High-temperature-resistant glass and preparation method of same

A technology of high temperature resistance and glass, applied in the field of high temperature resistant glass and its preparation, can solve the problems of high melting point, high refractive index and small thermal conductivity, and achieve the effect of improving high temperature resistance, uniform texture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

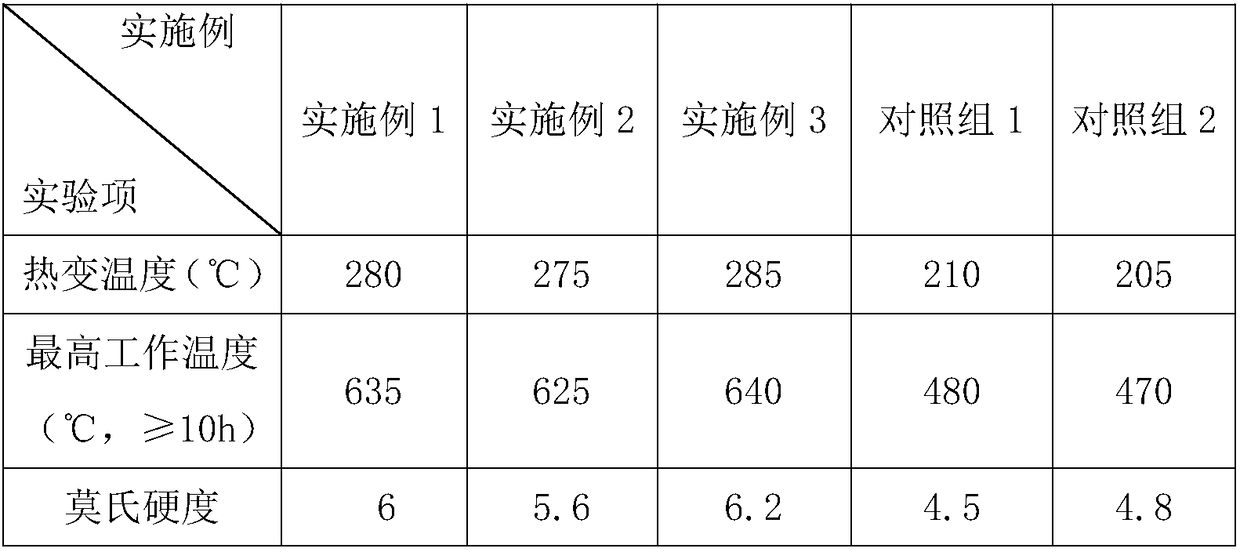

Examples

Embodiment 1

[0028] A high temperature resistant glass made of the above components by weight: 70 parts of quartz sand, 35 parts of soda ash, 25 parts of silicon dioxide, 22 parts of mica powder, 20 parts of zirconium dioxide, 15 parts of strontium carbonate, zinc borate 10 parts, 5 parts of titanium dioxide, 7 parts of silicon nitride, 5 parts of chromium trioxide, 7 parts of molybdenum oxide, 10 parts of aluminum oxide, 12 parts of tungsten-nickel alloy, 5 parts of bismuth oxide, 3 parts of awn, 2 parts of calcium aluminate 4.5 parts, 4.5 parts of cobalt oxide and 6 parts of additives.

[0029] Wherein, the auxiliary agent is prepared by mixing the following raw materials in parts by weight: 3 parts of carbon powder, 2 parts of saltpeter powder, 2 parts of magnesium nitride, and 1 part of coke powder.

[0030] A method for preparing high temperature resistant glass, comprising the following steps:

[0031] (1) Quartz sand, soda ash, silicon dioxide, mica powder, zirconium dioxide, stron...

Embodiment 2

[0043] A high-temperature-resistant glass made of the above components by weight: 60 parts of quartz sand, 30 parts of soda ash, 20 parts of silicon dioxide, 15 parts of mica powder, 10 parts of zirconium dioxide, 10 parts of strontium carbonate, zinc borate 5 parts, 3 parts of titanium dioxide, 5 parts of silicon nitride, 2 parts of chromium trioxide, 5 parts of molybdenum oxide, 5 parts of aluminum oxide, 8 parts of tungsten-nickel alloy, 3 parts of bismuth oxide, 1 part of Glauber's salt, 1 part of calcium aluminate 3 parts, 3 parts of cobalt oxide and 4 parts of additives.

[0044] Wherein, the auxiliary agent is formed by mixing the following raw materials in parts by weight: 2 parts of carbon powder, 1.5 parts of saltpeter powder, 1 part of magnesium nitride, and 0.5 part of coke powder.

[0045] A method for preparing high temperature resistant glass, comprising the following steps:

[0046] (1) Quartz sand, soda ash, silicon dioxide, mica powder, zirconium dioxide, st...

Embodiment 3

[0058] A high temperature resistant glass made of the above components by weight: 80 parts of quartz sand, 40 parts of soda ash, 30 parts of silicon dioxide, 35 parts of mica powder, 30 parts of zirconium dioxide, 20 parts of strontium carbonate, zinc borate 15 parts, titanium dioxide 8 parts, silicon nitride 10 parts, chromium trioxide 8 parts, molybdenum oxide 10 parts, aluminum oxide 15 parts, tungsten-nickel alloy 15 parts, bismuth oxide 8 parts, Glauber's salt 5 parts, calcium aluminate 3 parts 6 parts, 6 parts of cobalt oxide and 8 parts of additives.

[0059] Wherein, the auxiliary agent is formed by mixing the following raw materials in parts by weight: 4 parts of carbon powder, 3.5 parts of saltpeter powder, 3 parts of magnesium nitride, and 1.5 parts of coke powder.

[0060] A method for preparing high temperature resistant glass, comprising the following steps:

[0061] (1) Quartz sand, soda ash, silicon dioxide, mica powder, zirconium dioxide, strontium carbonate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com