Cellulose nanofibril reinforced polyurethane fiber as well as preparation method and application thereof

A technology of polyurethane fibers and nanofibrils is applied in the direction of cellulose/protein conjugated rayon, rayon manufacturing, fiber chemical characteristics, etc., which can solve the problem of high energy consumption, large macroscopic size of fiber raw materials, and small nanowhisker size and other problems, to achieve the effects of high specific surface area, improved dyeability, and high adsorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

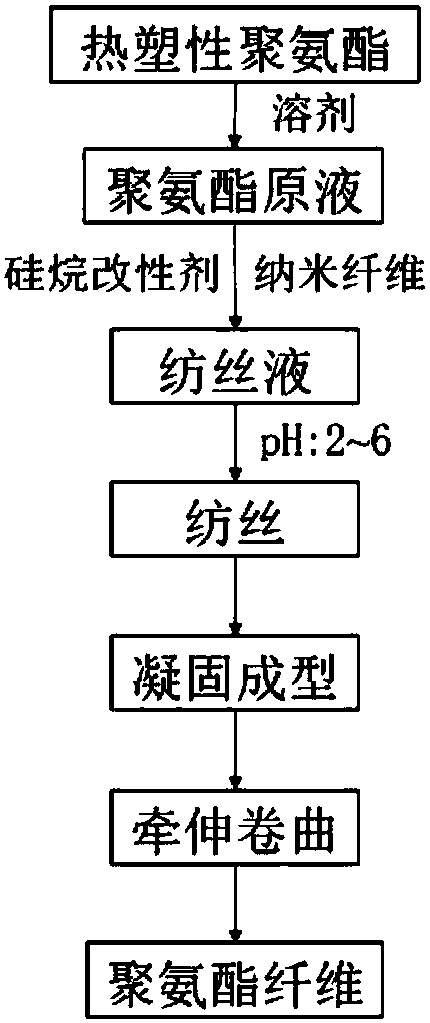

Method used

Image

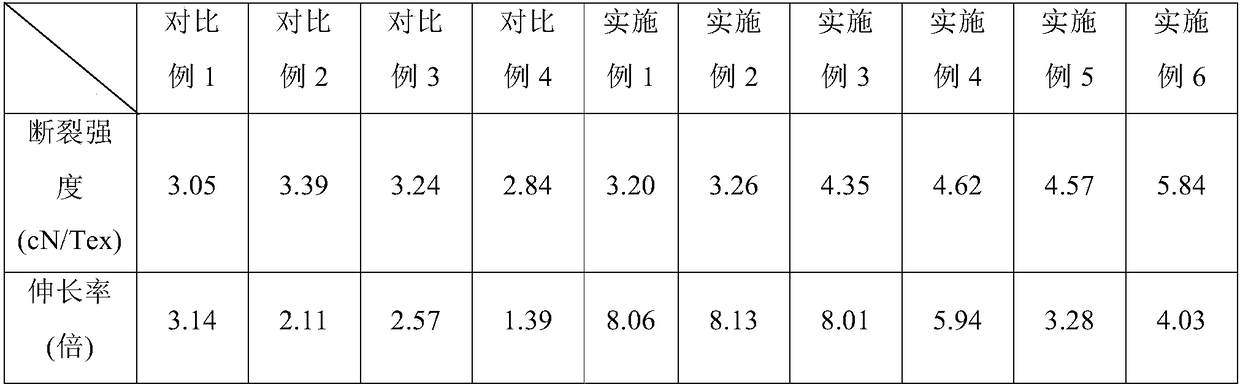

Examples

Embodiment 1

[0055] The preparation method of cellulose nanofibril reinforced polyurethane fiber is as follows:

[0056] (1) Preparation of cellulose nanofibrils: mix the plant fiber raw material with the citric acid-sodium citrate buffer solution of pH=6 at a liquid ratio of 1:25g / ml, and add the fiber with a ratio of 30IU / g to the plant fiber raw material Sulfase (Novozymes company model is The cellulase of D) was shaken at 50°C for 18h to obtain a cellulose suspension, and after filtering and washing, the filtrate was inactivated at a high temperature of 90°C. The cellulose after the above treatment is microfibrillated and refined under a pressure of 1500 Bar to obtain a micro-nano cellulose slurry with a slurry concentration of 10 wt%, and then use a high-pressure micro-jet homogenizer to process it 5 times under a pressure of 28000 Bar to obtain a micro-nano cellulose slurry with a diameter of Cellulose nanofibrils of 15 nm and 1.5 μm in length.

[0057] (2) Dissolving thermoplasti...

Embodiment 2

[0061] The preparation method of cellulose nanofibril reinforced polyurethane fiber is as follows:

[0062] (1) Preparation of cellulose nanofibrils: mix the plant fiber raw material with the citric acid-sodium citrate buffer solution of pH=7 at a liquid ratio of 1:25g / ml, add the fiber with a ratio of 20IU / g to the plant fiber raw material Sulfase (Novozymes company model is The cellulase of D) was shaken at 50°C for 24h to obtain a cellulose suspension, and after filtering and washing, the filtrate was inactivated at a high temperature of 85°C. The cellulose after the above treatment was microfibrillated and refined under a pressure of 1300 Bar to obtain a micro-nano cellulose slurry with a slurry concentration of 0.1 wt%, and then processed 5 times with a high-pressure micro-jet homogenizer at a pressure of 25000 Bar to obtain a diameter Cellulose nanofibrils of 50 nm in length and 5 μm in length.

[0063] (2) Dissolving thermoplastic polyurethane in dimethylacetamide to...

Embodiment 3

[0067] The preparation method of cellulose nanofibril reinforced polyurethane fiber is as follows:

[0068] (1) Preparation of cellulose nanofibrils: mix the plant fiber raw material with the citric acid-sodium citrate buffer solution of pH=6 at a liquid ratio of 1:35g / ml, and add the fiber with a ratio of 30IU / g to the plant fiber raw material Sulfase (Novozymes company model is The cellulase of D) was shaken at 40°C for 20h to obtain a cellulose suspension, and after filtering and washing, the filtrate was inactivated at a high temperature of 90°C. The cellulose after the above treatment is microfibrillated and refined under a pressure of 1500 Bar to obtain a micro-nano cellulose slurry with a slurry concentration of 5 wt%, and then use a high-pressure micro-jet homogenizer to process it 6 times under a pressure of 30000 Bar to obtain a micro-nano cellulose slurry with a diameter of 25 nm cellulose nanofibrils with a length of 1 μm.

[0069] (2) Dissolving thermoplastic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com