A carbazolyltetraaminepyrene hole transport material and its application in perovskite solar cells

A technology for solar cells and hole transport layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of narrow selection of inorganic hole transport materials, low photoelectric conversion efficiency, etc., and achieve good hole transport performance and Electron blocking performance, good energy conversion efficiency, convenient purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

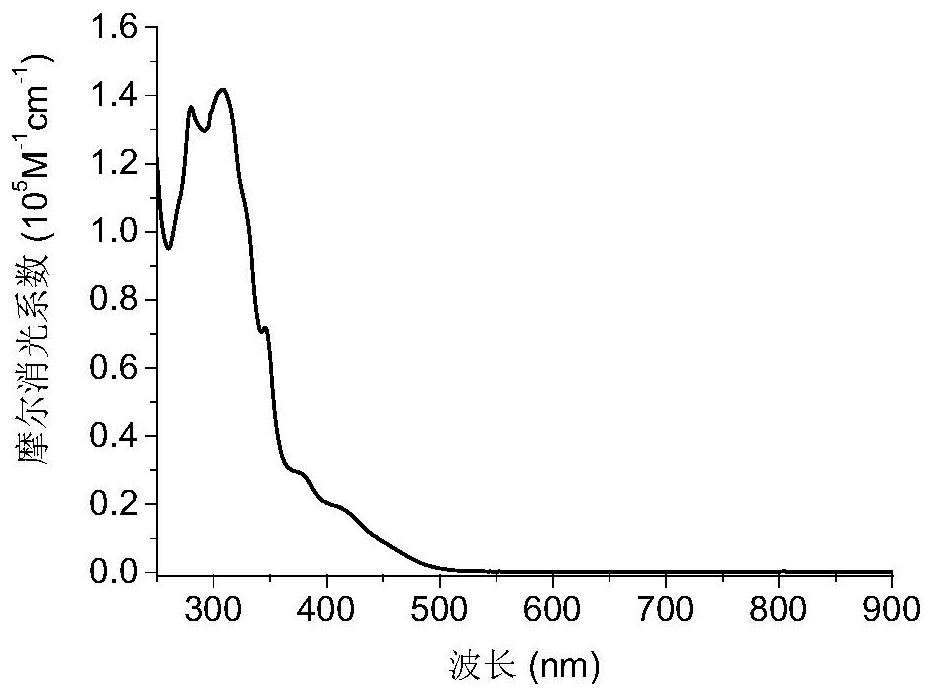

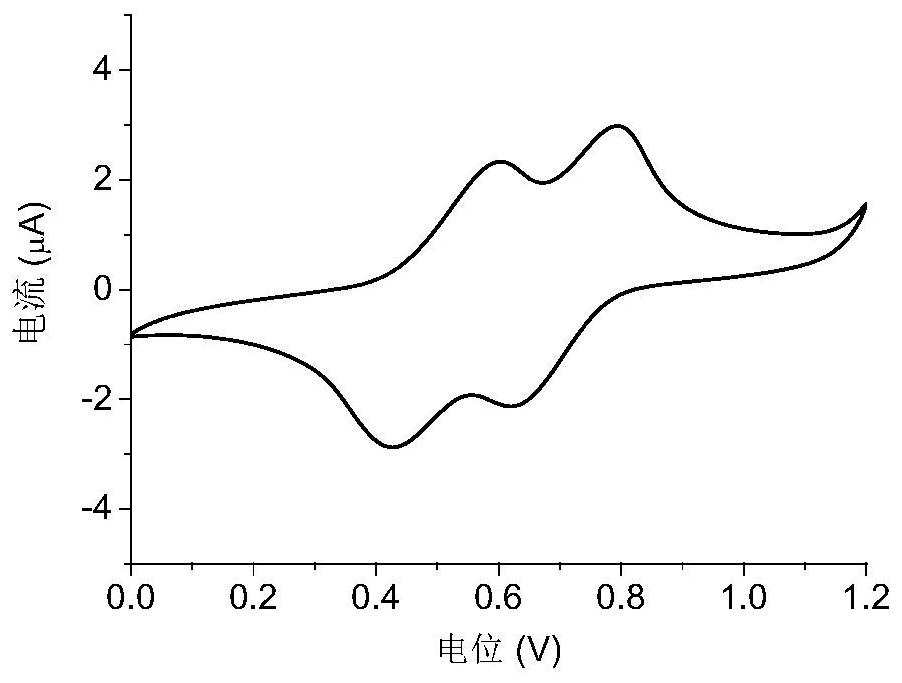

[0048] Example 1. Synthesis of a carbazolyltetraaminepyrene hole transport material having a structural unit of formula I.

