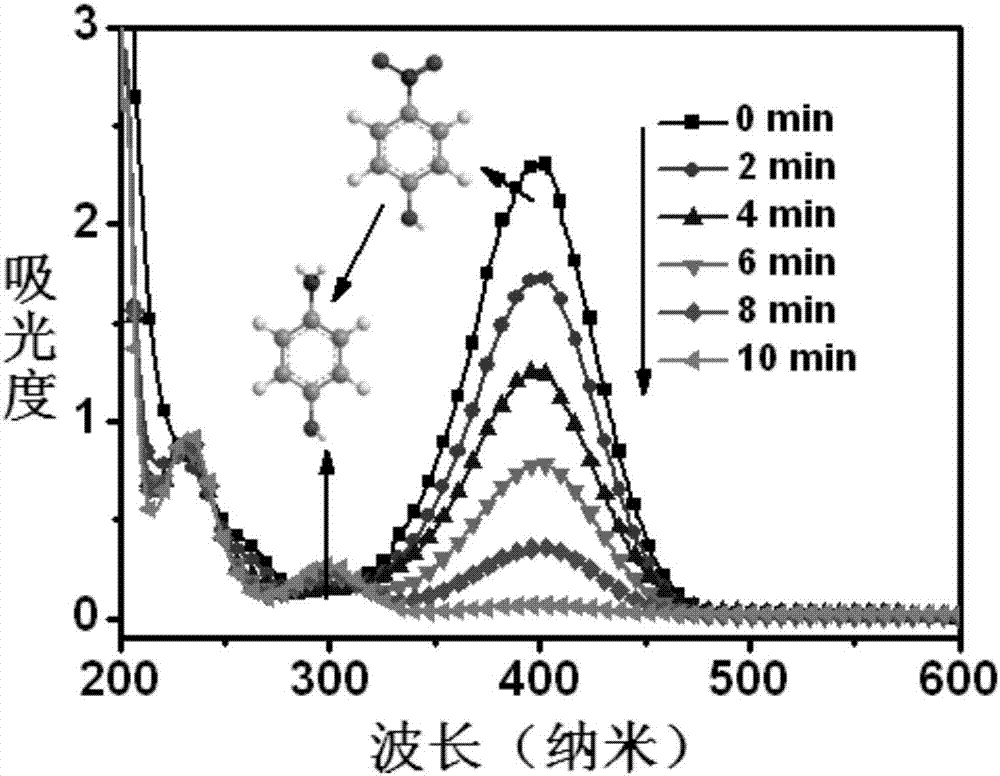

[0081] The reduction process of p-nitrophenol was tested by UV-Vis absorption spectrometer. Such as figure 2 shown in sample 1 # When used as a catalyst, the absorbance of p-nitrophenol decreased rapidly with time, while the concentration of p-aminophenol gradually inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com