Industrial preparation method of acrylate grafted polyisoprene

A technology of polyisoprene and acrylate, applied in the field of industrialized preparation of modified polyisoprene, which can solve the problems of inability to effectively dissolve polar polymerization inhibitors, unspecified purification methods of reactants, and polarity of solvent xylene Low-level problems, to achieve the effect of easy automatic management, low energy consumption for solvent recovery, and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

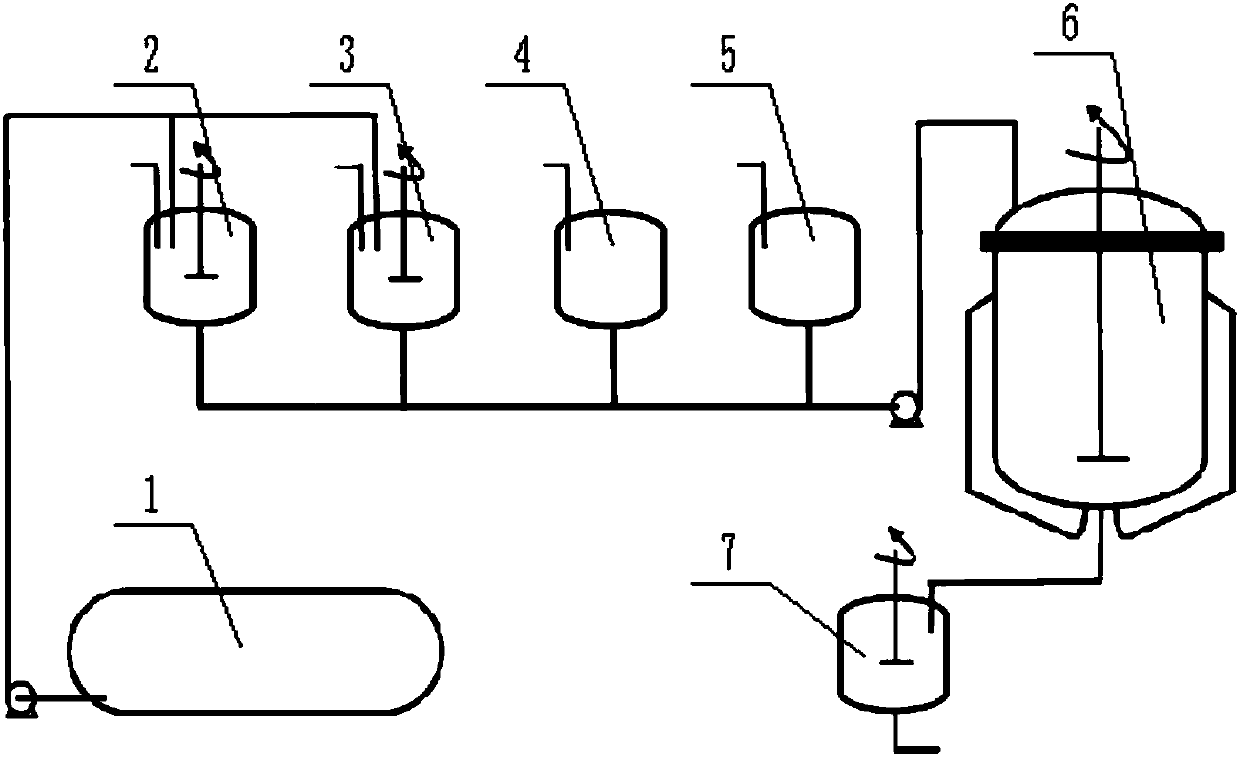

[0043] S1, introducing the solvent tetrahydrofuran into the A storage tank 1;

[0044] S2. Add 5 kg of maleic anhydride-modified polyisoprene into the first preparation tank 2, and introduce 11.2 L of solvent tetrahydrofuran into the first preparation tank 2, and stir at 30° C. to make the maleic anhydride-modified polyisoprene Isoprene is fully dissolved in the solvent;

[0045] S3. Add 0.05 kg of methyl tert-butyl ether into the second preparation tank 3, and introduce 0.06 L of solvent tetrahydrofuran into the second preparation tank 3, and stir at 20° C. to fully dissolve the polymerization inhibitor in the solvent;

[0046] S4, importing 1L of triethylamine into the B storage tank 4;

[0047] S5, importing 0.7L of hydroxyethyl methacrylate into C storage tank 5;

[0048] S6, 11.2 L of the maleic anhydride-modified polyisoprene solution prepared in step S2, 1 L of triethylamine in step S4, 0.7 L of hydroxyethyl methacrylate in step S5, and tertiary methyl methacrylate pr...

Embodiment 2

[0051] S1, introducing the solvent tetrahydrofuran into the A storage tank 1;

[0052] S2. Add 5 kg of maleic anhydride-modified polyisoprene into the first preparation tank 2, and introduce 5.6 L of solvent tetrahydrofuran into the first preparation tank 2, and stir at 40° C. to make the maleic anhydride-modified polyisoprene Isoprene is fully dissolved in the solvent;

[0053] S3. Add 0.05 kg of methyl tert-butyl ether into the second preparation tank 3, and introduce 0.03 L of solvent tetrahydrofuran into the second preparation tank 3, and stir at 30° C. to fully dissolve the polymerization inhibitor in the solvent;

[0054] S4, importing 1L of triethylamine into the B storage tank 4;

[0055] S5, importing 0.7L of hydroxyethyl methacrylate into C storage tank 5;

[0056] S6, 5.6 L of maleic anhydride-modified polyisoprene solution prepared in step S2, 1 L of triethylamine in step S4, 0.7 L of hydroxyethyl methacrylate in step S5, and tertiary methyl methacrylate prepared...

Embodiment 3

[0059] S1, introducing the solvent tetrahydrofuran into the A storage tank 1;

[0060] S2. Add 5 kg of maleic anhydride-modified polyisoprene into the first preparation tank 2, and introduce 11.2 L of solvent tetrahydrofuran into the first preparation tank 2, and stir at 30° C. to make the maleic anhydride-modified polyisoprene Isoprene is fully dissolved in the solvent;

[0061] S3. Add 0.1 kg of methyl tert-butyl ether into the second preparation tank 3, and introduce 0.11 L of solvent tetrahydrofuran into the second preparation tank 3, and stir at 20° C. to fully dissolve the polymerization inhibitor in the solvent;

[0062] S4, importing 1L of triethylamine into the B storage tank 4;

[0063] S5, importing 0.9L of hydroxyethyl methacrylate into the C storage tank 5;

[0064] S6, 11.2 L of the maleic anhydride-modified polyisoprene solution prepared in step S2, 1 L of triethylamine in step S4, 0.9 L of hydroxyethyl methacrylate in step S5, and tertiary methyl methacrylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com