Castor oil composite material and castor oil-based polyurethane elastomer prepared by using it

A technology of polyurethane elastomers and composite materials, applied in the field of castor oil-based polyurethane elastomers, which can solve problems such as poor toughness and easy disconnection, and achieve the effects of increasing elongation at break, reducing viscosity, and promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

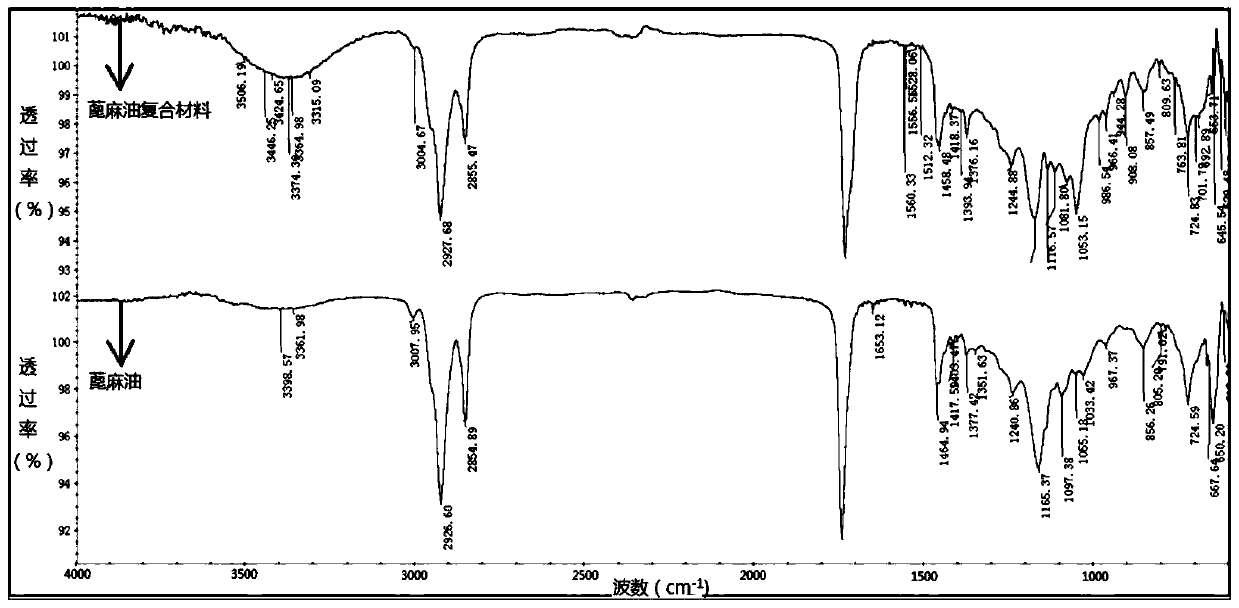

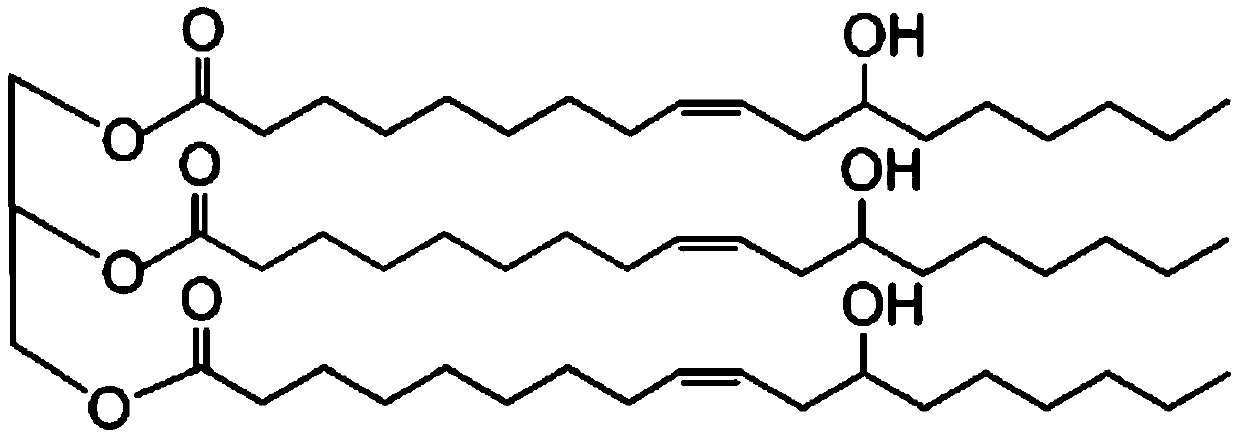

[0040] The present embodiment provides a kind of castor oil-based polyurethane elastomer, and the synthetic raw material of castor oil-based polyurethane elastomer comprises castor oil composite material 100g, liquefied diphenylmethane diisocyanate (MDI) 21g; Castor oil composite material uses castor oil, Acrylic monomers and epoxy compounds are used as raw materials.

[0041] The preparation method of above-mentioned castor oil-based polyurethane elastomer is as follows:

[0042] (1) preparation of castor oil composite material

[0043] S1. Add 190 g of castor oil into a four-necked flask with a stirring device, and raise the temperature to 50° C. After mixing 2g of methyl methacrylate, 2g of isooctyl acrylate, 6g of hydroxyethyl acrylate and 0.1g of azobisisobutyronitrile, add them dropwise to castor oil within 10 hours; h.

[0044] S2. Remove the gas and moisture in the four-necked flask, add 0.04g of potassium hydroxide and 100g of propylene oxide and ripen at 140°C for...

Embodiment 2

[0048] The present embodiment provides a kind of castor oil-based polyurethane elastomer, and the synthetic raw material of castor oil-based polyurethane elastomer comprises castor oil composite material 100g, liquefied diphenylmethane diisocyanate (MDI) 41g; Castor oil composite material uses castor oil, Acrylic monomers and epoxy compounds are used as raw materials.

[0049] The preparation method of above-mentioned castor oil-based polyurethane elastomer is as follows:

[0050] (1) preparation of castor oil composite material

[0051] S1. Add 160 g of castor oil into a four-necked flask with a stirring device, and raise the temperature to 85° C. After mixing 10g of isopropyl acrylate, 8g of isooctyl acrylate, 12g of hydroxyethyl acrylate, 10g of isobornyl methacrylate and 0.2g of azobisisoheptanonitrile, they were added dropwise to castor oil within 2 hours; After the addition is complete, keep stirring for 0.5h.

[0052] S2. Remove the gas and moisture in the four-necke...

Embodiment 3

[0056] The present embodiment provides a kind of castor oil base polyurethane elastomer, and the synthetic raw material of castor oil base polyurethane elastomer comprises castor oil composite material 100g, the diphenylmethane diisocyanate (MDI) 25g of liquefaction; Castor oil composite material uses castor oil, Acrylic monomers and epoxy compounds are used as raw materials.

[0057] The preparation method of above-mentioned castor oil-based polyurethane elastomer is as follows:

[0058] (1) preparation of castor oil composite material

[0059] S1. Add 40 g of castor oil into a four-necked flask with a stirring device, and raise the temperature to 120° C. After mixing 10g of ethyl methacrylate, 30g of butyl methacrylate, 30g of isobutyl acrylate, 50g of hydroxyethyl acrylate, 40g of methyl acrylate and 5g of azobisisobutyronitrile, they were added dropwise to castor within 8 hours. In sesame oil; after the dropwise addition is completed, keep stirring for 0.5h.

[0060] S2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com