Process for producing high-purity ammonium dimolybdate through ion exchange method

An ion exchange method, ammonium dimolybdate technology, is applied in the field of high-purity ammonium dimolybdate production by ion exchange method, which can solve the problem that the chemical properties of the product are difficult to meet the requirements of the national standard, the environmental protection discharge is difficult to meet the national requirements, and the leaching rate of industrial molybdenum oxide is not high. Advanced problems, to achieve the effect of improving labor productivity, strong adaptability of raw materials, and good impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

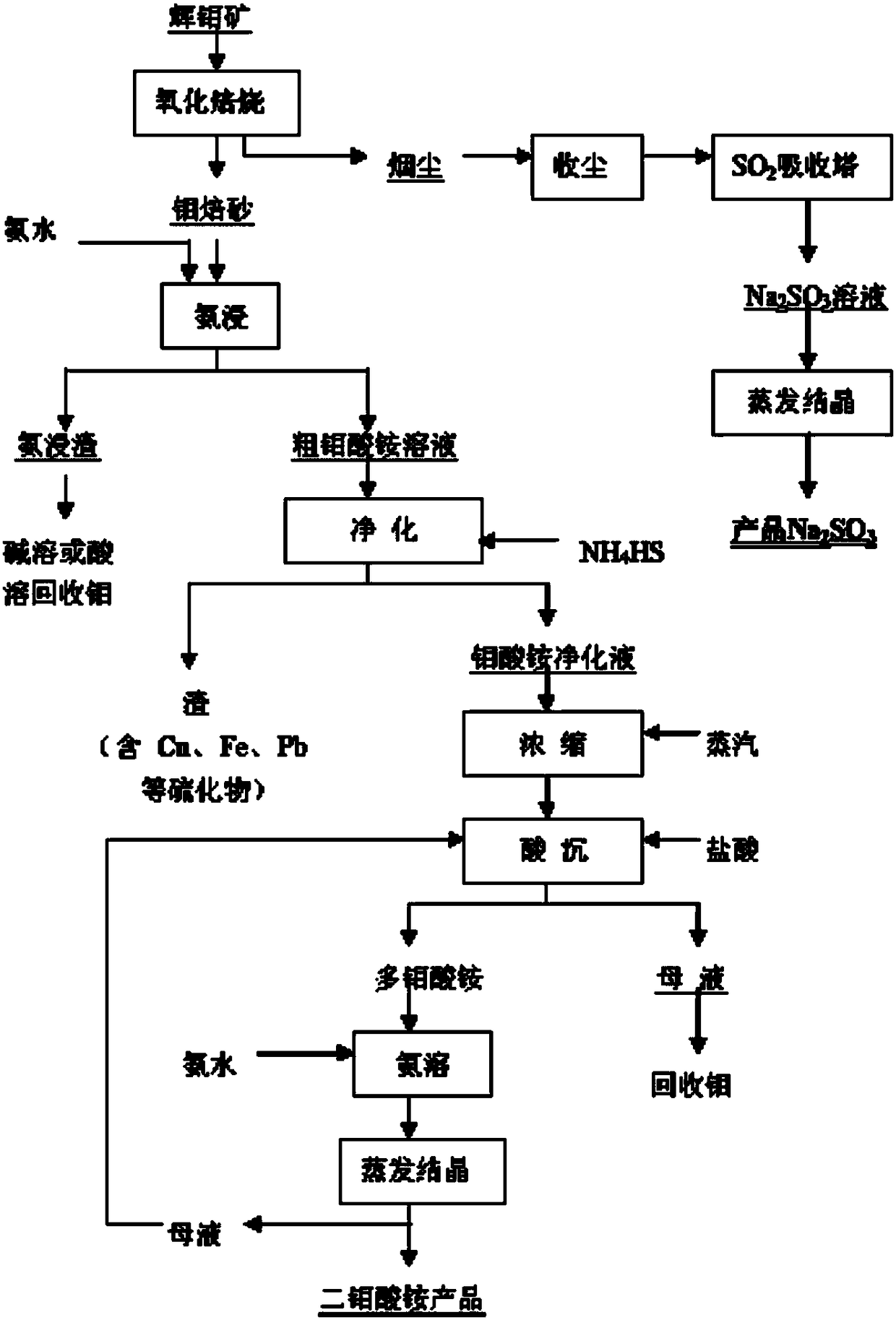

Image

Examples

Embodiment Construction

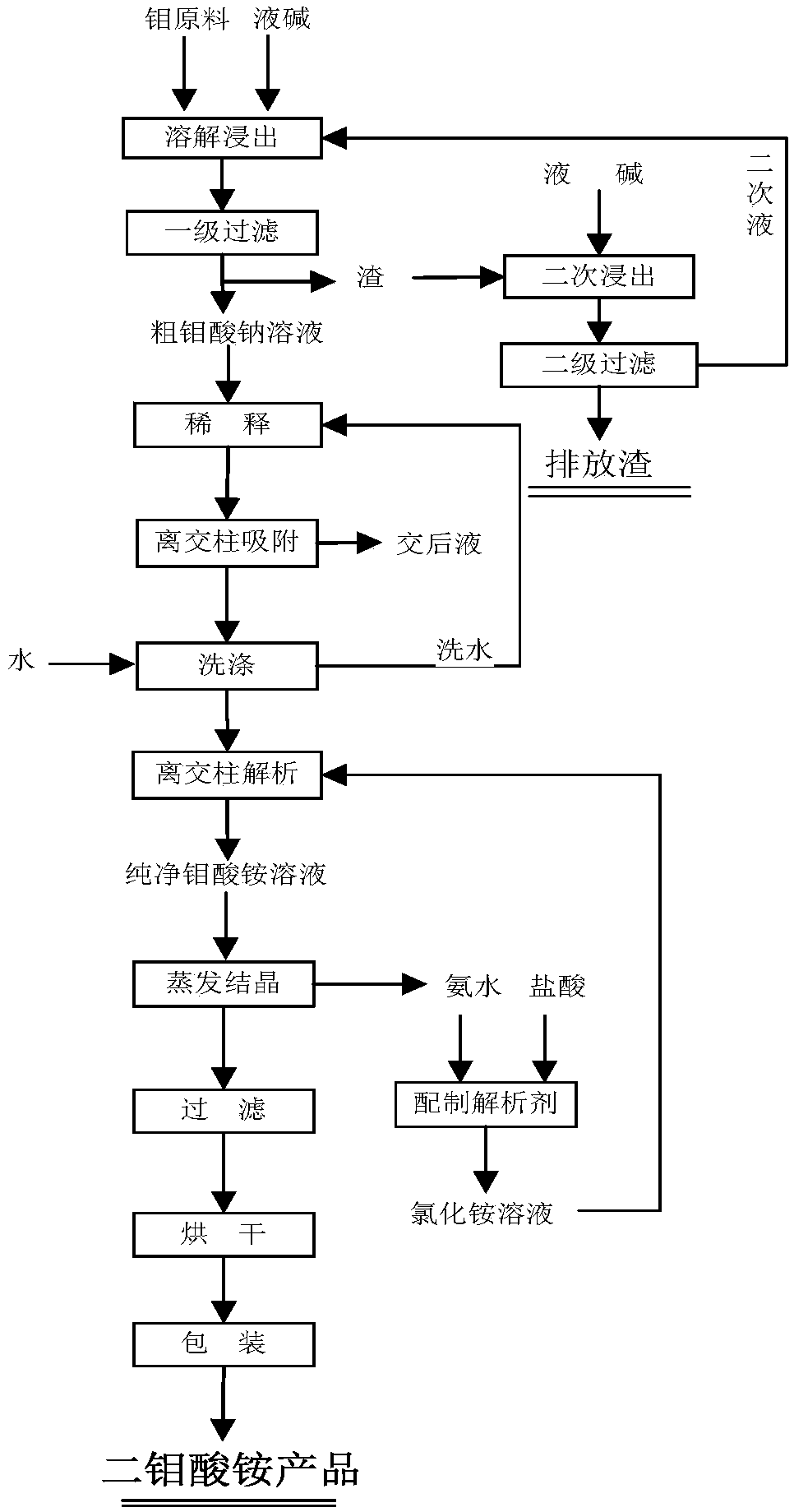

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] 1. Preparation of sodium molybdate solution

[0026] (1) Dissolving:

[0027] Molybdenum raw materials (any one or more mixtures of industrial molybdenum trioxide, molybdenum dioxide, molybdenum sulfide, molybdate) and NaOH solution in the dissolution tank with molybdenum alkali molar ratio of 1:1 ~ 1:2 Mix and react for 2-3 hours at a temperature of 70-100°C and a solid-to-liquid ratio of 1:5-1:10 to prepare a crude sodium molybdate slurry, and a part of soluble molybdenum reacts with caustic soda to form sodium molybdate and store it in Solution, another part of undissolved molybdenum dioxide, molybdenum sulfide and molybdate and other molybdenum compounds remain in the slag phase;

[0028] (2) Filtration and secondary leaching:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com