[0049] A kind of chemical structural formula is the carbazolyl tetraamine pyrene hole transport material of I, and its synthetic route is as follows:

[0050]

[0051] Synthesis of compound a:

[0052] Dissolve 110mg of 3,6-dibromocarbazole and 116mg of di-tert-butyl dicarbonate in 10mL of tetrahydrofuran, add 8mg of 4-dimethylaminopyridine and heat to reflux for 3 hours. Cool to room temperature after the reaction, and spin dry the solvent under reduced pressure. Separation and purification by column chromatography (eluent: dichloromethane) gave compound a with a yield of 90%.

[0053] Step b:

[0054] Dissolve 280mg 4,4'-dimethoxydiphenylamine, 250mg compound a and 170mg potassium tert-butoxide in toluene, add 1,1'-bisdiphenylphosphinoferrocene and tri(di benzylideneacetone) dipalladium, heated to reflux for 5 hours. After cooling, the solvent ...

Embodiment 2

[0060] Example 2. Synthesis of a carbazolyltetraaminepyrene hole transport material having a structural unit of formula II.

[0061] A kind of chemical structure formula is the carbazolyl tetraamine pyrene hole transport material of II, and its synthetic route is as follows:

[0062]

[0063] Synthesis of hole-transporting materials with the structure of formula II:

[0064] 250mg (0.40mmol) tetrakis (4-methoxyphenyl) -9H-carbazole-3,6-diamine, 70mg (0.14mmol) 1,3,6,8-tetrabromopyrene, 6mg (0.026mmol ) Palladium acetate and 150 mg (1.08 mmol) of potassium carbonate were dissolved in 15 mL of toluene, and heated to reflux for 24 hours under nitrogen protection. Extract three times with dichloromethane, dry the organic phase with anhydrous magnesium sulfate, remove the solvent by rotary evaporation, separate and purify by column chromatography (eluent: petroleum ether / ethyl acetate 2 / 1, v / v) to obtain the target product II , the yield was 27%. MALDI-TOF: 2680.7 for [M] + ...

Embodiment 3

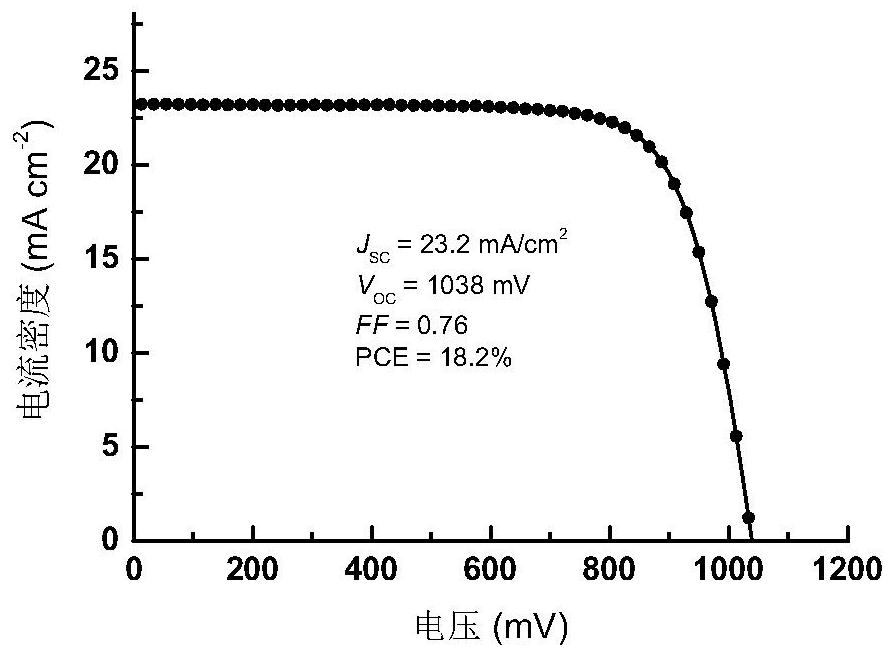

[0066] Embodiment 3, utilize the compound shown in formula I and formula II obtained in embodiment 1 and embodiment 2 to prepare perovskite solar cell

[0067] The specific steps include: ultrasonicating the FTO conductive glass with deionized water, detergent, acetone, and ethanol for 15 minutes, then drying with nitrogen, and UVO treatment for 30 minutes before spin-coating the dense layer. A dense layer with a thickness of 50 nm and a mesoporous layer with a thickness of 150 nm were spin-coated on the FTO conductive glass by spin coating, and heat-treated at 500° C. for 30 minutes. After natural cooling, the perovskite solution was spin-coated on the mesoporous layer, and annealed at 100° C. for 5 minutes to obtain a perovskite layer with a thickness of 300 nm. The solution of the carbazolyltetraaminepyrene hole transport material shown in formula I or formula II was dropped onto the perovskite layer, left to stand for about 10 seconds, and then spin-coated to obtain a hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com