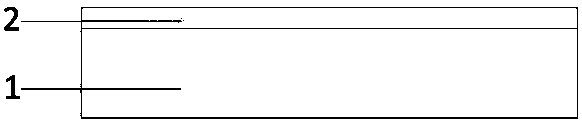

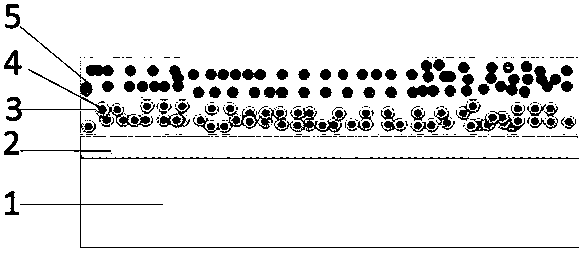

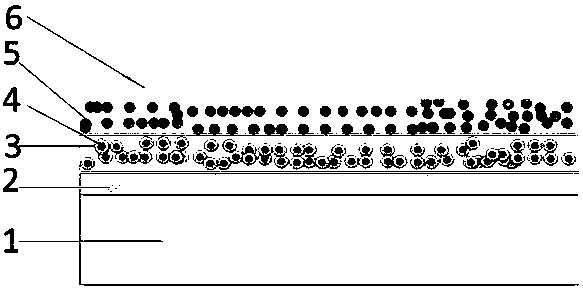

Preparation method of noble metal/SiO2 composite particle and semi-conductor quantum dot laminated quantum dot luminescent thin film

A technology of quantum dot luminescence and composite particles, which is applied in chemical instruments and methods, luminescent materials, nano-optics, etc., can solve problems such as difficult to meet, achieve low production cost, novel preparation method, and improve photoluminescence performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 0.049g of CuI and 0.292g of indium acetate respectively, take 10ml of ODE with a graduated cylinder and add them to the three-necked flask in turn, first blow at 500rpm with nitrogen for 10min, then heat to 120°C, keep After 30 minutes, inject 6ml of DDT, heat to 230°C (8 minutes), and time at 230°C for 5 minutes.

[0033] (2) Take 1.467g of zinc acetate, 8ml of OA and 4ml of ODE and heat them to 190°C for 30min until completely dissolved to form a transparent solution. The precursor solution of Zn can be obtained;

[0034](3) The precursor of Zn was injected into the precursors of CuI and indium acetate at a rate of 1ml / min, and then the temperature was raised to 240°C and kept for 1h. Then remove from heat and cool to room temperature. The methanol solution is injected into the mixed solution to obtain the corresponding nanocrystal precipitation, and after centrifugation and washing, the obtained CuInS / ZnS semiconductor quantum dots are dispersed into the ...

Embodiment 2

[0040] (1) Weigh 0.1534g of CuI powder and 0.9332g of indium acetate powder, take 2ml of DDT, 1ml of OA and 20ml of ODE, degas under argon for 20min, then heat to 120°C (keep for 30min) and then Heat to 230°C for 15 minutes.

[0041] (2) Heat 1.317g of zinc acetate dihydrate, 4ml of oleylamine and 12ml of ODE to 110°C for 30min until completely dissolved to form a transparent solution. The precursor solution of Zn can be obtained;

[0042] (3) The precursor of Zn was injected into the precursors of CuI and indium acetate at a rate of 1ml / min, and then the temperature was raised to 240°C and kept for 3h. Then remove from heat and cool to room temperature. The ethanol solution is injected into the mixed solution to obtain the corresponding nanocrystal precipitation, and after centrifugation and washing, the obtained CuInS / ZnS semiconductor quantum dots are dispersed into the chloroform or toluene solution.

[0043] (4) Measure 100ml of chloroauric acid (0.01wt%) with a measur...

Embodiment 3

[0048] (1) Weigh 0.024g of CuI powder and 0.146g of indium acetate powder, take 5ml of ODE, first degas under argon for 20min, then heat to 120°C (hold for 30min), then heat to 230°C for 5min.

[0049] (2) Take 0.878g of zinc acetate dihydrate, 4ml of oleic acid and 2ml of ODE and heat to 160°C for 30min until completely dissolved to form a transparent solution. The precursor solution of Zn can be obtained;

[0050] (3) The precursor of Zn was injected into the precursors of CuI and indium acetate at a rate of 1ml / min, and then the temperature was raised to 230°C and kept for 3h. Then remove from heat and cool to room temperature. The ethanol solution is injected into the mixed solution to obtain the corresponding nanocrystal precipitation, and after centrifugation and washing, the obtained CuInS / ZnS semiconductor quantum dots are dispersed into the chloroform or toluene solution.

[0051] (4) Measure 100ml of chloroauric acid (0.01wt%) with a measuring cylinder and add it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com