Green environmentally-friendly polymer deodorant capable of efficiently degrading plurality of odorous organic substances and application of deodorant in air purification

A green, environmentally friendly, polymer technology, applied in other chemical processes, deodorization, separation methods, etc., can solve the problems of incomplete removal, slow removal speed, limited practicability, etc., and achieve significant removal effect and increased specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of bismuth vanadate

[0032] Dissolve 0.0015 mol of sodium vanadate and 0.006 mol of bismuth nitrate in deionized water respectively, drop the sodium vanadate solution into the bismuth nitrate solution drop by drop, stir for 30 minutes, let it stand for 5 hours, and put it in a constant temperature drying box After reacting at 160 degrees Celsius for 12 hours, after cooling to room temperature, continue to keep stirring and add 0.01 mol of hydrogen peroxide, filter with suction, wash and dry to obtain bismuth vanadate powder.

[0033] At room temperature, 8 parts by weight of niobium pentachloride were dissolved in 100 parts by weight of absolute ethanol to obtain a niobium pentachloride ethanol solution, which was left to stand for 15 minutes; 15 parts by weight of bismuth vanadate, 0.08 parts by weight of sulfurous acid Sodium hydrogen blocked HDI was added to the ethanol solution of niobium pentachloride, and the mixture was uniform to obtain the first mi...

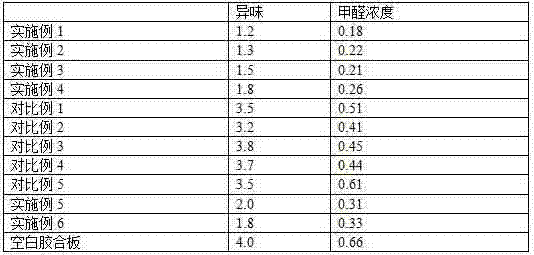

Embodiment 1

[0035] In the container of the stirring device, 100 parts by weight of the water-based hyperbranched polymer A2, 15 parts by weight of porous silica and zirconia balls are added to the container, stirred at 3000 rpm for 2 hours and then filtered to remove the zirconia balls , add 0.12 parts by weight of hydrogen peroxide, stir at 1000 rpm for 2 hours; add 6 parts by weight of the modified nano niobium oxide prepared above, stir for 1 hour at 1000 rpm, add 3 parts by weight of polyethylene glycol Stir the alcohol evenly to obtain a polymer deodorant.

Embodiment 2

[0037]In the container of the stirring device, 100 parts by weight of the water-based hyperbranched polymer A2, 24 parts by weight of porous silica and zirconia balls are added to the container, stirred at 3000 rpm for 2 hours, then filtered to remove the zirconia balls , add 0.27 parts by weight of hydrogen peroxide, stir at 1000 rpm for 2 hours; add 9 parts by weight of the modified nano niobium oxide prepared above, stir for 1 hour at 1000 rpm, add 3 parts by weight of polyethylene glycol Stir the alcohol evenly to obtain a polymer deodorant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com